What OEM Buyers Must Ask Before Choosing Power Module Suppliers

Discover essential questions OEM buyers must ask power module suppliers to ensure reliability, optimize total cost of ownership, and secure supply chain stability.

The Engineering Interrogation: Technical Fit

When specifying a power module supplier, the first critical step is assessing technical fit. OEM buyers often ask:

- How deeply do you support system-level design considerations?A reliable power module supplier goes beyond just delivering components. They collaborate on power module integration and system efficiency optimization, helping optimize thermal and electrical design tailored to your industrial power applications. Effective support includes guidance on high-voltage system design, electrical isolation and safety, and power density optimization to ensure your system meets performance and reliability goals.

- What is your approach to customization vs. off-the-shelf solutions?Choosing between a standard product and a tailored module can significantly impact your total cost of ownership (TCO) and system robustness. Suppliers should clearly outline:

| Aspect | Off-the-Shelf Modules | Customized Solutions |

|---|---|---|

| Delivery Speed | Faster, readily available | Longer lead times due to design and testing |

| Cost | Lower upfront cost | Potentially higher initial cost |

| System-Level Fit | Moderate, general-purpose | Optimized for specific applications |

| Reliability & Testing | Standard reliability validation | Enhanced reliability validation with tailored failure mode analysis (FMEA) |

| Long-Term Support | Baseline technical support | Dedicated engineering support and integration assistance |

A capable supplier like HIITIO emphasizes design for reliability and partners closely to decide when customization provides tangible benefits versus when off-the-shelf modules meet your power semiconductor solutions needs.

By digging into these engineering aspects upfront, OEM buyers ensure their chosen power modules align perfectly with system requirements, supporting long-term system robustness and optimized lifecycle costs.

The Reliability Stress Test (Quality Assurance)

When specifying a power module supplier, it’s crucial to understand how they handle reliability validation and failure mode analysis (FMEA). Ask your potential supplier to walk you through their reliability validation process, including the tests they run to ensure long-term stability under real industrial power applications.

Key points to consider:

- Thermal cycling performance: Does the supplier test modules under repeated temperature changes to prevent thermal fatigue?

- Failure mode analysis: How do they identify and mitigate common failure pathways in high-power semiconductor modules?

- Design for reliability: Are their power module designs optimized to reduce risk, improve system robustness, and support lifecycle performance evaluation?

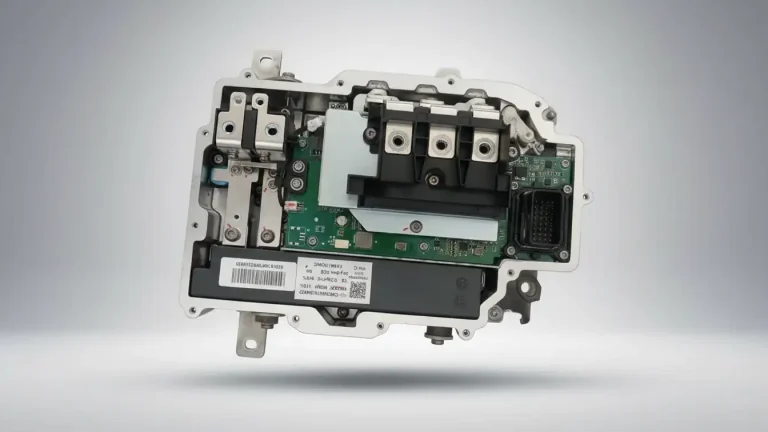

A thorough reliability validation process with a strong focus on FMEA and thermal testing reflects a supplier’s commitment to quality assurance and can help reduce unexpected downtime and maintenance costs. For example, advanced power modules like the 4500V 1200A high-voltage IGBT power module often undergo rigorous stress tests to guarantee durable operation in demanding conditions.

This reliability focus not only secures your product’s operational integrity but also plays into your system-level cost optimization by minimizing lifecycle risks and supporting a lower total cost of ownership (TCO).

The Commercial & Supply Chain Audit (Business Stability)

When evaluating a power module supplier, understanding the total cost of ownership (TCO) is crucial. It’s not just about the upfront price; you need to consider lifecycle cost analysis, including maintenance, potential downtime, and replacement expenses. A supplier who helps optimize system-level cost by offering durable power semiconductor solutions can reduce hidden engineering costs and improve your OEM sourcing strategy.

Long-term supply capability is another vital factor. You want a partner who guarantees consistent production of high-power semiconductor modules, ensuring supply chain resilience even during market fluctuations. Steady supply keeps your industrial power applications running smoothly without costly interruptions. Ask suppliers about their Quality Management System (QMS) and how they maintain production consistency at scale.

One example of a reliable option is their 1200V 900A IGBT power module, designed for robust thermal and electrical performance, which supports both reliability and cost efficiency for demanding power electronics systems.

The Compliance & Future-Proofing Check

When specifying a power module supplier, understanding their approach to compliance and certification is crucial. Power semiconductor solutions, especially for industrial power applications, must meet strict regulatory standards to ensure safety and reliability. Ask potential suppliers how they handle compliance with industry certifications and regulatory bodies. Do they maintain a robust Quality Management System (QMS) that supports ongoing compliance as standards evolve? This helps future-proof your design against changing requirements, reducing costly redesigns down the line.

Equally important is assessing their engineering support capability. A supplier who offers responsive, knowledgeable engineering assistance can help optimize power module integration and address system-level design considerations efficiently. From design for reliability to thermal and electrical design guidance, strong engineering support shortens development cycles and enhances system robustness. When combined with thorough compliance management, this level of support strengthens your OEM sourcing strategy, ensuring you receive not just a component, but a dependable partner in your power electronics systems.

For example, suppliers providing advanced high-power semiconductor modules like our 1200V 450A IGBT power module often back their products with comprehensive certification and ongoing engineering consultation — key for sustained long-term reliability. This holistic approach ultimately drives down your total cost of ownership (TCO) while reinforcing supply chain resilience.