High-Efficiency SiC MOSFETs for Solar Inverters and Energy Storage Systems

Explore high-efficiency SiC MOSFETs for solar inverters and energy storage systems offering superior thermal performance and power density.

The Shift to Wide Bandgap: Why Solar and ESS Demand SiC

The solar and energy storage system (ESS) markets are rapidly evolving, driven by the urgent need for higher efficiency and reliability in power conversion. One major industry trend is the move toward 1500V DC solar systems, which offer improved system efficiency and reduced balance-of-system costs. However, traditional silicon IGBTs struggle to meet these demands due to inherent limitations like higher switching losses and thermal challenges at elevated voltages.

This efficiency imperative pushes the adoption of wide bandgap semiconductor technology, with Silicon Carbide (SiC) MOSFETs emerging as a game changer. SiC’s wide bandgap properties enable devices to operate at higher voltages, temperatures, and switching speeds with significantly lower conduction and switching losses than silicon counterparts.

At HIITIO, we recognize these evolving challenges and focus on delivering high-reliability power modules optimized for green energy applications like photovoltaic (PV) inverters and ESS. Our SiC solutions are engineered to support the increased voltage ratings and thermal demands of modern solar and battery storage systems, ensuring performance and durability that meet the needs of today’s grid-tied and off-grid applications.

Key points:

- Industry shift to 1500V DC solar systems demands better power devices.

- Silicon IGBTs show limitations at high voltage and fast switching.

- SiC MOSFETs offer substantial improvements in efficiency and thermal resilience.

- HIITIO commits to reliable, high-performance SiC power modules tailored for renewable energy.

This shift to wide bandgap semiconductors is reshaping how solar inverters and energy storage systems are designed, delivering higher power density and longer service life for cleaner energy solutions.

Technical Superiority: SiC MOSFETs vs. Silicon IGBTs

When comparing SiC MOSFETs to traditional Silicon IGBTs, the differences in efficiency and performance are clear. SiC stands out mainly due to its wide bandgap semiconductor properties, which enable lower losses and better thermal management in solar inverters and energy storage systems.

Breaking Down Losses

| Loss Type | Silicon IGBT | SiC MOSFET | Benefit for Solar & ESS |

|---|---|---|---|

| Conduction Loss | Higher RDS(on), worsens with temperature | Very low RDS(on) with stable temperature coefficient | Lower energy loss, stable operation in hot environments |

| Switching Loss | Slower switching speeds; more energy wasted | Fast switching reduces switching losses significantly | Enables high-frequency switching topologies, cutting down size and weight |

SiC MOSFETs have a significantly lower on-state resistance (RDS(on)) that remains stable even as temperature rises. This means conduction losses stay minimal during peak operation. Their ability to switch extremely fast also slashes switching losses, which directly improves system efficiency and reduces wasted energy.

Reverse Recovery Performance

Another advantage is the near-zero reverse recovery charge (Qrr) in SiC devices. Lower Qrr results in less energy lost during switching transitions and reduces electromagnetic interference (EMI), a common challenge in high-frequency inverter circuits. This enhances the overall reliability and smooth operation of solar and ESS inverters.

Thermal Conductivity & Package Thermal Resistance

SiC MOSFETs also leverage better thermal conductivity, leading to more efficient heat dissipation.

| Package Type | Typical Thermal Resistance (Junction-to-Case) | Cooling Impact |

|---|---|---|

| TO-247 | Moderate | Standard cooling requirements |

| SOT-227 | Lower thermal resistance | Cooler operation, smaller heatsinks |

Packages like SOT-227 offer improved heat transfer compared to traditional TO-247 cases, helping systems run cooler and enabling more compact designs without compromising reliability.

For developers focused on high-reliability power modules, such as those from HIITIO’s 1200V 360A SiC power module, these technical benefits translate into higher efficiency, reduced system costs, and longer lifetime for solar inverters and energy storage systems.

Optimizing Solar Inverters with SiC Technology

Silicon Carbide (SiC) MOSFETs are game changers for solar inverter design, especially when paired with high-frequency switching. Here’s how SiC technology improves performance and efficiency in solar PV systems:

MPPT Boost Converters

- High-frequency switching enabled by SiC MOSFETs allows for much smaller inductors and capacitors in the DC-DC stage.

- This reduces component size, weight, and cost without sacrificing maximum power point tracking (MPPT) performance.

Inverter Topologies

| Type | Benefit | Application | Voltage Rating |

|---|---|---|---|

| String Inverters | Higher power density and modularity | Residential rooftop systems | Typically 600V-1000V |

| Central Inverters | Handle 1500V DC with larger breakdown voltage margin | Utility-scale solar plants | Up to 1500V DC systems |

- String inverters benefit directly from SiC’s efficiency, enabling compact, lightweight designs vital for rooftop installations.

- Central inverters leverage the high breakdown voltage of SiC devices, improving reliability and efficiency in 1500V solar systems—a standard rapidly adopted across the U.S.

System-Level Benefits

- SiC’s fast switching and low RDS(on) reduce losses, allowing smaller magnetic components, which:

- Lower overall inverter weight

- Shrink the system footprint

- Simplify thermal management

These design advantages translate to higher system efficiency and better power density—an essential edge for competitive photovoltaic power conversion solutions. For integrated power modules optimized for 1500V solar inverters, HIITIO’s 1200V/800A SiC power modules offer reliable, high-performance options tailored for next-gen PV architectures.

SiC in Energy Storage Systems (ESS): Enabling Bidirectional Flow

Energy storage systems (ESS) rely heavily on efficient bidirectional power flow — meaning they must seamlessly handle battery charging and discharging. This bidirectional challenge demands power devices that can switch rapidly and endure tough operating conditions without compromising efficiency or reliability.

Optimizing DC-DC Stages for ESS

Silicon Carbide (SiC) MOSFETs excel in the DC-DC conversion stage by improving efficiency when converting battery voltage to the DC bus. High-frequency switching enabled by SiC reduces the size of inductors and capacitors, minimizing power loss in battery-to-bus voltage conversion. This not only boosts overall system efficiency but also shrinks the converter footprint.

Thermal Management Benefits in Compact Designs

SiC’s wide bandgap allows for higher junction temperatures, which translates to improved thermal resistance and simplified thermal management. In residential ESS setups, this means smaller heatsinks or even fan-less designs become feasible — lowering cost, noise, and maintenance needs. Thanks to these characteristics, SiC MOSFETs support more compact, reliable, and quieter energy storage solutions ideal for U.S. homes and local microgrid installations.

For high-reliability and high-performance power modules that meet these demands, explore options like HIITIO’s E2 1200V 160A SiC power module designed specifically for energy storage and solar inverter applications.

Design Considerations and Integration Challenges

When integrating SiC MOSFETs into solar inverters and energy storage systems (ESS), several critical design factors come into play to ensure optimal performance and reliability.

Gate Driver Optimization

- Negative Voltage Turn-Off: Essential to fully switch off SiC MOSFETs and prevent false turn-on under high dv/dt conditions.

- dv/dt Immunity: Gate drivers must withstand rapid voltage changes without triggering unintended switching, critical for high-frequency operation.

- Gate Charge Management: Proper gate drive minimizes losses by balancing switching speed and gate voltage overshoot.

Mitigating Electromagnetic Interference (EMI)

High-speed switching of SiC devices can raise EMI concerns. To combat this:

- PCB Layout Optimization: Keep parasitic inductance low by shortening gate loop lengths and using multi-layer boards with solid ground planes.

- Snubber Circuits: Implement RC snubbers or ferrite beads to smooth switching edges and limit noise.

- Shielding and Filtering: Use EMI filters on input/output lines to reduce conducted and radiated emissions.

Short-Circuit and Avalanche Ratings

Robustness is a must for grid-connected solar and ESS applications, where transient faults can occur:

| Parameter | Importance |

|---|---|

| Short-Circuit Withstand Time | Protects MOSFETs during fault conditions |

| Avalanche Energy Rating | Ability to absorb energy spikes without failure |

| Thermal Stability | Prevents device damage at high junction temperatures |

Selecting devices with high short-circuit and avalanche ratings ensures system durability in harsh grid environments.

For tailored solutions in solar and energy storage, HIITIO offers power modules optimized for these demanding requirements, such as their 1700V Silicon Carbide Schottky diodes to complement SiC MOSFETs with minimal losses and improved efficiency.

By addressing gate driver needs, EMI mitigation, and device robustness, integrating SiC MOSFETs into photovoltaic and ESS architectures unlocks enhanced efficiency and reliability in modern power electronics.

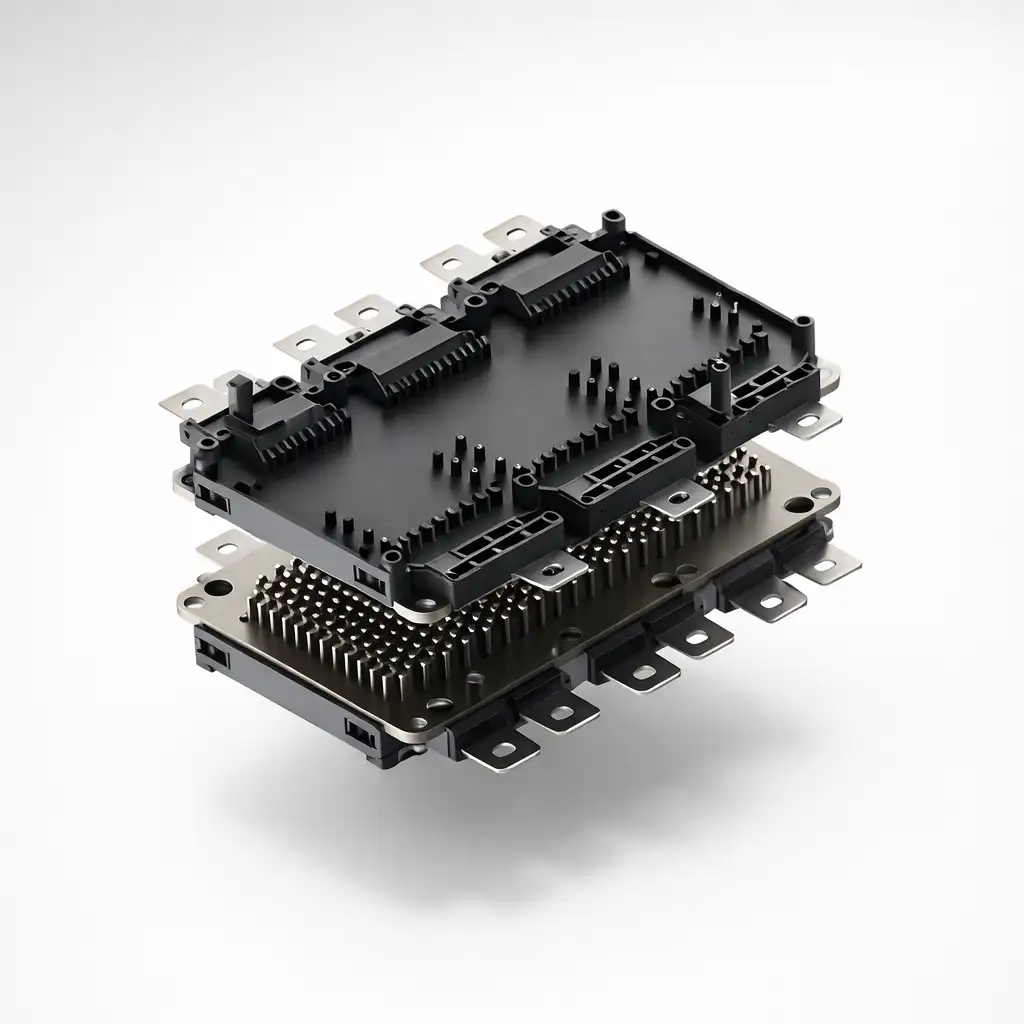

HIITIO Solutions: Powering the Next Generation

At HIITIO, we understand the importance of customized packaging to meet the demands of modern solar inverters and energy storage systems (ESS). Our use of DFN and advanced module packaging dramatically reduces parasitic inductance, improving switching performance and boosting overall system efficiency. This packaging approach supports the high-frequency switching topologies crucial for wide bandgap semiconductor efficiency in green energy applications.

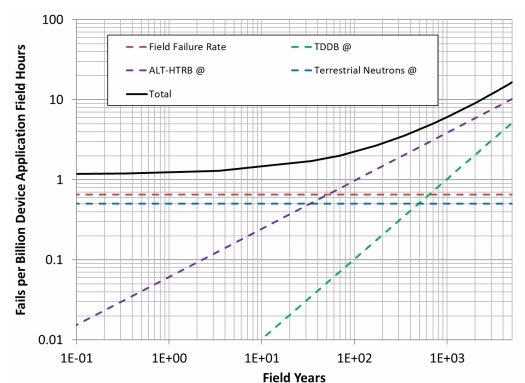

Reliability is a top priority. HIITIO’s products undergo rigorous thermal cycling and stress tests, ensuring our SiC MOSFETs and power modules maintain consistent performance under harsh grid conditions. These tests validate the robustness of devices designed for 1500V DC solar systems and high-demand ESS environments.

Moreover, we actively partner with engineers and system designers to provide expert application support. Whether selecting discrete power transistors or integrated modules for PV or ESS architectures, HIITIO delivers tailored solutions that maximize power density, reduce RDS(on) losses, and optimize thermal management.

For those needing reliable high-voltage solutions, consider our 1700V high-voltage IGBT power modules built with similar reliability standards, demonstrating our commitment to advancing power electronics for renewable energy.

This approach ensures HIITIO’s solutions are ready to power the next generation of smart, efficient, and scalable solar and energy storage inverters.

Future Outlook: The Maturation of the SiC Market

The SiC MOSFET market is rapidly maturing, driven by a clear shift in how the industry values system-level efficiency over upfront component cost. As Silicon Carbide (SiC) MOSFETs become more mainstream, the falling cost of SiC wafers is making these wide bandgap semiconductors a realistic choice not just for premium applications but also for broader solar inverter and energy storage systems in the US. This pricing trend is critical because it bridges the gap between cost and system value—allowing more manufacturers to adopt high-voltage SiC modules without compromising on reliability or efficiency.

Looking ahead, the next-generation SiC devices will focus on higher voltage ratings beyond 3.3kV, further enabling robust 1500V and even 3300V DC systems. These improvements will support more efficient power conversion in larger solar farms and utility-scale ESS installations. Additionally, integrated power modules that combine drivers, sensors, and protection features are set to simplify design complexities, lower parasitic inductance, and boost overall power density.

This progress aligns well with the growing adoption of SiC in advanced power electronics, including applications beyond PV and ESS, such as EV inverters and industrial drives. For those interested in cutting-edge reliability testing and power module innovations, HIITIO continues to push boundaries, ensuring their SiC products meet the demanding needs of the green energy revolution. You can explore more about their commitment in power modules on the HIITIO 4500V/3000A IGBT press-pack modules page.

In sum, the SiC semiconductor market’s evolution promises more efficient, compact, and cost-effective power solutions that will accelerate the shift towards smarter, greener energy systems across the US.