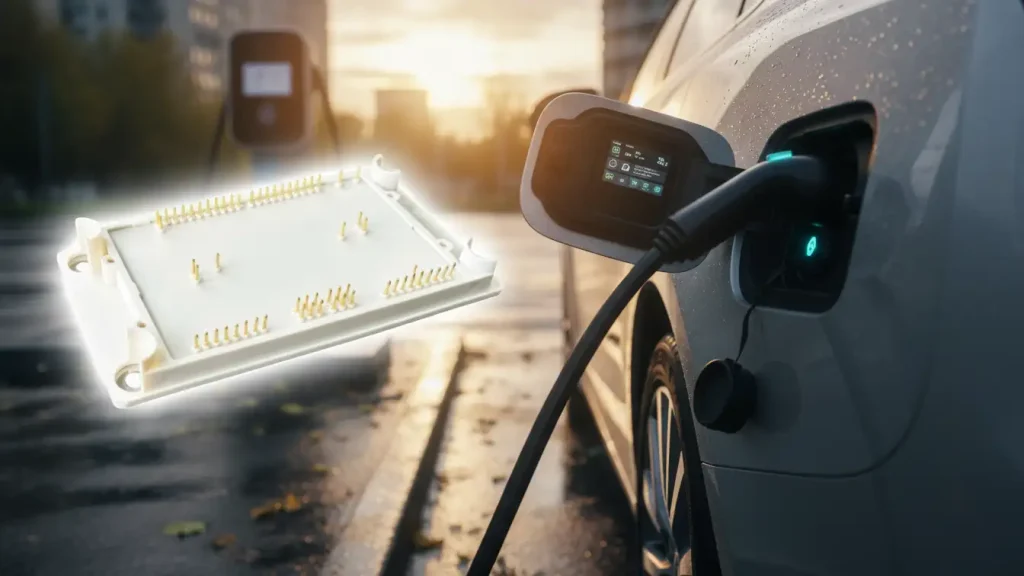

SiC Power Modules in EVs for Efficiency Range and Fast Charging

Explore the applications of SiC power modules in EVs driving efficiency with higher power density faster charging and extended battery range

What Are SiC Power Modules?

Silicon carbide (SiC) power modules are advanced semiconductor components designed to handle high power and voltage while improving efficiency in electric vehicles (EVs). What makes SiC unique is its wide bandgap—a property that allows these devices to operate at higher voltages and temperatures than traditional silicon counterparts. This wide bandgap means SiC modules can sustain high breakdown voltages, making them perfect for demanding automotive power electronics. Plus, SiC has superior thermal conductivity, helping these modules dissipate heat more effectively and maintain reliable performance under heavy loads.

Structurally, SiC power modules typically combine SiC MOSFETs and diodes within a single package. This integration not only reduces electrical losses but also simplifies system design by cutting down on external components. The packaging itself is engineered to handle harsh automotive environments, ensuring durability and safety in EV powertrains.

Over the years, SiC technology has evolved from using discrete devices—individual transistors and diodes—to fully integrated modules optimized for automotive applications. This shift allows car manufacturers to benefit from compact, efficient, and reliable systems tailored for high-voltage EV traction inverters, onboard chargers, and other critical components. The result? Higher power density, better thermal management, and improved overall vehicle efficiency.

Core Advantages of SiC Power Modules in EVs

Silicon carbide (SiC) power modules bring several key benefits to electric vehicles that help boost overall performance and efficiency. One major advantage is their ability to reduce switching and conduction losses, which means less wasted energy and higher system efficiency. This efficiency gain translates directly into longer battery life and better driving range.

Another significant edge is the increased power density of SiC modules. Because they handle more power in a smaller space, EV manufacturers can design compact, lightweight powertrains that save weight and room—critical factors for improving vehicle agility and efficiency.

SiC devices also excel in thermal performance, operating reliably at high temperatures without bulky cooling systems. This not only simplifies EV thermal management but also improves durability under demanding conditions.

Additionally, SiC modules support superior high-voltage handling and faster switching speeds compared to traditional silicon IGBTs. This makes them ideal for the latest EV architectures that run on 400V and even 800V systems, enabling smoother power delivery and quicker response times for motor control.

All these factors combined lead to tangible improvements in EVs, such as extended driving range, lower energy consumption, and enhanced overall vehicle performance. For anyone looking to get the most out of their EV, SiC power modules represent a crucial leap forward in power electronics.

For a deeper dive on how efficient power electronics improve battery performance, see how advanced integration enhances EV battery pack standards and driving safety in modern vehicles.

Key Applications of SiC Power Modules in Electric Vehicle Systems

Silicon carbide (SiC) power modules play a crucial role across multiple electric vehicle (EV) systems, boosting overall performance and efficiency.

Traction Inverters:

SiC power modules efficiently convert DC from the battery to AC for the motor drive. Their reduced switching losses and faster switching speeds improve power delivery and help increase the driving range while enabling more compact inverter designs.

Onboard Chargers (OBC):

In EVs, onboard chargers equipped with SiC devices enable quicker, more efficient AC-to-DC conversion. This speeds up charging times and reduces energy waste, making SiC onboard chargers a key component in modern EV charging solutions.

DC-DC Converters:

SiC-based DC-DC converters manage voltage regulation between the high-voltage battery and lower-voltage auxiliary systems. Their high efficiency reduces power losses, supporting systems like lighting, infotainment, and control units more reliably.

Auxiliary Power Systems:

SiC power modules provide power for auxiliary components like e-compressors for HVAC and thermal management systems. Their ability to operate at high temperatures and voltages ensures consistent performance under diverse driving conditions.

Off-board Fast Charging Infrastructure:

Beyond the vehicle, SiC modules are vital in high-power DC fast chargers. Their superior thermal performance and high-voltage handling help deliver fast, efficient charging, which is essential for the expanding US fast charging network.

These applications highlight how SiC power modules enhance various EV components, helping optimize powertrain efficiency and support faster, smarter charging solutions. For deeper insight into optimizing EV battery performance, you can explore our detailed electric battery pack guide.

SiC vs. Traditional Silicon IGBT Modules

When comparing SiC power modules to traditional silicon IGBT modules, the differences in performance are clear. SiC devices offer significantly higher efficiency thanks to lower switching losses and reduced conduction losses. This means better overall energy management and less wasted power in electric vehicle systems. SiC modules also handle higher switching frequencies, which helps improve powertrain responsiveness and reduces the size of passive components like inductors.

In terms of thermal performance, SiC power modules stand out by tolerating much higher temperatures. This reduces cooling needs and improves reliability under demanding operating conditions, allowing for smaller, lighter cooling systems. As a result, EV designs can be more compact and cost-effective.

Cost is always a factor. While SiC modules currently carry a higher upfront price than silicon IGBT modules, they enable total system-level savings. These savings come from smaller cooling systems, lower battery requirements due to efficiency gains, and longer component lifetimes. Real-world tests in EV platforms confirm that SiC-based traction inverters and converters deliver better efficiency and extend driving range, making the initial investment worthwhile over time.

For those looking to understand the impact of high-voltage EV architectures on system costs and efficiency, exploring comparisons between 400V vs. 800V EV battery pack platforms provides useful insights into why SiC modules are a preferred choice in next-gen electric vehicles.

Real-World Impact and Adoption Trends

Silicon carbide (SiC) power modules are making a solid mark in today’s electric vehicles. Leading automakers are integrating SiC-based components into both premium and mainstream EVs, particularly those adopting 800V architectures for faster power delivery and better efficiency. This shift is clear in models aiming to boost performance while cutting energy waste.

Benefits Realized with SiC Power Modules:

- Extended Driving Range: Lower switching and conduction losses mean more efficient energy use, helping vehicles go farther on a single charge.

- Reduced Charging Times: Faster switching speeds support higher voltage levels, enabling quicker onboard charging and compatibility with emerging fast charging stations.

- Improved Thermal Management: SiC’s superior thermal performance allows for smaller cooling systems, making EV designs more compact and reducing weight.

Adoption Snapshot

| EV Segment | SiC Adoption Level | Key Benefits |

|---|---|---|

| Premium EVs | High (800V + architectures) | Performance boost, range extension |

| Mainstream Models | Growing | Balanced cost-efficiency, shorter charging |

| Mid-Range & Compact | Early stage, rising | Cost-driven adoption, improved power density |

As the technology matures, more mid-range and compact EVs are adopting SiC power modules, driven by falling costs and system-level savings from lightweight battery packs and simplified cooling requirements. For deeper insight into efficient battery setups supporting these advances, check out this detailed guide on modular vs integrated EV battery packs.

The market outlook shows steady growth, with SiC expected to become a staple in automotive power electronics, helping vehicles achieve better electric vehicle efficiency and overall performance across all segments.

Challenges and Future Developments

Despite the clear benefits of SiC power modules in EVs, a few challenges still slow down their widespread adoption. The biggest hurdles right now are the higher cost of silicon carbide MOSFETs compared to traditional silicon devices, the relative immaturity of the supply chain, and packaging reliability issues. These factors can make integrating SiC power electronics into electric vehicles more complex and expensive upfront.

That said, the future looks promising. Next-generation SiC devices are being developed with better performance and lower costs. Improved module designs are addressing thermal management and reliability, while integration with 800V+ EV architectures is becoming more common. These advances help unlock even higher power density, faster switching speeds, and better high-voltage tolerance for next-gen EV powertrains.

As these innovations mature, we expect SiC power modules to gain broader adoption—not just in premium EVs but across mid-range and compact models as well. This shift will enable more efficient, lighter, and longer-range electric vehicles suitable for the wider U.S. market, driving further improvements in EV powertrain optimization and battery range extension.