Innovative SiC MOSFETs Boost Efficiency in Industrial Automation

Explore innovative applications of SiC MOSFETs in industrial automation with HIITIO’s high-efficiency, high-reliability power modules and solutions.

Why Industrial Automation Demands SiC Technology

Industrial automation is evolving rapidly, driven by the need for higher efficiency, better reliability, and compact designs. Silicon Carbide (SiC) MOSFETs are at the heart of this shift, thanks to their wide bandgap semiconductor efficiency and superior electrical properties.

Breaking the Efficiency Barrier

SiC MOSFETs significantly reduce both conduction loss and switching loss, cutting operational expenses (OPEX) for factories and plants. Their inherently low RDS(on) means less energy wasted as heat, while fast switching capabilities improve power conversion efficiency. This helps:

- Lower energy bills through reduced power dissipation

- Enhance overall system performance

- Enable smarter, cost-effective automation solutions

Thermal Management & Reliability

SiC’s ability to operate at high junction temperatures translates into better thermal management. This advantage allows:

- Use of smaller heat sinks and fewer cooling fans

- More compact power modules with improved reliability

- Extended device lifetime critical for industrial environments

Power Density & Form Factor

Thanks to higher switching frequencies, SiC technology enables smaller passive components like inductors and capacitors. This reduction results in:

- Increased power density within servo drive inverter topologies and motor drives

- Compact, integrated solutions like Integrated Motor Drives (IMD)

- Streamlined form factors that fit the space constraints of modern industrial setups

SiC MOSFETs are transforming industrial automation, meeting the demands for high-voltage power modules that are both powerful and efficient, setting a new standard for smart manufacturing energy efficiency.

Innovative Application #1: High-Precision Servo Drives & Motion Control

Servo drives have been a cornerstone of industrial automation, but traditional designs often come with bulky inverter stages and extensive cabling that limits flexibility and takes up valuable floor space. This setup can lead to increased power losses and slower response times, making precision motion control more challenging and costly.

Enter Silicon Carbide (SiC) MOSFETs, which have revolutionized servo drive inverter topology. By enabling integrated motor drives, SiC technology significantly shrinks the size of inverter stages. These high-voltage MOSFETs support higher switching frequencies, which improves control bandwidth and allows for more accurate, responsive motion control. Plus, SiC’s low conduction and switching losses help reduce operational expenses by boosting overall efficiency.

A significant innovation in this space is regenerative braking using SiC topologies. This feature recovers energy normally wasted during deceleration and feeds it back to the system, enhancing energy efficiency and reducing heat generation. Combined with smaller, efficient power modules like the HIITIO 1700V 600A SiC power module, industrial servo drives become more compact, reliable, and energy-efficient—ideal for the fast-paced demands of modern manufacturing.

Key Benefits:

- Reduced system size and cabling complexity

- Enhanced motion control with high-frequency switching

- Lower conduction and switching losses cut energy costs

- Regenerative braking for energy savings and heat reduction

SiC MOSFETs are setting a new standard in servo drive inverter topology, enabling smarter, more precise motion control in today’s industrial automation.

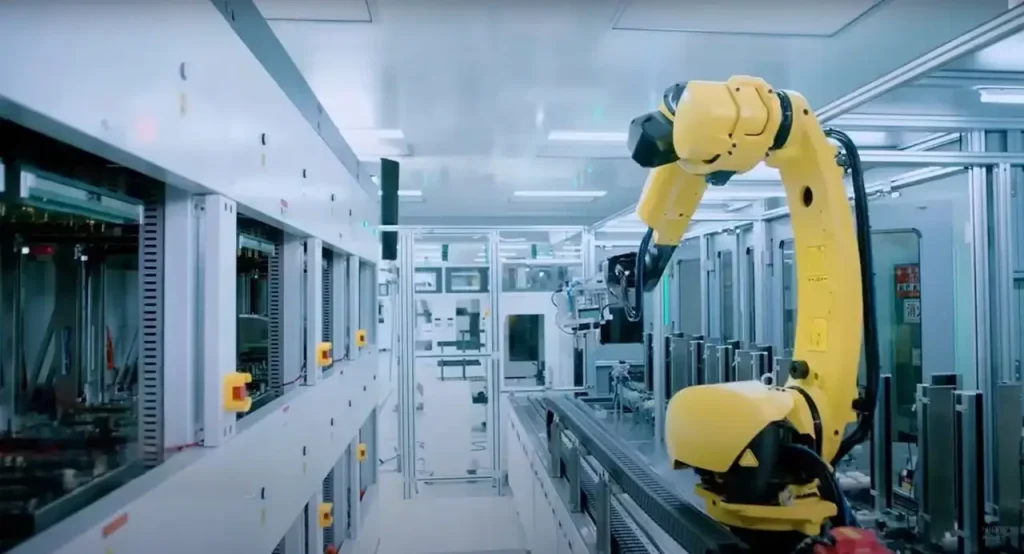

Innovative Application #2: Collaborative Robots (Cobots) & Industrial Robotics

In industrial robotics, especially with collaborative robots (cobots), the balance between weight and power is critical. Lightweight power electronics powered by Silicon Carbide (SiC) MOSFETs allow cobots to handle heavier payloads without sacrificing agility or precision. By reducing the size and weight of power modules, manufacturers can significantly boost the robot’s overall efficiency and flexibility on the factory floor.

SiC’s low conduction and switching losses contribute to low-loss power electronics that keep actuators cool, even during continuous operation. Discrete SiC transistors minimize heat generation, which means better thermal management and longer device lifetimes—key advantages for high-reliability industrial robotics applications.

For battery-powered mobile robots used in warehouses and logistics, SiC inverters deliver high efficiency that extends runtime and cuts down on charging frequency. This means longer operation cycles and less downtime, helping boost productivity and reduce operational costs. Solutions like the 1200V 40mΩ Silicon Carbide Power MOSFET in TO-247 packages make integrating these benefits into robotic power electronics simpler and more effective.

Overall, SiC technology is pushing industrial robotics toward lighter, more efficient, and longer-lasting power systems—a game changer for smart manufacturing in the United States.

Innovative Application #3: Industrial Power Supplies (SMPS) & UPS Systems

Silicon Carbide MOSFETs are transforming industrial power supplies and uninterruptible power supplies (UPS) by enabling next-generation SMPS designs that push efficiency to the coveted 80 Plus Titanium level. This means less wasted energy, lower operational costs, and reduced heat generation in critical industrial environments.

For UPS systems, SiC’s fast switching capabilities let manufacturers shrink the backup power footprint significantly. By reducing switching losses, these devices minimize the size of magnetics and EMI filters, making the whole system more compact and easier to integrate into tight spaces. This leads to improved power density and reliability—two must-haves in today’s demanding industrial automation setups.

Using high-voltage SiC MOSFETs also enhances thermal management, allowing for smaller heat sinks and simpler cooling systems, which is particularly important in continuous operation scenarios. Industrial companies looking for robust power modules can consider solutions like HIITIO’s 1700V silicon carbide Schottky diodes that support high-efficiency power conversion and thermal performance.

Overall, SiC-based power supplies and UPS units are setting a new standard for efficiency, reliability, and compactness in industrial automation applications.

Engineering Challenges and Design Considerations

Taming the Speed: Managing dv/dt and Parasitic Inductance in PCB Design

SiC MOSFETs excel with their fast switching capabilities, but that speed comes with design challenges. High dv/dt (voltage change rate) can cause unwanted voltage spikes and ringing due to parasitic inductance in the PCB layout. Careful PCB design is essential to minimize loop areas and stray inductance, ensuring stable operation and protecting components from potential damage. Optimized trace routing and low-inductance layouts help tame switching transients, a must-have for reliable wide bandgap semiconductor efficiency.

Gate Drive Circuitry: Choosing Proper Gate Driver ICs for Safety and Reliability

SiC MOSFETs require specialized gate driver ICs that match their fast switching traits and voltage requirements. Selecting the right gate driver ensures precise control, reduces switching losses, and boosts device lifespan. A gate driver with proper isolation, overcurrent protection, and optimized gate charge handling keeps the system safe and stable, preventing issues like shoot-through or false triggering common in high-voltage power modules.

EMI Mitigation: Handling Electromagnetic Interference from High-Frequency Switching

High-frequency switching in SiC MOSFETs can generate significant electromagnetic interference (EMI), which affects nearby electronics and system performance. Effective EMI mitigation involves shielding, careful component placement, and adding snubbers or filters to reduce noise. Balancing switching speed and EMI is critical, especially in industrial automation environments where multiple sensitive devices operate close together.

HIITIO’s Approach: Balancing Switching Speed, Thermal Performance, and Integration Ease

At HIITIO, we focus on optimizing this complex balance by developing power modules that combine fast switching with excellent thermal management and simplified integration. Our expertise in package design and gate driver compatibility results in solutions that reduce parasitic effects and facilitate EMI control. This approach not only ensures high reliability but also supports the shrinking form factor of next-generation industrial automation systems.

For those needing robust power modules designed for tough industrial conditions, our 1200V 450A IGBT power module demonstrates how advanced semiconductor technology can meet rigorous design challenges.

The Future of Smart Manufacturing with HIITIO

The industrial automation sector is rapidly shifting toward Silicon Carbide (SiC) MOSFETs, driven by the wide bandgap semiconductor’s unmatched efficiency and reliability. As smart manufacturing grows, so does the demand for power modules that handle higher voltages, reduce switching losses, and improve thermal management. This rising SiC adoption is transforming automation equipment, enabling smaller, faster, and more energy-efficient systems.

HIITIO stands out by offering specialized packages and customized solutions designed specifically for harsh industrial environments. Whether it’s high-voltage MOSFET modules or integrated motor drives, our products are engineered to deliver superior power density and enhanced thermal performance. This focus ensures longer lifetimes and robustness, critical for continuous operation in demanding settings.

Quality is at the core of HIITIO’s approach, with rigorous testing and strict reliability standards underpinning every device. Our precision manufacturing processes and commitment to innovation support the evolution of next-generation industrial power supplies and servo drive topologies. For reliable semiconductor solutions that meet the future needs of automation, HIITIO remains a trusted partner in smart manufacturing.

Discover how our high-voltage power modules, like those in the 62mm 1200V 450A IGBT power module series, deliver optimized performance to advanced industrial automation applications.