When Lower Power Module Cost Increases Total System Lifecycle Expenses

Discover why choosing lower-cost power modules can increase total system lifecycle costs due to thermal, reliability, and supply chain risks.

In power electronics procurement, the temptation to cut costs by selecting lower-priced modules is strong, especially in competitive markets like renewable energy and electric vehicles. But what looks like savings on the surface often hides a costly reality: lower module cost can drive up the total system lifecycle cost dramatically. From increased thermal management expenses to accelerated failure rates, these hidden factors inflate the Total Cost of Ownership (TCO) far beyond the initial price tag. Understanding this balance is critical for procurement managers and engineers aiming to optimize both performance and long-term value.

Introduction: The Procurement Dilemma in Power Electronics

In today’s renewable energy and electric vehicle (EV) markets, original equipment manufacturers (OEMs) face intense pressure to lower bill of materials (BOM) costs for high-power semiconductor modules. This often leads to purchasing decisions heavily focused on the sticker price of power modules, promoting a false economy that overlooks critical factors beyond the initial cost.

However, the true metric for evaluating power semiconductor solutions is the Total Cost of Ownership (TCO)—which encompasses not just the purchase price but also the long-term expenses of integration, reliability, maintenance, and system efficiency. OEMs must consider system-level cost optimization rather than short-term savings to ensure competitiveness and sustainability.

Our thesis is clear: while cutting costs on power modules might reduce upfront expenses, it frequently leads to hidden engineering costs throughout design, manufacturing, and ongoing power electronics lifecycle analysis. These unseen penalties inflate overall system lifecycle cost, especially in industrial power applications where reliability and performance are paramount. Recognizing the complex balance between module cost and system value is essential for effective power electronics engineering and strategic sourcing.

The Engineering Ripple Effect: How “Cheap” Modules Inflate System Design Costs

Choosing lower-cost power modules often seems like a smart move upfront, but it quickly triggers hidden engineering costs that inflate overall system expenses. One major factor is thermal management penalties. Modules with higher thermal resistance demand oversized cooling solutions—such as larger heatsinks, more powerful fans, or even liquid cooling systems. This not only drives up the system-level cost optimization challenge but also adds to the system’s weight and complexity, impacting power density trade-offs critical in power electronics systems.

Next, there’s the issue of derating and component oversizing. Budget power modules often require operating below their maximum ratings to maintain reliability, forcing engineers to add multiple modules in parallel. This creates a need for more complex electrical isolation and additional circuitry, nullifying the initial savings on module price and complicating system integration. Such oversizing also affects power module thermal management and the overall footprint of the design.

Lastly, EMI and filtering complications arise from poorer switching characteristics commonly found in low-cost power semiconductors. These impair the system’s electromagnetic compatibility, necessitating expensive filters and additional EMI mitigation components to meet compliance standards. The need for improved power module design and enhanced system efficiency optimization means that what looks cheap initially ends up costing more in engineering effort and materials.

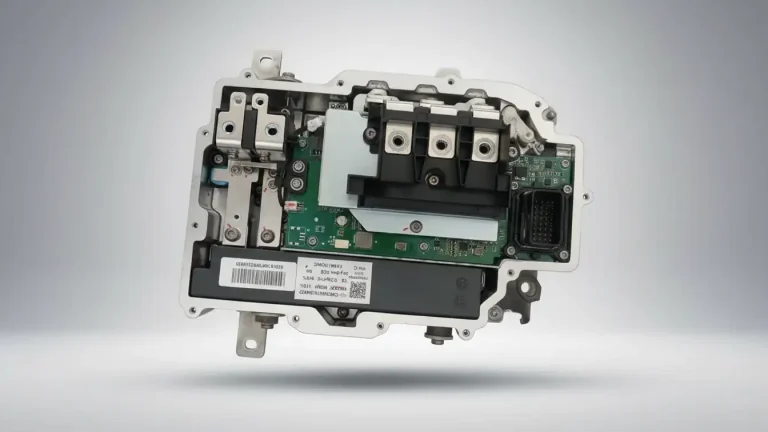

For instance, using reliable, high-performance modules like the 1000V 600A Easy 3B IGBT Power Module can significantly reduce these design penalties by delivering better thermal and switching performance, ultimately lowering the total cost of ownership (TCO) in the long run.

The Reliability Tax: Failure Modes and Operational Risks

When choosing power semiconductor modules, the high cost of failure can far outweigh the initial savings on cheaper components. In critical applications like rail traction power electronics, a single module failure often triggers costly system downtime, emergency repairs, and disrupted operations — costs that dwarf the module’s purchase price.

Budget modules frequently hide serious weaknesses. Issues like bond wire fatigue, solder joint degradation, and poor performance under thermal cycling are common failure modes often overlooked without rigorous reliability validation. These hidden defects can lead to premature failures that jeopardize system robustness and increase warranty and maintenance costs significantly.

A thorough lifecycle cost analysis (LCA) highlights how these reliability issues translate into long-term expenses. For instance, modules with a lifespan of 5 years instead of 15 require more frequent replacements, increasing both CAPEX and OPEX. This is especially critical in energy storage systems (ESS), where longevity directly affects ROI and system efficiency. Investing upfront in reliable modules and validated design reduces the overall total cost of ownership (TCO) by minimizing operational risks and maintenance overheads.

For systems demanding robustness and durability, selecting power modules with proven thermal cycling performance and extensive failure mode analysis—such as HIITIO’s 1700V IGBT power modules—ensures long-term reliability and lowers lifecycle costs. Explore HIITIO’s offerings like the 62mm 1700V 300A IGBT power module designed for demanding industrial and transportation applications.

IV. Supply Chain and Manufacturing: The Hidden “Soft” Costs

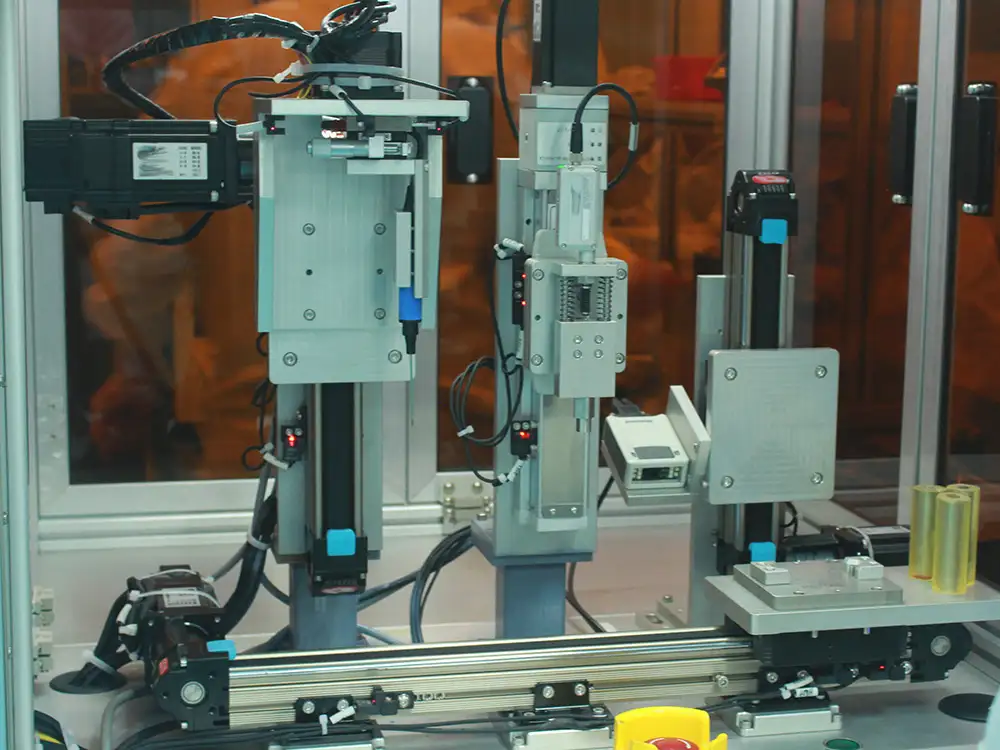

When OEMs focus solely on lowering the upfront price of power semiconductor modules, the supply chain and manufacturing costs can quietly add up. Cheaper suppliers often have wider production tolerances, which means more variability in module performance. This results in higher scrap rates and the need for extended testing cycles to ensure quality, pushing up manufacturing expenses. Such inconsistencies undermine design for manufacturing (DFM) efforts and complicate system-level cost optimization.Supplier stability is another critical yet often overlooked factor. Budget module suppliers may lack the engineering support capability necessary for rapid issue resolution. This can force costly redesigns, requalification, and delay your product’s time-to-market—hurting your CAPEX and OPEX long-term. Evaluating suppliers through a rigorous power module supplier evaluation that includes quality management system (QMS) robustness and production consistency is key for risk mitigation.

Partnering with suppliers who prioritize reliability engineering and provide comprehensive support helps prevent the hidden costs in the supply chain. For example, the 1100V 600A Easy 3B IGBT power module offers not just competitive specs but consistent manufacturing quality and strong supplier backing, ensuring smooth production and leaner warranty costs. Addressing these “soft” costs upfront improves your power electronics systems’ total cost of ownership (TCO) rather than just cutting the module purchase price.

V. Strategic Sourcing: Balancing Cost vs. Performance

For OEMs in power electronics, the sourcing strategy goes beyond chasing the lowest unit price. Supplier reliability assessments must account for the full total cost of ownership (TCO), weighing cost versus performance trade-offs. Choosing a cheaper power module can compromise system-level cost optimization by introducing hidden engineering costs, higher maintenance, and warranty expenses.

At HIITIO, we take a different approach. Rather than just offering the lowest upfront cost, we partner with OEMs to optimize their entire system efficiency. Through thorough failure mode analysis and stringent reliability validation processes, we help minimize unexpected downtime and costly redesigns—resulting in the lowest TCO over the lifecycle of industrial power applications. Our portfolio, including advanced modules like the 1200V 450A IGBT power module, demonstrates how investing in quality pays off long-term.

This strategic sourcing mindset ensures high-voltage system efficiency, improved reliability engineering outcomes, and a competitive edge in critical sectors like renewable energy, electric vehicle power systems, and industrial automation. It’s not about finding the cheapest module but achieving the best value throughout the power electronics lifecycle.

Investing in Long-Term Competitiveness

Choosing lower-cost power modules might seem like a quick win, but it often leads to hidden engineering costs, increased warranty claims, and unexpected expenses throughout the system lifecycle. These hidden costs can outweigh initial savings, impacting your total cost of ownership (TCO) and system reliability.

The final verdict is clear: investing in reliable, high-quality power semiconductor solutions saves money in the long run, especially for industrial and critical infrastructure power electronics applications. Reliable modules reduce downtime, improve thermal management, and lower maintenance costs, making your system more robust and efficient.

To optimize your system value, we encourage OEMs and engineers to prioritize lifecycle cost analysis over just upfront costs. Collaborate with HIITIO’s experts to integrate proven high-power semiconductor modules designed for long-term reliability and system-level cost optimization. Explore our 1200V 900A IGBT power modules for high-performance industrial applications and start building power electronics systems that deliver true value across their entire lifecycle.