Advantages of SiC Discrete MOSFETs for High-Voltage Power Electronics

Discover the advantages of SiC discrete MOSFETs in high-voltage power electronics for improved efficiency, thermal performance, and power density.

The Physics of Performance: Why SiC Outperforms Silicon — Wide Bandgap Explained

Why is Silicon Carbide (SiC) revolutionizing high-voltage power electronics? The answer lies in its wide bandgap properties, which give SiC MOSFETs a distinct physical edge over traditional silicon devices.

A wide bandgap semiconductor like SiC has a larger energy gap between its valence and conduction bands compared to silicon. This wider gap means SiC can withstand higher electric fields without breaking down, resulting in higher breakdown voltage stability. For power systems, this translates into devices that handle high voltages more efficiently and reliably.

Because of the wide bandgap:

- Higher temperature operation is possible without performance degradation.

- Lower leakage current occurs, improving energy efficiency.

- Faster switching speeds are achievable with less loss.

- Combined, these factors enable low RDS(on) performance and reduce switching losses, making SiC MOSFETs the superior choice for high-voltage discrete power devices. This is why wide bandgap semiconductors, especially SiC, are becoming the backbone of next-generation power electronics, from EV onboard chargers to solar PV inverters.

By choosing SiC discrete MOSFETs, we tap into these physics-based advantages that silicon simply can’t match, pushing efficiency and reliability to new levels in high-voltage applications.

The Physics of Performance: Why SiC Outperforms Silicon

Drastic Reduction in On-State Resistance (RDS(on))

One of the major reasons SiC discrete MOSFETs outperform traditional silicon devices is their drastically lower on-state resistance (RDS(on)). A lower RDS(on) means less power is lost as heat during conduction, which directly improves efficiency and reduces cooling requirements. For high-voltage applications, this reduction is critical—it allows power electronics systems to operate cooler and more reliably, even under heavy loads.

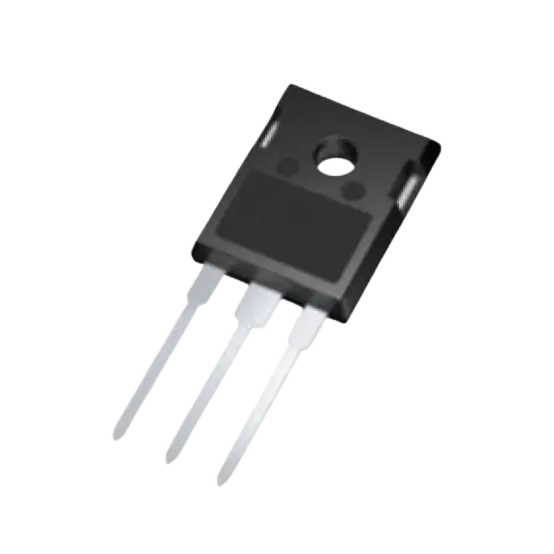

Silicon carbide’s wide bandgap properties enable devices to maintain low RDS(on) values at higher voltages without compromising performance. This means designers can push their power levels further with less concern about conduction losses. In turn, this leads to smaller, lighter, and more efficient power modules, especially when packaged in reliable discrete formats like the TO-247.

By cutting down conduction losses, SiC MOSFETs from HIITIO help improve system efficiency across the board—from electric vehicle onboard chargers to industrial power supplies. For more on how SiC modules integrate seamlessly into power electronics, you can check out our 1200V SiC power module designed for optimized low RDS(on) performance.

Key benefits of lower RDS(on) with SiC discrete MOSFETs include:

- Reduced conduction losses for higher system efficiency

- Lower heat generation, easing thermal management challenges

- Improved current-carrying capability under high voltage stress

Overall, the drastic reduction in RDS(on) makes SiC MOSFETs a game-changer in high-voltage power electronics, offering both performance and reliability gains that silicon simply can’t match.

The Physics of Performance: Why SiC Outperforms Silicon – Thermal Conductivity & Temperature Stability

Silicon Carbide (SiC) stands out for its excellent thermal conductivity, which is about three times higher than traditional silicon. This means SiC MOSFETs can transfer heat away from the junction much faster, significantly reducing junction-to-case thermal resistance. As a result, devices run cooler and maintain performance even under harsh conditions, improving reliability in high-voltage applications.

On top of thermal management, SiC offers superior temperature stability. Unlike silicon, its electrical properties remain stable at elevated temperatures, allowing devices to operate safely at junction temperatures exceeding 175°C. This makes SiC MOSFETs ideal for demanding environments like electric vehicles and industrial power supplies, where heat generation is high and consistent operation is critical.

These thermal advantages reduce the need for bulky and expensive cooling systems, boosting system-level power density and enabling more compact designs. For designers working on next-gen power electronics, especially in high-voltage setups, leveraging the thermal benefits of SiC discrete MOSFETs is a key factor in performance and efficiency.

For optimized solutions in this space, the HIITIO 1200V Silicon Carbide Schottky Diode pairs well with SiC MOSFETs to further enhance thermal management and efficiency in power electronics.

Critical Advantages in Power Electronics Design: Minimizing Switching Losses at High Frequencies

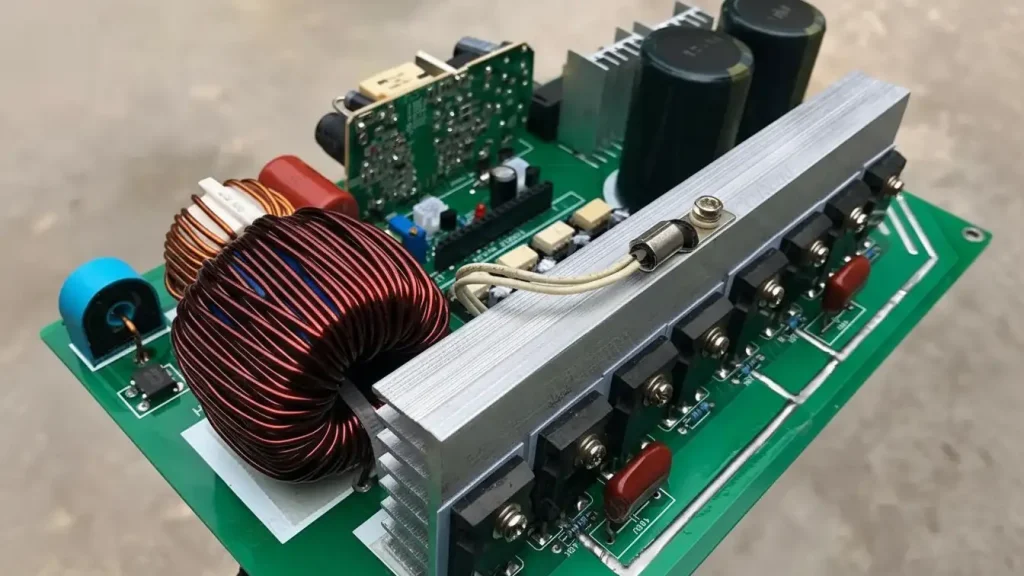

One of the biggest benefits of SiC discrete MOSFETs in high-voltage power electronics is their ability to drastically reduce switching losses, especially at high frequencies. Thanks to the wide bandgap semiconductor properties of silicon carbide, these devices switch faster and cleaner compared to traditional silicon MOSFETs. This means lower energy lost during turn-on and turn-off transitions, which is critical in hard switching topologies used in EV onboard chargers and industrial power supplies.

Low switching losses not only boost overall system efficiency but also allow power electronics to run at higher frequencies without excessive heat buildup. This opens doors for shrinking passive components like inductors and capacitors, leading to a more compact and lighter power stage, enhancing system-level power density.

HIITIO’s SiC MOSFETs, often housed in rugged discrete packages like TO-247, capitalize on this advantage by maintaining low gate charge and fast switching speeds without compromising reliability. Their design also supports optimized gate driver circuits, further minimizing switching losses and improving performance.

For systems demanding tough high-frequency operation paired with high voltage ratings, explore HIITIO’s 2300V half-bridge SiC MOSFET modules, which exemplify these switching performance benefits in demanding environments.

Key benefits minimizing switching losses at high frequencies:

- Reduced energy loss during switching transitions

- Ability to run at higher switching frequencies with less heat

- Smaller, lighter passive components for compact system design

- Supports optimized gate drive for efficient operation

- Enhances overall power density in high-voltage applications

VIEW HIITIO SIC MOSFET

Critical Advantages in Power Electronics Design: Superior Reverse Recovery

One of the standout advantages of SiC discrete MOSFETs in high-voltage power electronics is their superior reverse recovery performance. Unlike traditional silicon MOSFETs, SiC devices exhibit a very low reverse recovery charge (Qrr), which means they can switch off faster with minimal energy loss during the transition from conduction to blocking state.

This sharp reduction in reverse recovery charge reduces switching losses significantly, especially in hard switching topologies common in high-frequency power converters. As a result, systems using SiC MOSFETs benefit from improved efficiency and less heat generation, which translates to simpler thermal management and smaller cooling systems.

Moreover, the excellent reverse recovery characteristics help minimize voltage spikes and electromagnetic interference (EMI), ensuring reliability and stable operation in sensitive applications such as electric vehicle (EV) onboard chargers and renewable energy inverters.

For designers focused on optimizing power electronics, these benefits make devices like the HIITIO 1200V SiC MOSFET in a TO-247 discrete package an ideal choice to meet the demands of modern, high-frequency switching power supplies.

Explore the details of our high-performance 1200V SiC power MOSFET TO-247 for more insight into reduced reverse recovery losses.

Critical Advantages in Power Electronics Design: System-Level Power Density

One of the standout benefits of SiC discrete MOSFETs in high-voltage power electronics is their ability to significantly boost system-level power density. Thanks to the wide bandgap (WBG) properties of silicon carbide, these devices handle higher voltages and currents with much lower on-state resistance (RDS(on)) and reduced switching losses. That means you can shrink the size of heat sinks, cut down cooling requirements, and design more compact, lighter powertrains—perfect for demanding applications like EV onboard chargers and solar PV inverters.

Increasing power density isn’t just about packing more power into less space. It also drives better efficiency and thermal management. With the superior thermal conductivity of SiC and lower junction-to-case thermal resistance, the device stays cooler even at high switching frequencies. This allows for more aggressive switching speeds without sacrificing reliability, which ultimately enhances the power density of the entire system.

Discrete packages like the TO-247 are key here—they offer robust thermal paths and flexible mounting options, enabling system designers to optimize layout for both performance and footprint. This approach helps deliver the power needed in tight industrial power supply enclosures or high-performance renewable energy setups.

For detailed specs on robust SiC discrete MOSFETs optimized for high power density applications, consider exploring HIITIO’s 1200V 75mΩ silicon carbide power MOSFET in the TO-247 package, crafted to maximize efficiency and system integration in high-voltage designs.

Explore 1200V 75mΩ SiC MOSFET TO-247 package

The Strategic Value of Discrete Packages (vs. Modules): Design Flexibility

Using SiC discrete MOSFETs in TO-247 or similar packages provides unmatched design flexibility compared to power modules. Engineers can customize layouts to fit specific circuit requirements, making it easier to optimize for space, thermal management, and electrical performance. Discrete devices allow more control over PCB placement and heat sinking, which is critical in high-voltage power electronics where minimizing parasitic inductance and improving junction-to-case thermal resistance directly impact overall efficiency.

This flexibility is especially valuable in applications like EV onboard chargers (OBC) or solar PV inverters, where tailored solutions can improve power density and reduce component count. Moreover, discrete SiC MOSFETs simplify gate driver optimization and EMI mitigation strategies, enabling designers to fine-tune gate drive parameters without the constraints of predefined power modules. For a deeper dive into integration approaches with gate drivers, see our guide on the integration of power modules with gate drivers.

In , choosing discrete SiC MOSFETs offers a versatile platform that adapts to evolving design needs, delivering efficient, reliable high-voltage power electronics with a strong emphasis on customization and performance.

The Strategic Value of Discrete Packages (vs. Modules) – Cost-Effectiveness

When it comes to high-voltage power electronics, choosing SiC discrete MOSFETs in TO-247 or similar packages offers notable cost advantages over full power modules. Discrete devices allow designers to optimize system cost by selecting only the components they need, avoiding the premium price tags associated with integrated modules.

Key cost benefits include:

- Lower upfront component cost: Discrete SiC MOSFETs deliver high-performance wide bandgap benefits with a smaller initial investment.

- Simplified thermal and PCB design: Discrete packages like TO-247 reduce complexity, helping lower manufacturing and assembly costs.

- Flexible scaling: You can easily combine multiple discrete transistors in parallel or series per specific application needs without being locked into expensive module form factors.

- Reduced system-level losses: Lower RDS(on) and switching losses of HIITIO discrete SiC MOSFETs decrease cooling requirements, further cutting expenses throughout the power train lifecycle.

These cost efficiencies make discrete SiC MOSFETs an attractive choice for applications such as EV onboard chargers (OBC) and industrial power supplies, where balancing performance and budget is critical.

Choosing discrete SiC MOSFETs positions your design for both high reliability and practical cost control without sacrificing the advantages of wide bandgap technology.

The Strategic Value of Discrete Packages (vs. Modules)

Kelvin Source Implementation

One key advantage of SiC discrete MOSFETs, especially in TO-247 and similar packages, is the ability to easily implement Kelvin source connections. This separate low-inductance Kelvin source pin helps accurately sense the MOSFET’s source voltage, allowing better control of gate drive signals. For high-voltage power electronics working at fast switching speeds, this reduces unwanted oscillations and ringing caused by parasitic inductances in the source lead.

By minimizing switching transients with Kelvin source implementation, designers can lower electromagnetic interference (EMI) and improve overall system reliability. This makes discrete SiC MOSFETs ideal for applications like EV onboard chargers and solar PV inverters where clean switching edges and precise gate control are critical.

With modules, this sort of Kelvin connection is harder to separate at the device level, limiting fine gate-drive tuning. Discrete SiC devices, like those found in HIITIO’s range, give engineers the flexibility to optimize gate drivers for low switching loss and stable high-frequency operation.

For power solutions that demand this high level of control and efficiency, explore HIITIO’s selection of high-voltage SiC power modules and discrete MOSFETs designed for cutting-edge performance in demanding environments.

Key Application Sectors for HIITIO SiC Discrete MOSFETs: Electric Vehicles (EV) Onboard Chargers (OBC)

HIITIO SiC discrete MOSFETs are a game-changer for electric vehicle onboard chargers (OBC). Their wide bandgap technology means they handle high voltage efficiently while cutting down on switching losses, making EV charging faster and more reliable. With their low RDS(on) performance and superior thermal conductivity, these MOSFETs support higher power density designs without overheating, ideal for compact onboard charger systems.

The improved switching speed and reduced reverse recovery charge (Qrr) of HIITIO SiC devices allow for high-frequency operation, which boosts overall efficiency and helps shrink the size of EV OBC power supplies. This leads to smaller, lighter chargers that deliver power more cleanly—crucial for meeting the demanding thermal management and EMI mitigation standards in modern electric vehicles.

Additionally, discrete packaging like the TO-247 format offers design flexibility for automotive manufacturers, enabling easier integration and customization for specific EV models. This flexibility also supports better gate driver optimization and robust breakdown voltage stability, ensuring long-term reliability in harsh automotive environments.

For automotive power solutions that prioritize efficiency and durability, HIITIO’s SiC discrete MOSFETs deliver an edge, making them a top choice in the US EV market focused on next-generation high-voltage power electronics.

Learn more about additional high-voltage power modules like the 1200V 300A IGBT power module, which complements SiC technology in advanced powertrain systems.

Key Application Sectors for HIITIO SiC Discrete MOSFETs: Renewable Energy Solar PV Inverters

HIITIO SiC discrete MOSFETs are game changers for renewable energy, especially in solar PV inverters. Their wide bandgap technology delivers superior efficiency by reducing conduction and switching losses, which is critical for maximizing energy harvest from solar panels. The low RDS(on) and excellent thermal conductivity help maintain stable performance even under high voltage and temperature conditions common in outdoor solar setups.

These SiC MOSFETs enable higher switching frequencies, which shrink passive component size, boosting power density and overall system compactness. Plus, better reverse recovery characteristics reduce electromagnetic interference (EMI), ensuring cleaner power output and longer inverter lifespan. This means end users get a more reliable, efficient solar inverter that handles real-world demands better than traditional silicon devices.

For designers working on solar inverters, HIITIO’s TO-247 discrete package offers flexibility and ease of integration with optimized gate drive circuits, simplifying PCB layout and thermal management. With these benefits, HIITIO SiC MOSFETs are the go-to choice for next-gen solar PV inverter solutions driving America’s shift toward cleaner energy.

Check out HIITIO’s 1200V 800A SiC power module for more on their advanced SiC solutions ideal for renewable energy applications.

Key Application Sectors for HIITIO SiC Discrete MOSFETs: Renewable Energy Energy Storage Systems (ESS)

Energy Storage Systems (ESS) are critical for stabilizing and optimizing renewable energy sources like wind and solar. HIITIO SiC discrete MOSFETs bring clear advantages to ESS designs by offering exceptional wide bandgap semiconductor performance that directly impacts efficiency and reliability.

Thanks to their low RDS(on) performance and excellent thermal conductivity of SiC, these MOSFETs reduce conduction losses while managing heat better during high current operation. This results in lower junction-to-case thermal resistance, allowing ESS units to run cooler and more reliably under demanding conditions.

Additionally, HIITIO’s SiC MOSFETs minimize switching losses at high frequencies and exhibit superior reverse recovery characteristics, which improve the power density and operational efficiency of inverters and converters used in ESS. These benefits translate to smaller, lighter power electronics capable of handling the rigorous cycling typical of energy storage applications.

In short, integrating HIITIO SiC discrete MOSFETs in ESS helps maximize energy throughput, extend system life, and reduce overall operating costs. For renewable energy engineers looking to optimize solar or wind ESS, HIITIO’s portfolio offers a powerful solution grounded in high-voltage MOSFET reliability and performance.

Explore how HIITIO’s advanced SiC MOSFET power solutions are shaping the future of renewable energy storage with enhanced efficiency and thermal management.

Key Application Sectors for HIITIO SiC Discrete MOSFETs: Industrial Power Supplies, Server PSUs & Telecom Rectifiers

HIITIO SiC discrete MOSFETs are a game-changer in industrial power supplies, including server power supply units (PSUs) and telecom rectifiers. Their low RDS(on) performance and excellent thermal conductivity make them ideal for handling the demanding high-voltage, high-current conditions typical in these sectors.

In server PSUs, where efficiency and system reliability are critical, SiC MOSFETs help reduce conduction and switching losses, leading to improved power density and lower cooling requirements. This translates into quieter, more compact power supplies that are easier to integrate within data centers.

Telecom rectifiers demand stable breakdown voltage and superior reverse recovery characteristics—areas where HIITIO’s discrete SiC MOSFETs excel. The devices’ hard switching tolerance and low reverse recovery charge (Qrr) support better EMI mitigation and higher-frequency operation, which are crucial for telecom infrastructure resilience and efficiency.

Key benefits include:

- Enhanced power conversion efficiency to cut energy costs

- Improved junction-to-case thermal resistance for better heat dissipation

- Greater reliability under continuous high-voltage stress

For designers focusing on robust industrial power solutions, the discrete TO-247 package options offer flexibility and cost-effectiveness, supporting tailored system designs without the footprint constraints of larger modules. This is particularly beneficial for customized server PSU designs or telecom rectifier arrays requiring optimized thermal management.

Explore HIITIO’s range of power modules, such as their 1700V 600A chopper module, to see how their high-voltage products fit into demanding industrial power applications seamlessly.

In , HIITIO SiC discrete MOSFETs bring measurable performance and reliability gains to industrial power supplies, server PSUs, and telecom rectifiers—helping U.S. customers build more efficient, scalable, and durable power electronics systems.

Design Considerations for Integration: Gate Drive Requirements

When working with SiC discrete MOSFETs, proper gate drive design is key to unlocking their full potential in high-voltage power electronics. SiC MOSFETs require precise gate drive voltages and timings to optimize switching speeds and minimize losses.

Key Gate Drive Factors for SiC MOSFETs

| Aspect | Description | Impact |

|---|---|---|

| Gate Voltage Level | Typically 18–20 V for full enhancement | Ensures low RDS(on) and reliable switching |

| Gate Drive Current | High peak currents to quickly charge/discharge gate capacitance | Reduces switching losses and ringing |

| Turn-On/Turn-Off Speed | Fast switching to maximize efficiency but controlled to avoid EMI | Balances low switching losses and noise |

| Gate-Source Resistor | Adjustable resistor to tune switching speed | Helps mitigate voltage overshoot and oscillations |

| Kelvin Source Connection | Separate source terminal for gate drive return | Minimizes parasitic inductance and improves gate control |

SiC MOSFETs have lower gate charge compared to silicon devices, which means the gate driver can switch devices faster, reducing switching power losses significantly. However, faster switching also means higher risk of electromagnetic interference (EMI) if gate drive layout and parasitic inductances aren’t carefully managed.

Why Proper Gate Drive Matters

- Enhanced Switching Efficiency: Optimized gate drive voltage and current reduce switching losses in high-frequency operations.

- Improved Reliability: Correct gate voltages prevent device overstress and extend MOSFET lifespan.

- EMI Control: Proper turn-on/off timing and gate resistor tuning limit voltage spikes and ringing.

For designers in the U.S. market focusing on EV onboard chargers or solar PV inverters, gate drive optimization directly impacts system efficiency and compliance with EMI standards. Integrating HIITIO’s 1200V 32mΩ Silicon Carbide Power MOSFET TO-247 4L ensures compatibility with robust gate drivers engineered for SiC performance.

- Use 18–20 V gate drive voltage

- Enable high peak drive current for fast switching

- Employ gate-source resistors and Kelvin source connection

- Balance fast switching with EMI control

- Select compatible SiC MOSFET discrete packages like HIITIO TO-247 for efficient gate drive integration

Design Considerations for Integration: EMI Mitigation

When integrating SiC discrete MOSFETs into high-voltage power electronics, managing electromagnetic interference (EMI) is critical. The fast switching speeds of Silicon Carbide devices, combined with low RDS(on) and high-frequency operation, can increase the risk of EMI, potentially causing noise and signal integrity issues in sensitive circuits.

To mitigate EMI in your design, consider the following best practices:

- Optimize PCB Layout: Keep high-current loops short and minimize parasitic inductance to reduce voltage spikes.

- Use Proper Gate Driver Techniques: Employ gate driver optimization to control switching transitions and reduce overshoot and ringing.

- Implement Snubbers or Filters: RC snubber circuits or EMI filters can smooth switching edges and limit high-frequency noise.

- Shielding and Grounding: Ensure solid grounding and use shielding where necessary to contain radiated emissions.

- Package Choice: The TO-247 discrete package used in many SiC MOSFETs supports effective heat dissipation and helps maintain stable junction-to-case thermal resistance, which can also influence EMI behavior.

Balancing fast switching with careful EMI mitigation leads to better system reliability and performance. These strategies make integrating HIITIO SiC discrete MOSFETs ideal for reducing electromagnetic disturbances in demanding applications like EV onboard chargers and industrial power supplies. For designs requiring robust power modules with EMI considerations, you might also explore HIITIO’s 1200V IGBT power modules that complement SiC solutions in complex systems.

Design Considerations for Integration: Thermal Management

Effective thermal management is critical when integrating SiC discrete MOSFETs into high-voltage power electronics. Thanks to the superior thermal conductivity of SiC, devices can operate at higher junction temperatures while maintaining stability and performance. This means better heat dissipation and increased reliability compared to traditional silicon MOSFETs.

To optimize thermal performance:

- Use packages with low junction-to-case thermal resistance, like the popular TO-247 discrete package.

- Implement efficient heat sinks or cooling solutions to keep device temperatures within safe limits.

- Design PCB layouts that improve heat spread and reduce hotspots, ensuring consistent thermal conditions.

- Monitor temperature regularly during operation to prevent thermal runaway.

Proper thermal design not only keeps the SiC MOSFETs running cooler but also boosts system-level power density and overall efficiency—key advantages for demanding applications like EV onboard chargers and solar PV inverters. For robust power modules designed with these principles, check out HIITIO’s advanced 1200V 150A SiC power module, engineered for high thermal performance and reliability.

The HIITIO Difference: Reliability in High Voltage – Quality Assurance

When it comes to high-voltage power electronics, reliability is non-negotiable. HIITIO’s SiC discrete MOSFETs undergo rigorous quality assurance processes to ensure you get consistent, top-tier performance every time. This is essential for applications where system failure means costly downtime or safety risks.

Key Quality Assurance Highlights:

| Aspect | Details |

|---|---|

| Material Screening | Uses premium Silicon Carbide wafers for WBG performance and breakdown voltage stability. |

| Advanced Testing | Each device is tested thoroughly to meet strict RDS(on), switching loss, and thermal specs. |

| Robust Packaging | TO-247 and SOT-227 packages designed for minimal junction-to-case thermal resistance and mechanical stress. |

| Traceability | Comprehensive quality tracking backed by detailed device history and batch tracking. |

| Electrostatic Discharge (ESD) Protection | Devices go through ESD screening to maintain gate oxide integrity in harsh conditions. |

This commitment means HIITIO SiC MOSFETs support demanding high-voltage applications such as EV onboard chargers and industrial power supplies with confidence.

For a detailed look at HIITIO’s high voltage power modules and their robustness, check out the ED3 1200V 450A SiC power module, a great example of their quality-driven design.

With HIITIO, you get more than just a semiconductor—you get peace of mind that your high-voltage systems will operate reliably, efficiently, and safely.

The HIITIO Difference: Reliability in High Voltage – Portfolio Overview

HIITIO’s SiC discrete MOSFET portfolio offers a wide range of high-voltage, high-reliability devices tailored for demanding power electronics applications. Designed with advanced Wide Bandgap semiconductor technology, our lineup delivers low RDS(on), excellent thermal conductivity, and superior switching performance, making them ideal for sectors like EV onboard chargers, solar PV inverters, and industrial power supplies.

| Feature | Benefit | Application Focus |

|---|---|---|

| Voltage Ratings: 600V to 1200V | Supports varied high-voltage needs | EV DC-DC converters, telecom rectifiers |

| TO-247 Discrete Package | Easy integration, better heat dissipation | Server PSUs, energy storage systems (ESS) |

| Low RDS(on) Performance | Reduced conduction losses | Hard switching topologies in power supply designs |

| Optimized Gate Charge | Minimized switching losses | High-frequency switching power supplies (SMPS) |

| High Avalanche Rating | Robust short-circuit withstand | Industrial automation, robotics |

This comprehensive portfolio lets system designers pick the right SiC MOSFET for their specific voltage, current, and thermal requirements—ensuring optimized efficiency and long-term reliability. Our focus on discrete devices in common packages like TO-247 supports flexible PCB layouts and effective thermal management critical for high-power applications.

Explore how HIITIO’s 1200V 120A Silicon Carbide Schottky Diode complements our MOSFETs by enhancing reverse recovery characteristics in power conversion systems, boosting overall efficiency and reliability.

With HIITIO’s consistent supply chain and strict quality assurance, you get not only top-tier performance but confidence in every part. Our portfolio is engineered to support the rapid adoption of Silicon Carbide technology in the US power electronics market, helping your designs stay ahead.

The HIITIO Difference: Reliability in High Voltage..Supply Chain Stability

In the U.S. power electronics market, supply chain stability is more critical than ever. For HIITIO SiC discrete MOSFETs, consistent availability means engineers and manufacturers can confidently plan and scale projects without worrying about delays or shortages.

Key Elements of HIITIO’s Supply Chain Stability:

| Element | Benefit for High-Voltage Power Electronics |

|---|---|

| Long-term supplier agreements | Secures steady access to high-quality SiC wafers and materials |

| Localized manufacturing hubs | Reduces shipping times, ensuring faster delivery |

| Strict quality controls | Maintains breakdown voltage stability and device reliability |

| Efficient inventory management | Supports quick turnaround for TO-247 discrete packages |

These factors combine to offer reliable sourcing of HIITIO SiC discrete MOSFETs, reinforcing the overall system’s uptime and performance. This supply chain robustness aligns perfectly with demanding high-voltage applications—from EV onboard chargers to renewable energy inverters.

For end users designing next-generation power electronics, partnering with HIITIO means fewer interruptions and better project delivery. Learn more about our reliable solutions through the E2 1200V 100A SiC power module, showcasing HIITIO’s commitment to quality and availability.

This approach helps U.S.-based power electronics manufacturers and integrators reduce risks tied to component shortages, ensuring their designs using SiC MOSFETs maintain consistent performance and delivery schedules.