Integration of Power Modules with Gate Drivers for Optimal Efficiency

Discover the benefits and challenges of integration of power modules with gate drivers for efficient high-frequency power electronics designs.

Power modules and gate drivers are key building blocks in modern power electronics systems. At their core, power modules house power switches, typically IGBTs (Insulated Gate Bipolar Transistors) or SiC MOSFETs (Silicon Carbide Metal-Oxide-Semiconductor Field-Effect Transistors). These switches control high currents and voltages efficiently, enabling applications like electric vehicle inverters and renewable energy inverters.

Meanwhile, gate drivers serve essential functions: they provide voltage amplification to properly turn the power switches on and off, offer galvanic isolation to protect low-voltage control logic from high voltage circuits, and implement protection features like under-voltage lockout (UVLO) and desaturation (DESAT) detection. These drivers ensure reliable and safe switching, minimizing switching loss and conduction loss.

Traditionally, power modules and gate drivers have been designed as separate components, connected via wiring or PCB traces. While this approach allows flexibility, it introduces parasitic inductance and increases electromagnetic interference (EMI), resulting in slower switching speeds and less efficient operation.

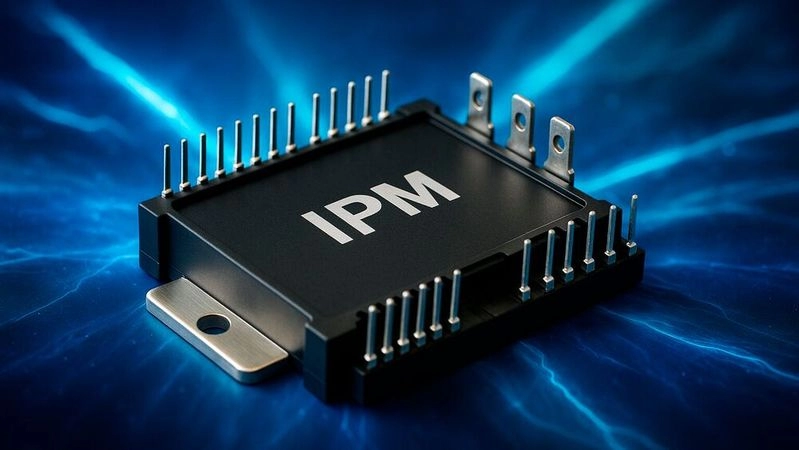

To overcome these issues, the industry is evolving toward module-level integration. This trend includes plug-and-play solutions where gate drivers are embedded directly within the power module or adapted to match specific module layouts. Integrated designs reduce parasitic inductance in gate loops and improve EMI mitigation, leading to better overall system performance. Some advanced modules even feature embedded intelligent power modules (IPMs), which combine power switches and gate drivers with built-in protection and diagnostic capabilities.

This shift toward integration is pivotal for meeting demands in high-frequency power electronics, automotive-qualified power modules, and high-voltage SiC modules, enabling compact, efficient, and reliable power systems for today’s energy and transportation sectors.

Key Benefits of Power Module Gate Driver Integration

Integrating power modules with gate drivers brings several clear advantages that boost overall system performance and cut costs. Here are the key benefits:

| Benefit | Impact |

|---|---|

| Reduced Parasitic Inductance | Minimizes inductance in gate loops, enabling faster and cleaner switching signals. |

| Lower Switching & Conduction Losses | Improves efficiency by reducing energy waste during device turn-on/off and conduction. |

| Improved EMI Performance | Less ringing and noise, leading to better electromagnetic interference (EMI) mitigation. |

| Enhanced Thermal Management | Better heat dissipation increases system reliability and device longevity. |

| Compact Design & Lower BOM | Fewer external parts shrink the size and reduce bill of materials (BOM) and assembly effort. |

| Advanced Protection Features | Built-in solutions like DESAT detection, undervoltage lockout (UVLO), and active clamping enhance device safety. |

These benefits make integrated gate driver modules ideal for demanding applications such as electric vehicle inverters and high-frequency industrial drives. For example, modules like the 1200V 450A IGBT power module with embedded gate drivers demonstrate the potential to streamline power electronics designs while boosting efficiency and reliability.

Integration helps reduce switching losses and conduction losses, directly driving higher power efficiency. Plus, with EMI improvements and thermal advantages, overall system performance is more stable, which is essential for automotive-qualified power electronics and renewable energy inverters alike.

Technical Challenges and Solutions in Power Module Gate Driver Integration

Integrating power modules with gate drivers comes with several technical hurdles, especially in high-voltage, high-frequency setups like electric vehicle inverters and industrial motor drives. Here’s a clear look at key challenges and solutions:

| Challenge | Solution Approach |

|---|---|

| High dv/dt & Common-Mode Transients | Use careful PCB layout to reduce parasitic inductance and shield sensitive signals; apply differential signaling and optimized gate driver circuits for better transient immunity. |

| Thermal Management in Co-Packaged Drivers | Employ advanced thermal interface materials and integrate heat sinks or cooling paths; proper thermal simulation guides placement of drivers near power switches without overheating. |

| Gate Voltage Optimization for SiC vs. IGBT | Tailor gate driver voltage levels—SiC MOSFETs typically need lower gate voltages but faster switching, while IGBTs benefit from higher drive voltages; adaptive driver control helps. |

| Isolation and Signal Integrity | Use galvanic isolation techniques like optocouplers or digital isolators with low propagation delay, maintaining clean signals while meeting safety standards. |

| Short-Circuit and Overcurrent Protection | Implement active clamping, DESAT detection, and undervoltage lockout (UVLO) circuits within integrated drivers to quickly protect devices without added external components. |

| Layout Best Practices | Design symmetrical layouts for parallel devices to ensure current sharing and reduce loop inductance; keep gate loops short and route return paths cautiously to minimize EMI. |

Addressing these challenges head-on allows integrated power module gate drivers to deliver improved efficiency and reliability, especially in demanding environments like automotive-qualified power modules such as the 1200V 600A Easy 3B IGBT Power Module F1.

By combining proper gate drive voltage control, effective thermal design, signal isolation, and protective features, modern integrated solutions offer a significant edge in switching loss reduction and EMI mitigation for high-frequency power electronics.

Application-Specific Integration Insights

When it comes to integrating power modules with gate drivers, the specific application really shapes the design and benefits. In electric vehicle (EV) inverters and traction systems, high voltage levels and strict automotive qualifications demand reliable, compact modules. Integrated solutions reduce gate driver parasitic inductance and boost switching speed, which is critical for meeting efficiency and durability standards in EV powertrains. For example, advanced automotive qualified power modules are engineered to operate seamlessly in harsh environments while optimizing conduction and switching losses.

Renewable energy inverters for solar and wind power systems also benefit hugely from gate driver integration. The reduced electromagnetic interference (EMI) and improved thermal management enable higher power density and longer service life. Charging infrastructures for EVs rely on these compact, efficient modules to handle high frequencies and support fast, reliable charging cycles.

Industrial motor drives demand robust operation at high frequencies too, and integrated intelligent power modules (IPMs) simplify system design by combining power switches, gate drivers, and protection features into one package. IPMs improve overall power efficiency and reduce the complexity of external components, lowering both BOM and assembly costs.

These examples clearly show how integrating power modules with gate drivers not only boosts efficiency and reliability but also drives size and cost reductions across different industries. The resulting higher power density and improved system performance are key factors for U.S. manufacturers focused on next-generation power electronics. For tougher applications, high voltage SiC modules like the L200V 13mΩ Silicon Carbide Power MOSFET TO-247-4L offer excellent switching loss reduction and thermal advantages tailored for demanding industrial and automotive environments.

Future Trends in Power Module and Gate Driver Integration

The future of power module gate driver integration is clearly leaning toward wider adoption of wide-bandgap semiconductors like SiC MOSFETs. These devices enable higher switching frequencies and can operate reliably at elevated temperatures, making them ideal for next-gen power electronics. With SiC technology, we see reduced switching and conduction losses, which directly boosts power efficiency in demanding applications such as electric vehicle inverter design and renewable energy inverters.

Advanced packaging techniques are another major trend. Embedding gate drivers directly within the power module or using heterogeneous integration allows for tighter coupling, reducing parasitic inductance and improving EMI mitigation. This not only enhances system reliability but also leads to more compact, plug-and-play solutions that simplify assembly and lower costs.

HIITIO is at the forefront of these innovations, offering high-voltage power modules that support integrated driver ecosystems optimized for automotive-qualified and industrial motor drive applications. Their 1700V 400A SiC power module is a good example, combining advanced SiC technology with integrated gate drivers for superior performance.

Looking ahead, the focus will also be on scalable, flexible modules tailored for high-frequency power electronics and sustainability goals. Expect continued improvements in thermal management, protection features, and intelligent power module (IPM) designs that will drive the next generation of efficient, reliable, and compact power solutions across automotive, renewable energy, and industrial sectors.