How to Evaluate SiC Power Module Vendors Beyond Price and Specs

Learn how to compare SiC power module vendors beyond price and datasheets by evaluating reliability, thermal management, and supply chain resilience.

Engineering Depth: Evaluating Design for Reliability (DfR)

When comparing SiC power module vendors beyond price and datasheets, engineering depth is the first critical factor to scrutinize. Understanding their design for reliability (DfR) approach reveals how thoroughly vendors address real-world application challenges, especially for high-power semiconductor modules in industrial power applications.

Dynamic Performance vs. Static Specs

Datasheets typically highlight static specifications such as voltage rating and R_DS(on), but these figures alone don’t capture module behavior under dynamic switching conditions. Effective switching loss optimization and low stray inductance reduction are crucial to improving system-level efficiency. Ask vendors about:

- Dynamic switching performance tests reflecting your target applications.

- Validation of power cycling capability and transient thermal response.

- Gate driver integration compatibility to ensure smooth switching transitions.

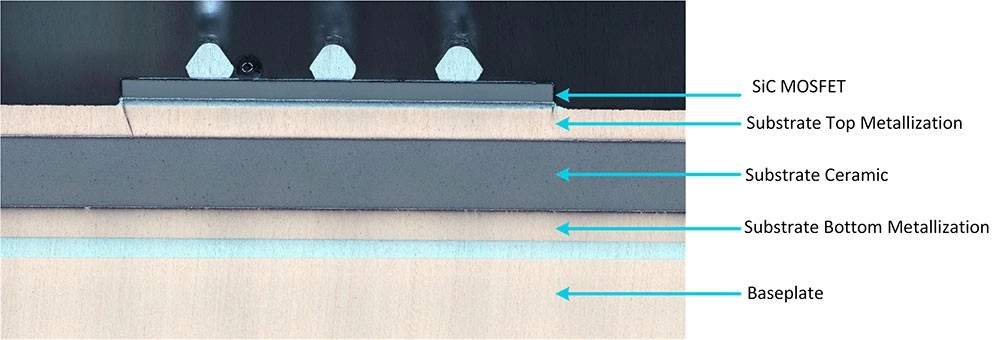

Thermal Management & Packaging Technology

Thermal performance is a cornerstone for SiC MOSFET reliability validation. Vendors investing in advanced power module thermal management feature state-of-the-art packaging materials and designs to:

- Optimize heat dissipation and reduce thermal resistance.

- Maintain robust high-voltage insulation coordination under stress.

- Support high power density without compromising lifetime.

Packaging innovations directly affect module reliability and operational margins, especially in automotive-grade or harsh industrial environments.

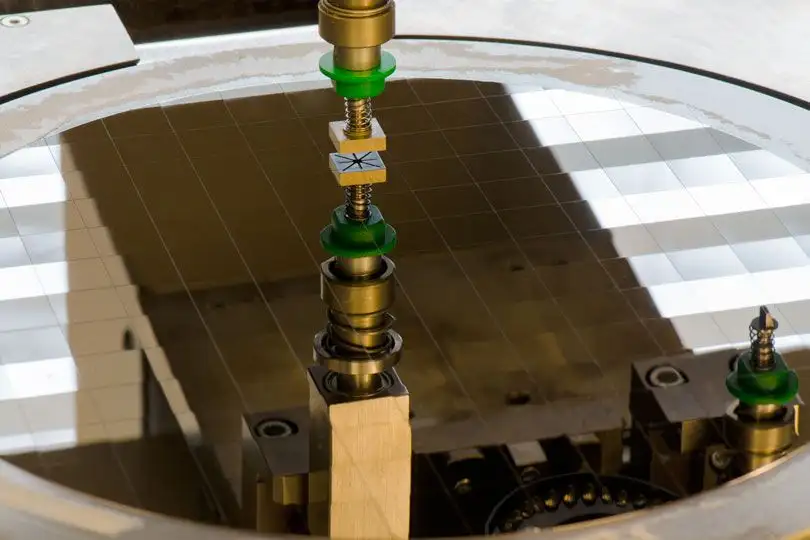

Robustness Validation

Reliability engineering demands rigorous failure mode and effects analysis (FMEA), accelerated lifetime testing, and robust validation protocols to certify long-term stability. Key areas include:

- Thermal cycling performance consistent with industry standards such as automotive-grade qualification (AQG 324).

- Mechanical stress testing and environmental resilience.

- Supplier transparency on validation data and test methodologies.

Evaluating these engineering qualities ensures the power module will not just perform on paper but sustain reliable operation throughout its lifecycle, minimizing unexpected failures and warranty risks.

By digging deeper into design factors and robustness beyond basic specs, procurement and engineering teams can separate vendors offering true power semiconductor solutions tailored for demanding power electronics systems, rather than just competitive prices on datasheets.

Manufacturing Consistency & Quality Management Systems (QMS)

When comparing SiC power module vendors, manufacturing consistency is just as critical as the specs on the datasheet. A robust Quality Management System (QMS) ensures that every power module meets tight tolerances and maintains reliability across large production runs. Look for vendors with strict process control measures, including statistical process control (SPC) and real-time monitoring to minimize variability.

Traceability is another key factor. Vendors who provide full traceability—from raw materials through finished product—help you track and resolve issues quickly if ever needed. This transparency also supports audit readiness and regulatory compliance, crucial in industries like automotive or industrial power applications.

Certification and compliance with standards such as automotive-grade qualification (AQG 324) demonstrate a vendor’s commitment to reliability and safety. These certifications often include rigorous validation processes covering power cycling capability and high-voltage insulation coordination. Vendors backing their products with these certifications typically provide more confidence for long-term, stable system-level design.

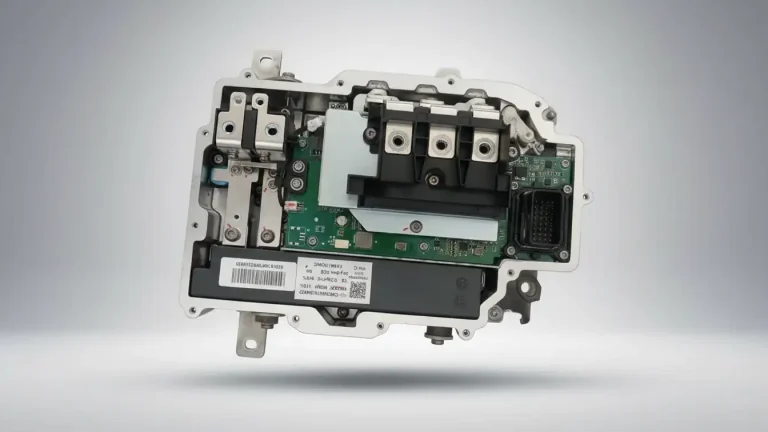

For example, SiC power modules with proven manufacturing consistency and robust QMS, like the ED3S 750V 800A SiC power module, are better positioned to support industrial power applications that demand both high efficiency and reliability.

Key points to check:

- Statistical process control & manufacturing repeatability

- Comprehensive traceability systems

- Compliance with AQG 324 or equivalent certifications

- Supplier audit checklists focused on process and quality management

Evaluating these aspects helps ensure you’re not just buying a product, but a reliable power electronics solution fit for your application’s long-term demands.

The “Hidden” Spec: Engineering Support & Collaboration

When comparing SiC power module vendors, you can’t overlook engineering support and collaboration—this is often the hidden spec that separates good suppliers from great ones. Beyond datasheets and price tags, strong design-in support can save time and avoid costly design iterations. Expert vendors provide hands-on assistance with power module integration, system-level design considerations, and even gate driver integration to optimize switching loss and system-level efficiency.

Customization also plays a key role. While off-the-shelf modules are convenient, tailored solutions can address specific reliability and power density requirements, improve stray inductance reduction, and deliver superior thermal management. Vendors who offer collaboration on custom packaging and high-voltage insulation coordination can significantly boost your product’s robustness and performance.

In short, prioritize vendors that treat engineering support as part of their power electronics solutions, not just a bonus. This partnership mindset ensures you’re not only buying components but also reliable expertise—critical for industrial power applications where long-term success depends on thorough design for reliability and system efficiency optimization.

Become HIITIO Happy Partner

For deeper reliability insights and design collaboration, vendors with proven automotive-grade qualification (AQG 324) and established failure mode and effects analysis (FMEA) processes often stand out. Check out reliability testing of power modules for an example of how thorough validation ties directly to engineering support.

Supply Chain Resilience & Long-Term Strategy

When comparing SiC power module vendors, supply chain resilience is a critical factor beyond just price and specs. A solid security of supply ensures your projects won’t stall due to component shortages or delays, which is essential in today’s unpredictable global market. Look for vendors with proven track records of consistent delivery and diversified manufacturing sites to reduce risk.

Long-term lifecycle management also matters. Vendors that commit to extended product availability and clear end-of-life plans help avoid sudden redesigns or costly qualification processes mid-project. This strategic approach supports stable sourcing and lowers the risk of costly supply disruptions down the road.

To confidently assess a vendor’s supply chain robustness, ask for a detailed vendor audit checklist that covers risk mitigation strategies, inventory buffers, and responsiveness to demand spikes. Remember, resilient supply chains directly contribute to system-level efficiency and overall project reliability, two must-haves for high-power semiconductor modules applied in critical industrial power applications.

For a deeper understanding of quality manufacturing and consistency behind resilient power semiconductor solutions, you can explore options like the advanced 1200V 600A IGBT module with integrated features to appreciate how vendors support both manufacturing and supply chain excellence.

The Financial Reality: Total Cost of Ownership (TCO)

When evaluating SiC power modules, focusing solely on the upfront price can be misleading. The real metric to consider is the total cost of ownership (TCO), which covers not just the purchase price but also ongoing expenses like maintenance, energy efficiency, and lifecycle support.

Price vs. Cost: What Matters More?

- Initial price might look attractive, but a lower-cost module with poor reliability or higher losses can drive up your system’s overall expenses.

- Modules with better switching loss optimization and superior power module thermal management typically reduce energy waste and cooling costs, improving your long-term returns.

- Investing in modules validated through rigorous SiC MOSFET reliability validation and power cycling capability lowers failure rates, cutting down downtime and repair costs.

Lifecycle Cost Analysis for Smarter Purchasing

- A thorough lifecycle cost analysis includes factors like warranty, spare parts availability, and future upgrades.

- Consider the ease and cost of integration, including gate driver integration and customization options, which can affect installation and system-level efficiency.

- Modules compliant with standards such as automotive-grade qualification (AQG 324) ensure robust performance over time, reducing replacement and requalification expenses.

Choosing the right vendor means balancing price with these broader cost factors. It’s about understanding how system-level design considerations and power module design influence your total cost, not just the sticker price. A strategic approach here safeguards your investment over the module’s entire operational lifecycle.