SiC MOSFET vs Silicon MOSFET Performance and Efficiency Comparison

Explore the SiC MOSFET vs Traditional Silicon MOSFET performance comparison focusing on efficiency, thermal management, and switching speed for power electronics.

If you’re evaluating whether to upgrade your power electronics designs, understanding the performance differences between SiC MOSFETs and traditional Silicon MOSFETs is critical. Engineers and decision-makers face the challenge of balancing higher SiC costs against significant efficiency gains, thermal advantages, and switching speed improvements. This comparison isn’t just about specs—it’s about unlocking system-level benefits that drive down size, weight, and energy loss in applications like EV inverters and solar inverters. In this article, we’ll dive straight into the key technical metrics and real-world impacts that make Silicon Carbide a compelling choice for next-generation power electronics.

The Material Science: Why Wide Bandgap Matters

When comparing SiC MOSFETs to traditional silicon MOSFETs, the core difference lies in the wide bandgap semiconductor material. Silicon Carbide (SiC) has a bandgap energy of about 3.26 eV, significantly higher than silicon’s 1.12 eV. This wider bandgap fundamentally enables SiC devices to operate at much higher voltages and temperatures, making them ideal for high-voltage power modules used in demanding applications.

Bandgap Energy and High-Voltage Operation

The larger bandgap energy in SiC reduces intrinsic carrier concentration, which improves device stability under extreme conditions. This translates into:

- Higher breakdown voltage ratings: SiC MOSFETs handle voltages above 1200 V with ease.

- Lower leakage currents: Devices maintain performance at elevated junction temperatures (Tj).

- Increased robustness: Suitable for harsh environments where silicon devices struggle.

Breakdown Electric Field: Thinner Drift Layers, Lower Resistance

SiC’s critical breakdown electric field is roughly 10 times greater than silicon’s. This allows power transistor designs with:

- Thinner drift layers: Reducing on-state resistance (RDS(on)) without sacrificing voltage ratings.

- Lower conduction losses: Contributing to overall system efficiency improvements.

- Improved power density: Smaller device footprints enable compact high-voltage designs.

Thermal Conductivity: Better Heat Dissipation

One of SiC’s standout material properties is its superior thermal conductivity—approximately 3.7 W/cmK, compared to silicon’s 1.5 W/cmK. This benefit:

- Supports higher junction temperatures without performance degradation.

- Reduces thermal resistance (Rth), enhancing heat dissipation.

- Allows smaller, lighter heat sinks and more compact packaging solutions, such as HIITIO’s advanced thermal interface materials.

- Improves reliability under continuous high-power operation.

In , SiC’s wide bandgap, high breakdown field, and excellent thermal conductivity form the foundation for MOSFET performance that surpasses traditional silicon devices. These material science advantages directly translate to better efficiency, smaller size, and higher reliability in modern power electronics.

Key Performance Metrics: The Head-to-Head Comparison

When comparing SiC MOSFETs with traditional silicon MOSFETs, key metrics like on-state resistance, switching speed, and thermal management highlight the real-world benefits of SiC technology.

On-State Resistance (RDS(on)) & Temperature Stability

- SiC MOSFETs feature significantly lower RDS(on), reducing conduction losses and improving efficiency.

- Unlike silicon devices, SiC maintains stable resistance even at higher junction temperatures, which means better performance in hot environments.

- Silicon MOSFETs tend to see RDS(on) rise sharply with temperature, increasing power losses and heat generation.

| Metric | SiC MOSFET | Silicon MOSFET |

|---|---|---|

| RDS(on) at 25°C | Low (e.g., <10 mΩ) | Higher (e.g., >20 mΩ) |

| RDS(on) at 150°C | Slight increase | Significant increase |

| Conduction Losses | Lower | Higher |

Switching Speed and Frequency

- SiC devices excel with lower gate charge (Qg) and minimal reverse recovery charge (Qrr), which translates to faster switching speeds and less switching loss.

- This enables higher operating frequencies, allowing power converters to be more compact and efficient.

- Silicon MOSFETs typically have higher Qg and Qrr, limiting high-frequency performance due to increased switching losses.

Thermal Management & Power Density

- SiC’s superior thermal conductivity and higher junction temperature (Tj) limits allow devices to run hotter without failure.

- This results in smaller heat sinks and more compact system designs with higher power density.

- Innovative packaging solutions like HIITIO power modules optimize heat dissipation and ease integration for compact, high-performance applications. You can learn about the benefits of these advanced modules in HIITIO packaging insights.

In , SiC MOSFETs deliver lower conduction and switching losses, better temperature resilience, and higher power density compared to traditional silicon MOSFETs — key advantages driving their adoption in demanding U.S. markets like EVs and industrial automation.

System-Level Impact: Beyond the Datasheet

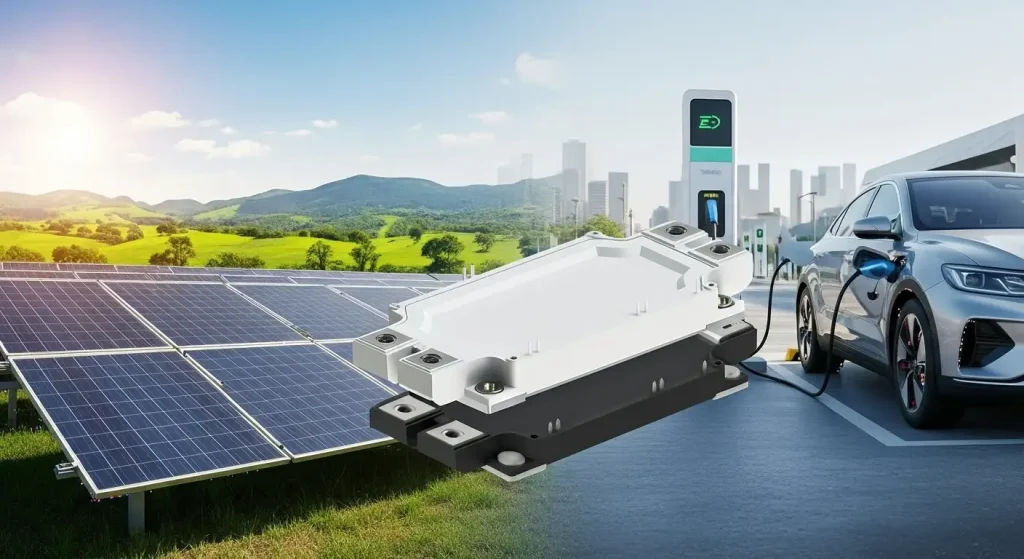

SiC MOSFETs deliver real-world efficiency gains that go beyond just the numbers on the datasheet. For example, electric vehicle (EV) traction inverters equipped with SiC devices often see efficiency improvements of 2-5% compared to traditional silicon MOSFETs. This might sound small, but it translates to longer driving range and less wasted energy. Similarly, renewable energy systems like solar inverters benefit from these improvements by boosting overall system efficiency and reducing operating costs.

One standout advantage of SiC MOSFETs is their ability to switch at much higher frequencies due to lower gate charge (Qg) and reduced reverse recovery charge (Qrr). This higher switching speed enables designers to shrink passive components such as inductors and capacitors. Smaller magnetics reduce board space and system weight—crucial for compact power modules. However, these gains bring increased gate driver complexity. SiC MOSFETs often require specialized gate driver ICs and precise biasing to manage fast switching transitions reliably.

Faster switching speeds also increase electromagnetic interference (EMI) and parasitic effects if the PCB layout isn’t optimized carefully. Proper parasitic inductance mitigation and EMI management become a must to maintain stable operation and protect sensitive circuits. Effective layout strategies and gate driver circuit optimization help tame these challenges, making high-performance SiC power modules a viable option for demanding applications.

For instance, when integrating SiC MOSFETs into high-voltage power modules, considering thermal resistance (Rth) and switching losses is key to avoiding reliability issues. Solutions like advanced press-pack packages, similar to those offered in HIITIO’s 4500V 2000A LGBT module, provide both efficient thermal management and robust electrical performance, supporting these system-level benefits.

Application Suitability: When to Choose SiC

Silicon carbide (SiC) MOSFETs shine in applications where performance, efficiency, and reliability under tough conditions matter. Here’s a quick look at where SiC really stands out:

| Application | Why Choose SiC? | Examples |

|---|---|---|

| Electric Vehicles | Higher efficiency and thermal stability for traction inverters and onboard chargers reduce size and improve range. | EV traction inverters, onboard chargers with tough thermal requirements. Check modules like the 2300V half-bridge SiC MOSFET module for high-voltage needs. |

| Renewable Energy | SiC MOSFETs handle high-voltage solar inverters and energy storage with lower conduction losses and better heat dissipation. | Photovoltaic (PV) inverter systems and large-scale energy storage installations benefit from SiC’s efficiency. |

| Industrial Automation | Superior thermal reliability and fast switching improve servo drives and robotics performance in demanding environments. | High-power servo drive controls and robotic actuators where long-term reliability under high junction temperature (Tj) is critical. |

| Power Supplies | High-frequency switching and low conduction loss cut size and improve efficiency in server modules and SMPS. | High-frequency SMPS and data center power supplies that demand tight thermal management and smaller passive components. |

SiC’s wide bandgap nature results in better breakdown voltage ratings and thermal resistance (Rth), making it perfect for these demanding fields. When you choose SiC, you’re investing in improved system efficiency, power density, and long-term reliability over traditional silicon MOSFETs.

Cost Analysis: Component Price vs. System Value

SiC MOSFETs still carry a higher upfront unit cost compared to traditional silicon MOSFETs. This price difference mainly comes from the more complex manufacturing process of wide bandgap semiconductors and the smaller production volumes. However, simply looking at the component cost doesn’t tell the full story.

When you consider the ROI benefits, SiC MOSFETs can lead to significant savings over the system lifecycle. Their lower on-state resistance (RDS(on)) and superior thermal conductivity reduce the need for bulky cooling systems, cutting both material and operational expenses. Additionally, their high switching frequencies enable smaller passive components, trimming down the size and cost of magnetics. This contributes to a leaner, more efficient power module design, such as those found in advanced power electronics assemblies.

From a broader market perspective, wide bandgap technology is gaining traction rapidly. The cost of SiC devices continues to fall thanks to improvements in wafer quality and manufacturing scale. This trend makes high-voltage SiC MOSFETs more accessible in applications like EV traction inverters and solar inverters. For example, power modules similar to the high-performance 1200V, 450A IGBT power modules are seeing SiC-based alternatives emerge, offering better efficiency despite higher initial costs.

In , while SiC MOSFETs start off pricier, the overall system value they deliver through conduction loss reduction, better thermal management, and higher reliability justifies the investment for many high-performance power electronics applications in the U.S. market.