SiC MOSFET vs Modules Guide When to Choose Discrete Devices

Explore when to choose discrete SiC MOSFETs or integrated SiC modules for optimal thermal management and power efficiency in high-power systems.

When designing power electronics, especially in high-voltage and high-frequency applications like EV traction inverters or solar inverters, choosing between discrete SiC MOSFETs and SiC power modules is critical. Each option offers unique advantages and constraints that affect switching speed, thermal management, parasitic inductance, and overall system efficiency.

Discrete SiC Devices

Discrete SiC MOSFETs are individual transistors packaged typically in TO-247, SOT-227, or compact DFN forms. These discrete devices offer:

- Flexible PCB layout options for power loop optimization and stray inductance minimization.

- Direct access to terminals enabling Kelvin source connection for precise gate drive and reduced switching loss.

- Easier integration for custom designs needing specific current ratings or voltages.

- Lower upfront component cost, benefiting cost-sensitive, low-volume production.

- The ability to manage thermal resistance at device level with external heatsinks or liquid cooling.

However, discrete MOSFETs require careful attention to PCB layout, assembly complexity, and effective heat dissipation to achieve optimal performance.

SiC Power Modules

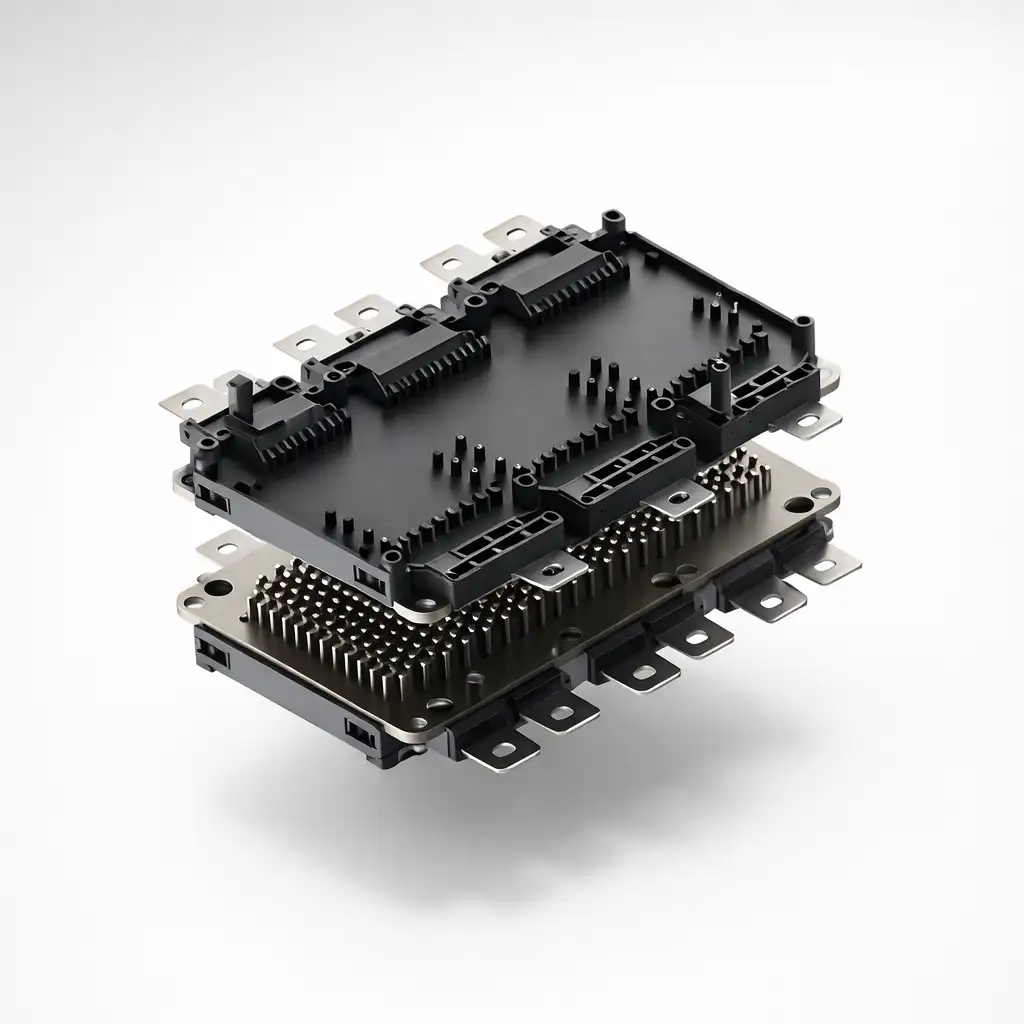

SiC power modules combine multiple discrete SiC MOSFETs and other components like diodes into a single high-power-density package. Their key features include:

- High-power density packaging that reduces overall system footprint.

- Embedded thermal interfaces to manage junction-to-case thermal impedance efficiently.

- Reduced parasitic inductance due to internal power loop optimization.

- Easier paralleling and reliable parallel current sharing between devices.

- Lower assembly complexity and improved reliability at high voltages due to factory-controlled manufacturing.

Modules shine in applications demanding high current capability, stringent space constraints, and consistent performance over time.

Choosing between discrete SiC devices and SiC power modules boils down to evaluating application requirements such as switching speed, thermal management, manufacturing volume, and total system cost. In the following sections, we’ll dive deeper into these critical factors to help guide your power electronics design decision.

Technical Deep Dive – The Critical Comparison Factors

When choosing between discrete SiC MOSFETs and SiC power modules, understanding key technical factors like parasitic inductance, thermal management, and current sharing is crucial. These elements directly impact system efficiency, reliability, and power density.

Parasitic Inductance and Switching Speed

- Discrete SiC Devices: Typically come in packages like TO‑247 or DFN, which can lead to higher stray inductance due to longer leads and PCB traces. This parasitic inductance slows switching speed and increases switching loss.

- SiC Power Modules: Designed with optimized power loop layouts to minimize parasitic inductance, enabling faster switching speeds and reduced switching losses. Kelvin source connection and internal busbars help lower switching noise and improve EMI performance.

| Feature | Discrete SiC MOSFET | SiC Power Module |

|---|---|---|

| Parasitic Inductance | Higher (long leads) | Lower (optimized layout) |

| Switching Speed | Moderate | Faster |

| Switching Loss Reduction | Limited | Enhanced |

Thermal Management and Heat Dissipation

- Discrete Devices: Have higher junction-to-case thermal impedance, which means heat removal depends heavily on the PCB design and external heat sinks. This can limit continuous current handling.

- SiC Modules: Use high-power density packaging that integrates advanced thermal interfaces to lower thermal resistance. This improves heat dissipation and ensures reliability at high junction temperatures.

| Thermal Attribute | Discrete SiC MOSFET | SiC Power Module |

|---|---|---|

| Junction-to-Case Thermal Impedance | Higher (depends on package) | Lower (integrated heat spreaders) |

| Heat Dissipation Efficiency | Moderate | High |

| Thermal Management Complexity | Higher (design-dependent) | Simplified (module optimized) |

Current Sharing and Paralleling

- Discrete Devices: Paralleling devices for higher current often requires careful PCB layout and matching of RDS(on) to prevent uneven current sharing, which complicates design.

- SiC Modules: Already optimized for parallel current sharing internally, reducing design complexity and improving reliability for high-current applications.

| Current Sharing Aspect | Discrete SiC MOSFET | SiC Power Module |

|---|---|---|

| Ease of Paralleling | Difficult (manual tuning) | Plug-and-play |

| Reliability at High Currents | Requires careful design | High due to internal balancing |

Understanding these factors helps choose the right solution, balancing switching performance, thermal behavior, and system complexity. For example, the HIITIO power modules offer advanced parasitic inductance minimization and thermal resistance control for efficient, high-reliability operation in automotive traction inverters and industrial power systems. You can explore solutions like the 1200V 600A Easy-3B IGBT Power Module for a practical example of module-level integration.

The Economic Reality – BOM Cost vs. System Cost

When comparing SiC MOSFET discrete devices to SiC power modules, it’s essential to look beyond just the component cost. While discrete SiC MOSFETs typically have a lower bill of materials (BOM) cost, the total system cost often tells a different story.

Component Cost

Discrete SiC MOSFETs in TO-247 or SOT-227 packages tend to cost less per device. However, building a complete power stage requires multiple MOSFETs alongside necessary gate drivers, PCBs designed for power loop optimization, and often additional cooling solutions. On the other hand, SiC power modules integrate several devices in a compact, high-power density package, which can raise upfront component expenses but reduce complexity and cost down the line.

Assembly and Manufacturing Cost

Discrete devices demand meticulous PCB layout for parasitic inductance minimization and careful thermal management to maximize efficiency and reliability. This typically increases assembly time and the need for skilled labor. Meanwhile, SiC modules—such as the ED3 1200V 900A SiC Power Module—offer standardized packaging with integrated heat spreaders and optimized internal connections like Kelvin source connections to help with switching loss reduction and thermal stability. This translates to lower assembly complexity and fewer chances for layout errors, saving on manufacturing costs and improving yield.

The Verdict

If your emphasis is purely on upfront BOM cost and you have a streamlined manufacturing process, discrete SiC devices may make sense. But for applications demanding reliability at high voltages, reduced junction-to-case thermal impedance, and streamlined assembly—especially for medium to high-power systems—SiC power modules often bring better value when considering the total system cost.

Ultimately, understanding your project’s power level, assembly capabilities, and long-term reliability needs will guide whether the lower component cost of discrete MOSFETs outweighs the broader benefits of SiC modules.

When to Choose Discrete SiC Devices

Discrete SiC MOSFETs are often the go-to choice for specific scenarios where their unique strengths shine. Here’s when you should consider them:

Low Power Applications

For systems under moderate power levels—think under 30kW—discrete SiC devices offer a simpler, cost-effective solution. Their easy integration and flexibility in packaging fit well with less demanding thermal management needs and lower current ratings.

Cost-Sensitive, Low-Volume Production

If you’re working on a budget or a project with limited production runs, discrete devices help reduce the Bill of Materials (BOM) cost. They eliminate the need for expensive module housings and complex assembly, keeping your total system cost manageable without sacrificing reliability.

Design Flexibility

Discrete packages like TO-247 or SOT-227 allow engineers to optimize PCB layout for stray inductance minimization and power loop optimization. You can tailor the gate driver circuits, add Kelvin source connections for better switching loss reduction, and customize thermal interface materials—something not as easily done with fixed module designs.

| Benefits of Discrete SiC Devices | Details |

|---|---|

| Lower BOM cost | Eliminates module housing and assembly fees |

| Simpler assembly | Reduced assembly complexity and time |

| Better PCB layout control | Enables optimization for parasitic inductance |

| Easier thermal customization | Choose thermal interface materials for junction-to-case thermal impedance |

| Ideal for low power & prototyping | Easy to scale without overdesign |

For reliable discrete SiC MOSFET options, check out the 1200V 40mΩ Silicon Carbide Power MOSFET TO-247 from HIITIO.

In short, if your design is cost-sensitive or requires versatile layout and thermal solutions at lower power levels, discrete SiC devices usually offer the best balance of price and performance.

When to Choose SiC Modules (The HIITIO Solution)

Choosing between discrete SiC MOSFETs and SiC power modules depends heavily on your project needs. SiC modules, like those from HIITIO, shine when high power density, reliability, and space savings are top priorities.

Why SiC Modules?

| Factor | Why Choose SiC Modules |

|---|---|

| High Power Density | Modules offer compact, high-power packaging that optimizes power loop and minimizes stray inductance—critical for automotive traction inverters and industrial drives. |

| Reliability Focus | Integrated designs reduce assembly complexity and improve junction-to-case thermal impedance, boosting system durability especially in harsh environments. |

| Space Constraints | When PCB real estate is limited, modules provide a neat high-power solution, helping achieve system miniaturization without sacrificing performance. |

HIITIO’s SiC power modules specifically address these needs with advanced packaging that cuts parasitic inductance and improves PCB layout parasitics, enabling faster switching speeds and lower switching losses. The modules come equipped with features like Kelvin source connections and optimized thermal resistance, ensuring smooth current sharing and effective heat dissipation.

For high-reliability applications requiring high-voltage Wide Bandgap integration, you can explore HIITIO’s 1200V 150A SiC power module designed precisely for high-efficiency power electronics.

In :

- Go for SiC modules when system efficiency and space are critical.

- Choose modules to reduce total system cost by simplifying assembly.

- Rely on HIITIO’s power module solutions to meet demanding thermal and electrical challenges.

In the next section, we’ll look at real-world case studies that illustrate these choices in action.

Case Study Scenarios

Scenario A: A 22kW EV Charger

For a 22kW electric vehicle (EV) charger, choosing between discrete SiC MOSFETs and SiC power modules hinges on balancing cost and performance. Discrete devices often make sense here due to their low power requirements and the flexibility they offer in optimizing the PCB layout to reduce parasitic inductance. Using discrete SiC MOSFETs in TO-247 or DFN packages lets designers focus on switching loss reduction and power loop optimization without significantly driving up the assembly complexity or overall system cost. For a mid-level charger like this, discrete solutions allow customizing thermal management using standard heat sinks, and the junction-to-case thermal impedance remains manageable.

Scenario B: A 150kW Solar Inverter

When it comes to a 150kW solar inverter, the story shifts considerably. At this higher power level, SiC power modules excel with their high-power density packaging and integrated design that supports parallel current sharing more effectively. Modules minimize stray inductance and simplify PCB layout parasitics, which is critical for maintaining efficiency and reliability under heavy loads. Their robust thermal paths improve heat dissipation, vital for keeping the device within safe junction temperatures. The focus here is also on reliability at high voltages and stable operation across demanding conditions, making the integration of specialized solutions like the 1200V 300A IGBT power module or 1200V SiC power modules a smart fit. In this case, modules reduce total system cost analysis despite a higher upfront component cost, thanks to simplified assembly and enhanced system efficiency.

Both scenarios highlight the trade-offs between discrete and module options based on power level, thermal demands, switching speed, and cost — crucial factors when designing energy-efficient, reliable power electronics for the U.S. market.

Making the Future-Proof Decision

Choosing between SiC MOSFET discrete devices and SiC power modules boils down to your project’s long-term needs and priorities. If your design demands high-power density packaging with streamlined thermal management and minimal assembly complexity, modules like those offered by HIITIO provide a reliable, space-saving solution that helps reduce junction-to-case thermal impedance and optimize power loop efficiency. On the other hand, discrete SiC MOSFETs give you more control over PCB layout parasitics and stray inductance minimization, which is key for applications where switching speed and cost sensitivity are critical.

When planning for future upgrades or scalability, consider how easily your design supports parallel current sharing and heat dissipation—critical factors that impact both system reliability and efficiency. While discrete devices may suit low-volume, cost-conscious designs with flexible configurations, SiC power modules often deliver better performance in automotive traction inverters, EV chargers, and industrial power systems where robust reliability at high voltages is non-negotiable.

Taking a holistic view of your system, including total system cost analysis—not just the Bill of Materials (BOM)—will help you avoid costly redesigns down the line. Balancing upfront component costs against assembly, testing, and lifecycle durability benefits ensures a truly future-proof power electronics solution. To explore ready-made high-performance options, check out HIITIO’s 1700V 600A SiC Power Module and the compact 62mm 1700V 300A SiC Power Module for proven reliability in demanding applications.