Silicon Carbide in Welding Machines: Replacing IGBT Technology

Silicon carbide technology is revolutionizing welding equipment by replacing traditional IGBTs with superior SiC MOSFETs. Explore the technical advantages and discover five trusted wholesale suppliers—led by HIITIO—offering comprehensive SiC module solutions for modern welding inverters.

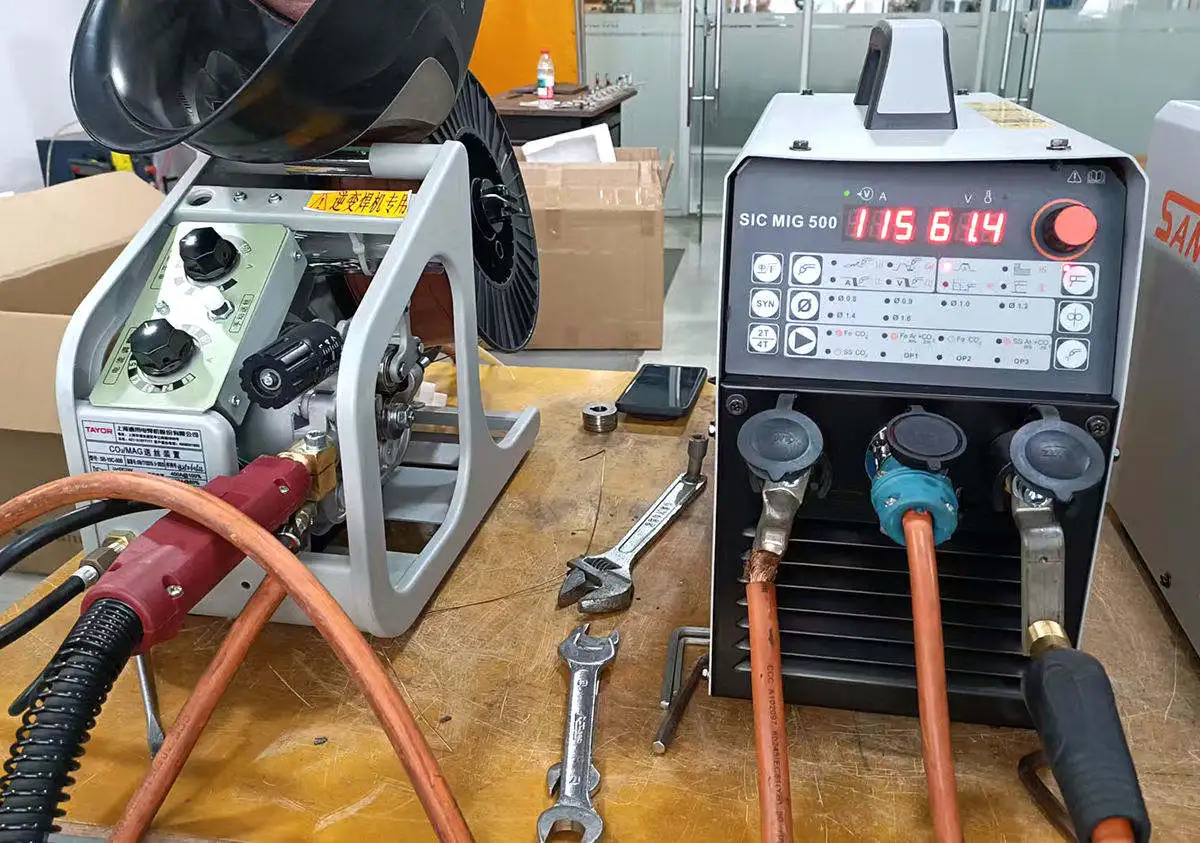

The welding industry is experiencing a transformative shift as silicon carbide (SiC) semiconductor technology increasingly replaces traditional insulated gate bipolar transistors (IGBTs) in inverter welding machines. This technological evolution delivers substantial performance improvements, enhanced efficiency, and reduced operational costs. For manufacturers and distributors seeking reliable SiC module suppliers, understanding both the technology advantages and trusted wholesale partners is essential for competitive positioning in today’s market.

Silicon carbide MOSFETs offer compelling advantages over conventional silicon IGBTs, particularly in high-power welding applications. The material properties of SiC enable superior thermal conductivity, faster switching speeds, and lower power losses, translating directly into more compact, efficient, and reliable welding equipment. As the industry transitions toward these advanced semiconductors, identifying established suppliers becomes critical for businesses aiming to stay ahead of market demands.

Why Silicon Carbide Outperforms IGBT in Welding Machines

Superior Thermal Management and Efficiency

Silicon carbide demonstrates thermal conductivity approximately three times higher than silicon, enabling welding machines to operate at elevated temperatures without performance degradation. This characteristic proves particularly valuable in industrial environments where equipment faces continuous high-temperature operation. SiC MOSFETs maintain stable performance characteristics even at junction temperatures exceeding 175°C, whereas traditional IGBTs experience significant efficiency losses under similar thermal stress.

The efficiency gains translate into measurable cost savings. Studies indicate that replacing IGBTs with SiC MOSFETs can reduce switching losses by 60-80%, depending on the converter design and operating parameters. For a typical 3kW welding inverter, this efficiency improvement means lower energy consumption and reduced cooling requirements, enabling manufacturers to design more compact units without sacrificing performance or reliability.

Enhanced Switching Performance

The switching speed advantage of SiC technology fundamentally changes welding machine design possibilities. While IGBTs typically operate at switching frequencies below 25kHz, SiC MOSFETs can achieve frequencies exceeding 70kHz without excessive losses. This higher frequency capability reduces the size requirements for passive components such as transformers and inductors by up to one-third, directly impacting system cost and weight.

Faster switching also enables more precise current control during the welding process. This precision improves weld quality, particularly in applications requiring accurate heat input control, such as thin-gauge materials or specialized alloys. The elimination of the IGBT’s characteristic tail current during turn-off further reduces switching losses and simplifies thermal management design.

Compact Design and Reduced System Complexity

Traditional IGBT-based welding power supplies require extensive cooling infrastructure and multiple semiconductor devices to achieve desired power ratings. A conventional 100kW HFI welder utilizing silicon technology requires approximately 64 IGBT devices, whereas the equivalent SiC-based design accomplishes the same output with only 4 SiC MOSFET semiconductors. This dramatic reduction in component count simplifies manufacturing, improves reliability, and reduces bill of materials costs.

The higher operating temperature capability of SiC devices often eliminates the need for additional cooling systems. In many applications, passive cooling or simplified active cooling suffices, reducing overall system size and potentially eliminating costs associated with fans, heat exchangers, or liquid cooling loops. These advantages enable portable welding equipment designs that were previously impractical with IGBT technology.

Five Leading Wholesale Suppliers for SiC Modules

1. HIITIO

- Founded: 2018

- Location: Zhejiang, China

- Core Products: SiC Modules, IGBT Modules, High Voltage DC Contactors, Semiconductor Fuses, Power Modules

- Official Website: https://www.hiitio.com/

SiC Module Products: https://www.hiitio.com/semiconductor-power-module/sic-power-semiconductor-module/

HIITIO stands as a premier electrical components manufacturer specializing in power semiconductor modules for new energy industries, including welding equipment applications. Established in 2018 and headquartered in Zhejiang, China, HIITIO emerged from Hecheng Electric’s introduction of a mature research and development team. The company operates from a 30,000 square meter manufacturing facility implementing IATF16949 quality management systems with fully automated production lines controlled by MES systems. HIITIO serves over 500 customers across 50+ countries, leveraging 20 years of accumulated electrical industry expertise to deliver safety, stability, and top-tier quality in every component.

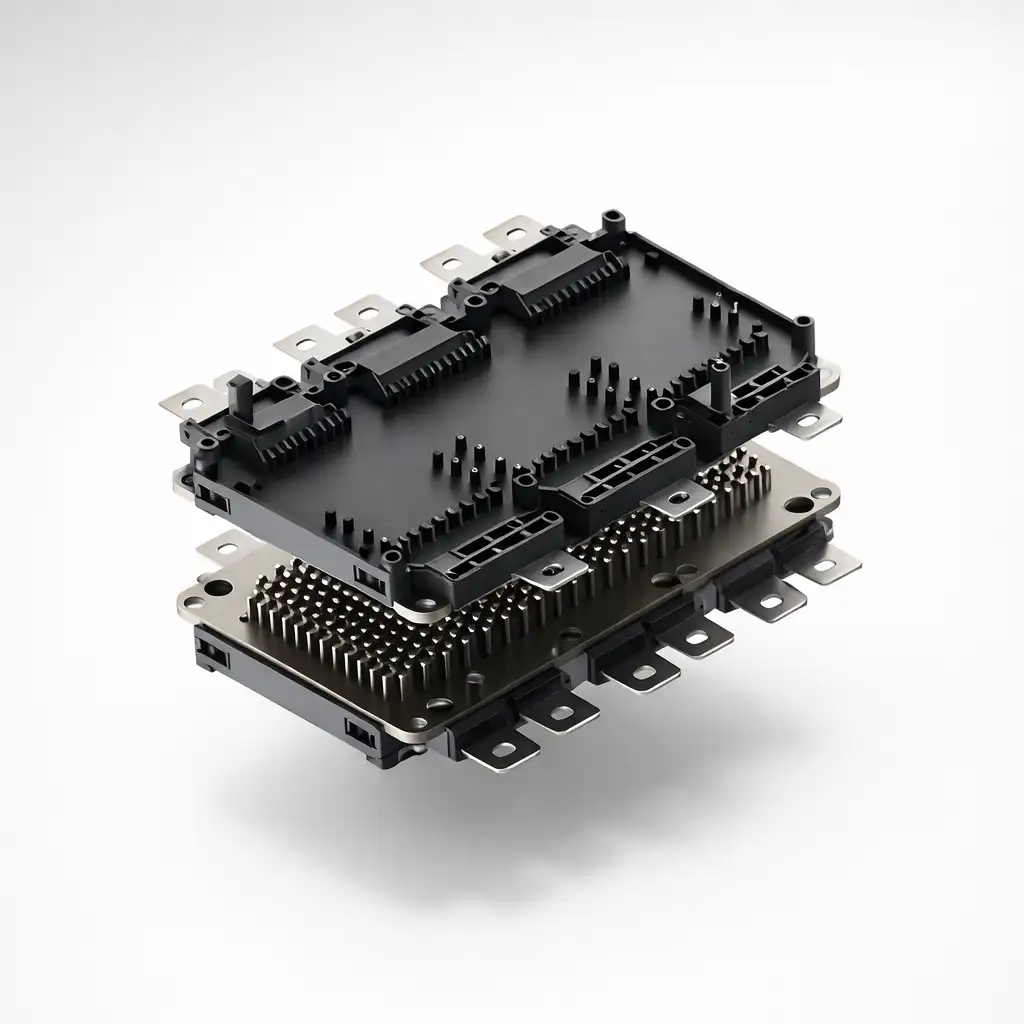

Signature Products:

HIITIO’s SiC Module product line encompasses comprehensive solutions for power conversion applications. Their semiconductor power module portfolio features full SiC MOSFETs, SiC/Si hybrid modules, and discrete SiC components designed for demanding industrial environments. These modules deliver exceptional switching performance with industry-leading thermal management capabilities, making them ideal for welding inverters requiring high reliability and compact form factors. Each module undergoes rigorous testing in HIITIO’s advanced laboratory facilities, ensuring compliance with international certifications including UL, CSA, TUV, CCC, and CE standards.

2. Infineon Technologies

- Founded: 1999

- Location: Neubiberg, Germany (Global headquarters)

- Core Products: CoolSiC MOSFETs, Power Modules, Automotive Semiconductors, Gate Driver ICs

- Official Website: https://www.infineon.com/

Infineon Technologies represents one of the world’s most established silicon carbide manufacturers, bringing over 20 years of SiC development heritage to the power electronics industry. Founded in 1999 through the spin-off from Siemens AG, Infineon has evolved into a global semiconductor powerhouse headquartered in Neubiberg, Germany. The company maintains complete vertical integration of its SiC supply chain, from substrate production through device fabrication and module assembly. Infineon’s automotive qualification (AQG-324) and extensive production capacity position them as a trusted partner for high-volume applications requiring proven reliability and consistent quality. Their investment in 200mm SiC wafer technology demonstrates long-term commitment to advancing silicon carbide manufacturing efficiency.

3. Mouser Electronics

- Founded: 1964

- Location: Fort Worth, Texas, USA (750,000 sq ft distribution center)

- Core Products: Electronic Components Distribution, SiC Power Modules, Passive Components, Interconnects

- Official Website: https://www.mouser.com/

- Power Semiconductors Category: https://www.mouser.com/electronic-components/

Mouser Electronics operates as one of the industry’s foremost authorized electronic component distributors, serving the global engineering and procurement community from its state-of-the-art facility south of Dallas, Texas. Established as part of the Berkshire Hathaway family of companies, Mouser distinguishes itself through rapid new product introduction capabilities and comprehensive inventory management. The company stocks over 5 million products from more than 700 leading manufacturers, including extensive selections of SiC modules and related power semiconductors. Mouser’s multilingual website and 23 international support locations ensure accessibility for customers in over 220 countries and territories. Their award-winning customer service, combined with same-day shipping capabilities, makes them an invaluable resource for both prototype development and production procurement.

4. Digi-Key Electronics

- Founded: 1972

- Location: Thief River Falls, Minnesota, USA

- Core Products: Electronic Component Distribution, SiC Semiconductors, Development Tools, Engineering Resources

- Official Website: https://www.digikey.com/

- Manufacturer Line Card: https://www.digikey.com/en/supplier-centers

Digi-Key Electronics has established itself as the preferred distributor for engineers, designers, and procurement professionals worldwide through its commitment to technical excellence and comprehensive product selection. Operating from a centralized distribution facility in Thief River Falls, Minnesota, Digi-Key maintains one of the industry’s widest selections of authorized electronic components backed by robust online resources and 24/7 customer support. The company serves as an authorized distributor for over 3,000 industry-leading suppliers, ensuring authentic products sourced directly from manufacturers. Digi-Key’s engineering-centric approach includes extensive design tools, reference materials, and technical documentation, positioning them as a valuable partner throughout the development cycle from concept to production.

5. Arrow Electronics

- Founded: 1935

- Location: Phoenix, Arizona, USA (Global headquarters)

- Core Products: Electronic Component Distribution, Power Semiconductors, Supply Chain Solutions, Engineering Services

- Official Website: https://www.arrow.com/

- Power Products: https://www.arrow.com/en/products/semiconductors/discrete-semiconductors

Arrow Electronics provides comprehensive electronic component distribution services with particular emphasis on supply chain management and technology integration. Founded in 1935 and headquartered in Phoenix, Arizona, Arrow has evolved into a global enterprise offering value-added services that extend beyond traditional distribution. The company’s extensive product portfolio encompasses semiconductors, passive components, interconnects, and complete system solutions. Arrow’s technical expertise in power electronics, combined with their logistics capabilities and design engineering support, positions them as a strategic partner for manufacturers implementing SiC technology transitions. Their global reach ensures consistent component availability and technical support across multiple regions, critical for international welding equipment manufacturers.

Conclusion: Partner with HIITIO for Advanced SiC Solutions

As the welding industry transitions to silicon carbide technology, selecting the right component supplier becomes crucial for competitive success. HIITIO offers a compelling combination of technical expertise, manufacturing excellence, and customer-focused service that positions us as your ideal SiC module partner. Our comprehensive product line spans from discrete SiC components to fully integrated power modules, all manufactured under stringent IATF16949 quality standards within our advanced 30,000 square meter facility.

Beyond superior products, HIITIO provides comprehensive technical support throughout your development cycle. Our experienced engineering team offers application assistance, thermal design guidance, and customization services to optimize modules for your specific requirements. Contact HIITIO today to discover how our SiC modules can elevate your welding equipment performance, efficiency, and market competitiveness.