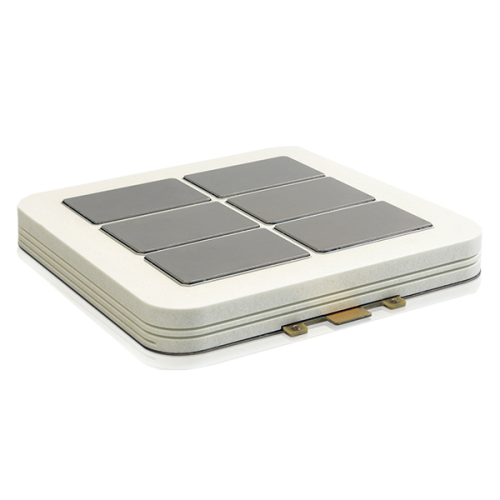

Press Pack IGBT

Revolutionary press-packed IGBT technology delivering unmatched power density, reliability, and thermal performance for demanding industrial applications.

Our Press Pack IGBT Projects in Operation

Zhangbei Flexible DC grid project

Voltage level: ±500kV

Power level: 3000MW

Converter station: Yanqing Converter Station

Dangxiong and Saga, Tibet Static Synchronous

Voltage level: AC 35kV

Power level: ±(50~150)Mvar

Converter station: Dangxiong and Saga Converter Station

Guangdong Central Channel Back-to-back flexible DC project

Voltage level: ±300kV

Power level: 2*1500MW

Converter station: Yuezhong Converter Station

Baihetan-Jiangsu UHVDC transmission project

Voltage level: ±800kV

Power level: 8000MW

Converter station: Gusu

Converter Station

Cutting-Edge Press Pack IGBT Innovation

Our press pack IGBT modules integrate state-of-the-art semiconductor technology with rugged mechanical engineering to deliver outstanding performance in demanding applications.

Exceptional Power Density

Ratings up to 6500V/3000A with optimized thermal management delivering maximum power output in a compact footprint.

Outstanding Reliability

Rugged press-pack construction guarantees excellent mechanical stability and long-term dependability even in harsh operating conditions.

Advanced Cooling Technology

Dual-sided cooling architecture with direct substrate contact achieving optimal thermal performance.

Seamless Integration

Standardized housing dimensions and connection interfaces enabling effortless system integration.

Why Partner with HIITIO

Partnering with HIITIO means choosing a collaborator committed to your success in press pack IGBT implementations. What distinguishes us is not only our technical expertise but our dedication to delivering genuine value:

Chip Technology Platform

Based on semiconductor industry evolution trends, we conduct research on chip technology generations to eliminate technical barriers for product development.

Packaging Technology Platform

Aligned with diverse application requirements, we manage product development through both performance and standardization pathways to enhance market competitiveness.

HIITIO implements holistic management practices as follows:

Product Development

We have integrated Huawei's IPD development methodology with APQP best practices into HIITIO's product development framework.

Incoming Material Quality Management

Equipped with advanced incoming inspection equipment primarily covering material properties of packaging raw materials.

Product Process Control

Utilizing advanced automated production lines and digital systems to achieve complete product traceability, conducting SPC, MSA, and abnormality alert management.

Supplier Quality Management

Supplier Quality Management Implementing rigorous supply chain management systems from initial stages through mass production, encompassing supplier research and quality incident resolution.

System Certifications

We maintain ISO 9001, IATF 16949, ISO 45001, and ISO 14001 certifications.

Manufacturing Capabilities

HIITIO Semiconductor’s IGBT packaging and testing facility represents a leading domestic fully automated, digitalized power module packaging and testing production line.

3100

Class 1000 clean room(㎡)

1000000

Annual production capacity of welded modules (units)

50000

Annual production capacity of press-fit modules(unit)

>98%

Yield rate of medium and low voltage products

- Capable of sealing and testing 650V-6500V IGBT modules.

- Equipment interconnection lines plus AGV enabling fully automated processing and material handling

- Comprehensive digital factory system architecture with real-time process information collection and analysis, big data-driven production decision-making

- 100% product inspection utilizing online X-ray and AOI

- Statistical Process Control (SPC) for real-time product characteristic monitoring

- 100% factory burn-in testing with PAT analysis of test data

Application Testing Expertise

HIITIO semiconductor power device laboratory spans 2,930 square meters with cumulative investment exceeding 100 million yuan. It encompasses reliability assessment, failure analysis, and testing capabilities, covering comprehensive certification capabilities from 650V to 6500V power devices. Achieved national CNAS certification in 2023.

Reliability Assessment

Environmental testing, high and low temperature storage, temperature and humidity fluctuations, temperature cycling, thermal shock, salt spray testing, vibration testing

Performance Evaluation

Static parameter testing, dynamic parameter testing, thermal resistance testing, temperature rise testing, ultimate capacity testing, surge testing, RBSOA testing

Application Evaluation

Two-level test evaluation system, three-level test evaluation system, reactive power aging test system, motor application test system, three-to-three disconnection test platform

Failure Analysis

X-ray fluoroscopy, acoustic scanning, metallographic microscopy, infrared thermal imaging, hotspot localization, scanning electron microscopy, parallel short circuit testing

Application of HIITIO PressPack IGBT

Long-Distance Ultra-High Voltage DC Transmission

Offshore Wind Power Flexible DC Transmission

Regional Grid Flexible DC Interconnection

Grid Active Support Capability Enhancement

Upgrade to Press Pack IGBTs for Superior Performance!

Power your systems with HIITIO Press Pack IGBTs, engineered specifically for high-power and high-voltage applications. Perfectly suited for HVDC, renewable energy, and industrial drives, HIITIO delivers the durability, redundancy, and performance you can depend on.

Get Datasheet Instantly

24/7 Fast Response

20 Years of Expertise

Tailored Solutions for Your Needs

Get A Free Quote

- We will contact you within 24 hours

- Don’t worry, we hate spam too!

Powered by HIITIO | Privacy Policy | Cookie Policy