What Is a Power Semiconductor Device Explained with Types and Uses

Discover what a power semiconductor device is its types features and key applications in EVs renewables with insights from HIITIO experts

Defining Power Semiconductor Devices, Core Structure, and How They Work

Power semiconductor devices are the backbone of power electronics components. Simply put, they control and convert electrical energy efficiently in everything from household gadgets to electric vehicles. At their core, these devices are made of semiconductor materials like silicon or silicon carbide, which can switch electrical currents on or off or regulate their flow.

The basic structure usually involves layers of semiconductor material arranged in a way that allows control over high voltage and current. For instance, power diodes have a simple two-layer design that lets current flow in one direction — acting like an electronic one-way valve. On the other hand, controlled devices like transistors and thyristors include extra layers or gates that let us turn the current on or off precisely.

Here’s how they work in simple terms:

- Switching: They can rapidly switch electrical current on and off to control power flow.

- Amplifying: Devices like transistors can boost a small electrical signal into a much larger current.

- Rectifying: Semiconductors like diodes convert AC (alternating current) into DC (direct current), which is essential in power supplies.

With these capabilities, power semiconductors handle high voltage and current levels while generating minimal heat and losses, making them key for efficient power conversion and management in many applications. Understanding this core helps us see why choosing the right semiconductor device is critical for performance and reliability in any power electronics system.

The Fundamentals Defining Power Semiconductor Devices Historical Evolution From Silicon to Next Gen Materials

Power semiconductor devices started mostly with silicon, the reliable workhorse of the electronics world. Silicon-based components like power diodes and IGBTs have been the backbone of power electronics for decades. They handle high voltages and currents efficiently, which made them ideal for applications in everything from industrial motors to household appliances.

But as demands grew for better performance, especially in electric vehicles (EVs) and renewable energy systems, silicon began to show its limits. That’s where next-generation materials like silicon carbide (SiC) and gallium nitride (GaN) come in. These wide bandgap semiconductors handle higher voltages, switch faster, and run cooler. For example, SiC MOSFETs and silicon carbide diodes are gaining ground for their superior thermal management and efficiency, crucial for EV power conversion and solar inverters.

This shift from silicon to next-gen materials marks a big leap in power electronics. It enables more compact, efficient, and durable devices to meet the increasing energy demands in the U.S. and global markets. Plus, thanks to advancements by power module manufacturers in China and worldwide, these innovations are becoming more accessible and cost-effective for everyday and industrial uses.

Types of Power Semiconductor Devices:Uncontrolled Devices, Power Diodes, and Rectifiers

Uncontrolled power semiconductor devices are the simplest type used in power electronics components. These include power diodes and semiconductor rectifiers, which allow current to flow in only one direction without any external control. That means once they’re on, you can’t switch them off using a gate signal—they conduct whenever forward voltage is applied.

Power diodes and rectifiers are essential in converting AC to DC power, making them the backbone of many power supplies and converters. You’ll find them in everything from everyday electronics to industrial machines. For example, silicon carbide diodes are becoming popular because they handle high voltages and currents more efficiently while reducing energy losses compared to traditional silicon devices.

Because they lack switching control, uncontrolled devices are reliable, rugged, and handle large currents with minimal losses. However, for applications requiring precise control or switching, controlled devices like IGBTs or thyristors are better suited.

Key points about uncontrolled devices:

- Allow current flow in one direction only

- No gate or control terminal to turn off the device

- Commonly used in rectification and power conversion

- Silicon carbide diodes improve efficiency and thermal performance

- Ideal for simple, robust, and high-current applications

Uncontrolled power semiconductor devices remain fundamental in power electronics, especially as a cost-effective option for converting and controlling electrical power safely.

Types of Power Semiconductor Devices: Controlled Devices, Transistors, and Thyristors

Controlled power semiconductor devices allow precise management of electrical power by switching or amplifying signals. The main players here are transistors and thyristors, each serving key roles in power electronics components.

Transistors like IGBTs (Insulated Gate Bipolar Transistors) and MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) are the workhorses in many applications. IGBTs stand out in high voltage and high current uses, such as EV power conversion, thanks to their efficiency and fast switching speeds. MOSFETs, especially silicon carbide (SiC) MOSFETs, are gaining attention for their high switching speed and thermal advantages, making them essential in cutting-edge power module manufacturers’ products.

Thyristors, including SCRs (Silicon Controlled Rectifiers), are known for handling very high voltages and currents. They’re widely used in industrial motor drives and large-scale power control systems because they can stay on once triggered until the current drops. While slower to switch than transistors, thyristors are reliable in steady-state high-power applications.

Together, these controlled devices enable flexible, efficient, and reliable power control essential in everything from household appliances to industrial equipment and renewable energy systems.

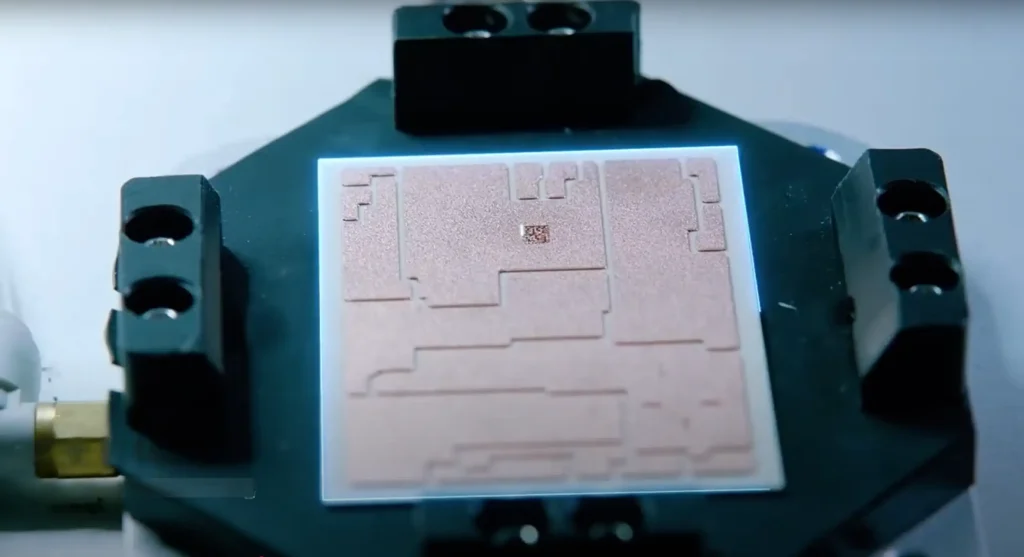

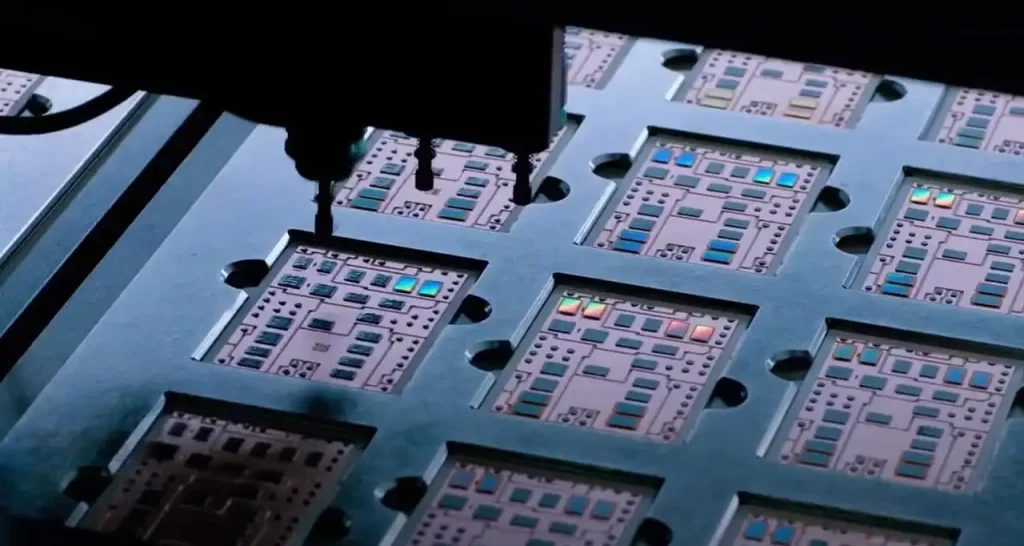

Types of Power Semiconductor Devices: Integrated Solutions Power Modules and ICs

Integrated power solutions like power modules and ICs are key players in simplifying and boosting power electronics systems. Power modules combine multiple power semiconductor devices—like IGBTs, MOSFETs, and diodes—into one compact unit. This integration improves performance, reduces losses, and makes cooling easier, which is crucial for applications demanding high efficiency and reliability.

Power ICs take integration further by combining control and power transistors in a single chip. These are widely used in smaller systems where space and power efficiency are critical, such as in EV power conversion and consumer electronics. They offer precise control, reduce external components, and simplify circuit design.

Benefits of integrated solutions include:

- Compact size and reduced system complexity

- Better thermal management due to optimized packaging

- Higher efficiency and reliability in power conversion

- Simplified assembly and lower production cost

For manufacturers and designers in the U.S. market, integrated power modules and ICs from trusted power module manufacturers China are becoming go-to options for upgrading power electronics in everything from industrial equipment to renewable energy systems. They are especially popular in high-growth sectors like electric vehicles and solar inverters, where performance and durability are top priorities.

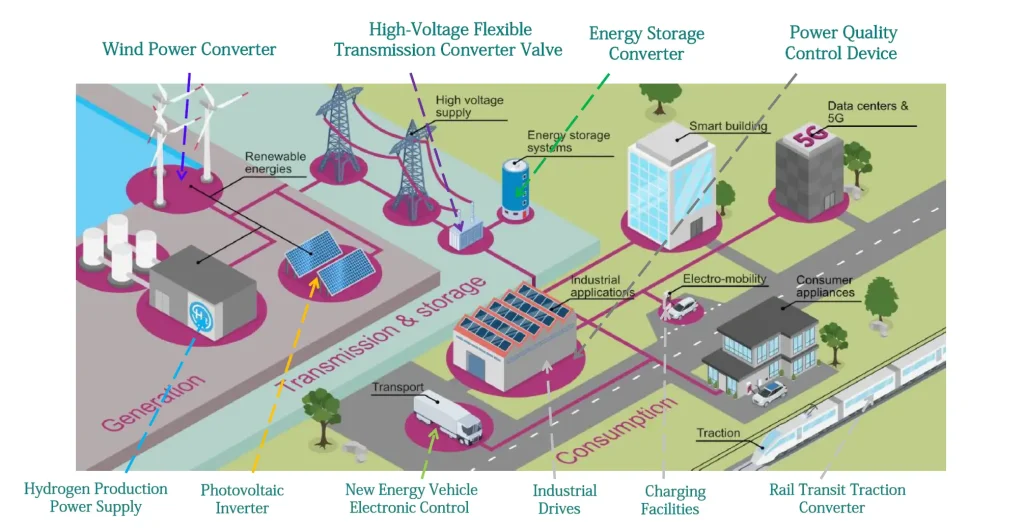

Key Applications Where Power Semiconductors Shine Every Day and Industrial Uses

Power semiconductor devices are behind many of the everyday gadgets and heavy-duty industrial machines we rely on. In homes, they control everything from the power supply in your laptop charger to efficient LED lighting and smart appliances. These devices manage power smoothly, ensuring your electronics run safely and efficiently.

On the industrial side, power semiconductors are essential in motor drives, factory automation, and power conversion systems. They help control high voltage and current in equipment like welding machines, elevators, and HVAC systems. This reliable control improves performance and cuts down energy waste, which is key for industrial users looking to save on costs.

Whether it’s keeping your smartphone charged or making heavy machinery run smoothly, power semiconductor devices play a critical role in keeping power electronics components efficient and reliable across various applications.

Challenges and Innovations in Power Semiconductor Technology

When it comes to power semiconductor devices, two major challenges stand out: thermal management and efficiency. These components handle high voltages and currents, which generate heat. If this heat isn’t managed properly, it can reduce device lifespan, cause failures, or even damage the entire system. For customers in the U.S., especially those working with EV power conversion or industrial power electronics components, reliable thermal management is critical.

Here are the key hurdles:

- Heat Dissipation: Power devices like high-voltage transistors and silicon carbide diodes generate a lot of heat during operation. Efficient cooling methods like heat sinks, liquid cooling, or advanced thermal interface materials are essential.

- Energy Losses: Every time a power semiconductor switches or conducts, some energy is lost as heat. Improving efficiency means reducing these conduction and switching losses without compromising performance.

- Material Limits: Traditional silicon semiconductor devices face limits in how much heat they can tolerate before efficiency drops. This is why many manufacturers are now shifting to wide bandgap semiconductors like SiC MOSFETs that handle higher temperatures better.

- Compact Designs: Modern applications demand smaller power modules and ICs. This puts extra pressure on thermal design because less space means less room for heat to escape.

Innovation in this area focuses on:

- Better materials that conduct heat more effectively.

- New packaging techniques improving heat flow away from chips.

- Improved device designs that operate cooler and deliver higher efficiency.

By tackling these hurdles, power semiconductor manufacturers in the U.S. and globally can deliver more reliable, efficient products, especially for fast-growing sectors like electric vehicles and renewable energy systems.

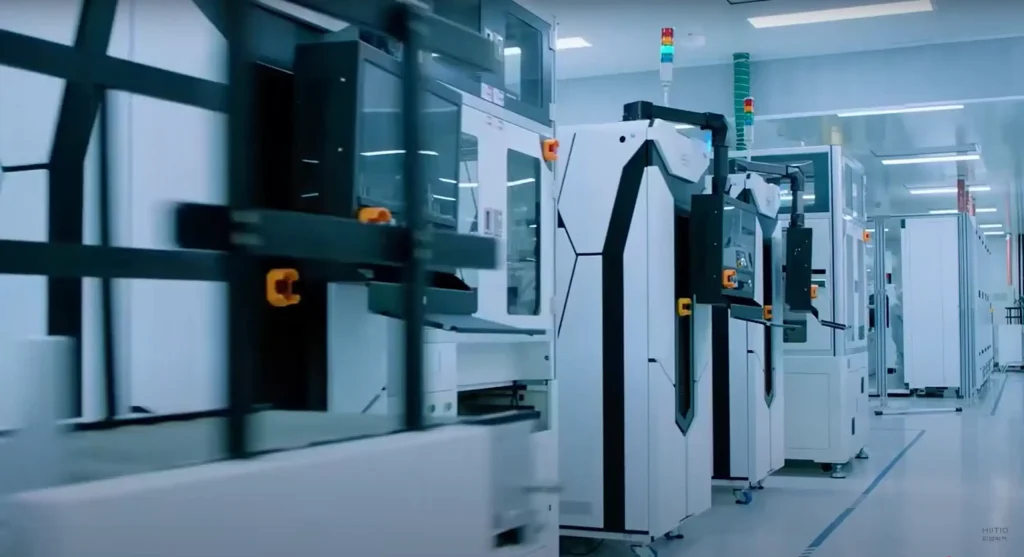

Why Choose HIITIO

When it comes to power semiconductor devices, HIITIO stands out as a leading power module manufacturer in China, known for reliability and advanced technology. We focus on delivering components that meet the unique demands of the U.S. market, from everyday power electronics components to cutting-edge EV power conversion solutions.

What We Bring to the Table

- Wide Product Range

We offer high voltage transistors, SiC MOSFETs, IGBTs, and silicon carbide diodes — all designed for efficient power management and thermal stability. - Advanced Technology

Our power modules and semiconductor rectifiers leverage wide bandgap semiconductors, enhancing efficiency and durability. - Customization

Solutions tailored to fit diverse applications, from industrial equipment to fast-growing renewable energy systems.

Why HIITIO Fits Your Needs

| Feature | Benefit for U.S. Customers |

|---|---|

| High-quality power modules | Reliable performance in harsh environments |

| Thermal management tech | Keeps devices cool, prolonging lifespan |

| SiC MOSFET and IGBT options | Ideal for electric vehicle and solar markets |

| Competitive pricing | Great value without cutting corners |

| Local support & logistics | Faster delivery and help when you need it |

By choosing HIITIO, you’re getting a partner who understands the power semiconductor market inside out—from components to integrated solutions. We help U.S. customers stay ahead in the race for better, more efficient power electronics.

Why Choose HIITIO China’s Powerhouse in Semiconductor Innovation

HIITIO stands out as a top power module manufacturer in China, delivering reliable power semiconductor solutions trusted by many US customers. Here’s a quick look at what makes HIITIO a go-to partner:

| Project Type | Challenge | HIITIO Solution | Result |

|---|---|---|---|

| EV Power Conversion | High efficiency needed | SiC MOSFET-based power modules | Improved range and reliability |

| Industrial Automation | Thermal management issues | Customized thermal design | Reduced overheating, longer device life |

| Renewable Energy Systems | High voltage and durability demands | IGBT and silicon carbide diodes | Higher performance and uptime |

These cases show HIITIO’s ability to tackle challenges in thermal management, efficiency, and device durability—key factors in power electronics components. Their advanced wide bandgap semiconductors and integration know-how support sectors from electric vehicles to renewables.

With HIITIO, you gain access to cutting-edge technology combined with proven manufacturing expertise. This helps businesses in the US scale up with solutions that are dependable, efficient, and designed to meet local market demands.