Press Pack IGBTs for HVDC and FACTS Reliable High-Voltage Systems

Explore the applications of Press Pack IGBTs in HVDC and FACTS systems for superior reliability thermal efficiency and series connection benefits.

Why HVDC and FACTS Demand Press Pack Technology

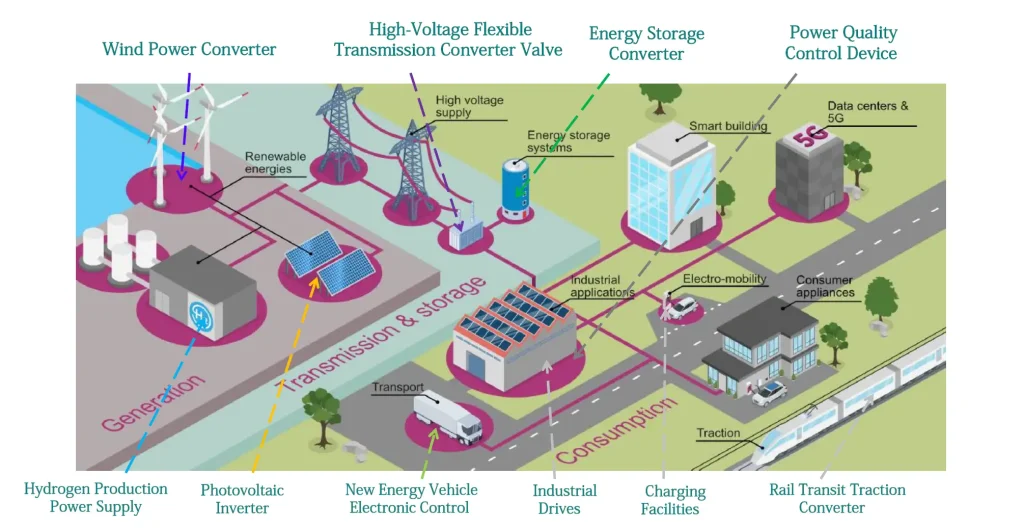

When working with HVDC (High Voltage Direct Current) and FACTS (Flexible AC Transmission Systems), engineers face challenges that demand highly reliable and robust power semiconductors. You might ask, why is press pack technology the go-to solution in these systems? The answer lies in the unique needs of these high-power grid stabilization technologies.

The Requirement for Series Connection

HVDC and FACTS systems often operate at extreme voltages and power ratings. To handle this, series-connected IGBT devices are essential. Here’s why:

- Voltage Sharing: Press pack IGBTs are designed for easy series stacking, which enables the devices to share high voltages evenly.

- Stray Inductance Reduction: Their packaging reduces stray inductances in the module, a key factor in minimizing switching losses and improving system efficiency.

- Redundancy & Reliability: Series-connected press pack IGBTs offer built-in redundancy, crucial for critical infrastructure where downtime is unacceptable.

Handling Extreme Power Densities

HVDC and FACTS systems push power densities to the limit. Managing this heat and electrical stress is where high-power semiconductor devices like press pack IGBTs shine:

- Double-Sided Cooling: This feature dramatically boosts cooling efficiency, maintaining thermal cycling reliability under heavy loads.

- Bond-wire-Free Technology: By eliminating bond wires, press pack IGBTs avoid weak points typical in conventional IGBT stacks, enhancing durability and short circuit failure mode (SCFM) characteristics.

- Clamping Force Management: The clamping force semiconductor design ensures consistent mechanical pressure, which is vital to sustaining electrical and thermal contact during rapid power cycling.

In short, press pack IGBTs provide the sturdy, scalable, and thermally resilient foundation that HVDC and FACTS applications demand—making them indispensable for modern grid solutions that prioritize performance and reliability.

Key Technological Advantages of Press Pack IGBTs

Press pack IGBTs bring some crucial benefits that set them apart in high power semiconductor devices, especially in HVDC and FACTS systems. Here’s what makes them stand out:

Bond-Wire-Free Design

Traditional IGBT modules rely on bond wires to connect chips, which can fail under stress or thermal cycling. Press pack IGBTs eliminate bond wires, providing:

- Higher reliability under rapid power changes

- Reduced stray inductance, improving switching performance

- Better durability during thermal cycling, which is common in HVDC systems

Double-Sided Cooling

The design allows cooling from both sides of the device, giving:

- Improved heat dissipation for handling extreme power densities

- Enhanced thermal cycling life, which reduces failure risks

- More compact and efficient packaging, great for high power density applications

Short Circuit Failure Mode (SCFM) – The Critical Differentiator

SCFM is a unique safety mechanism in press pack IGBTs:

- Under short circuit, the device enters a predictable failure mode without catastrophic damage

- This reduces downtime and eases maintenance in critical transmission equipment like Voltage Source Converter (VSC-HVDC) stacks

- Helps maintain system stability and protects series-connected IGBT devices

| Feature | Benefit | Impact |

|---|---|---|

| Bond-wire-free technology | No fragile connections | Higher reliability and lifetime |

| Double-sided cooling | Better heat management | Handles higher power densities |

| Short Circuit Failure Mode | Predictable failure under fault conditions | Improved system safety and uptime |

This combination of bond-wire-free design, double-sided cooling efficiency, and SCFM makes press pack power semiconductors ideal for demanding HVDC and FACTS installations. For a deeper look at advanced semiconductor packaging, check out HIITIO’s powerful silicon carbide power modules designed for high-performance applications.

EXPLORE MORE HIITIO PRESS PACK IGBT

Applications in VSC-HVDC Transmission

Press pack IGBTs play a vital role in Voltage Source Converter (VSC-HVDC) systems, especially within Modular Multilevel Converters (MMC). These IGBT-based converters enable efficient, reliable high-voltage direct current transmission across long distances, making them crucial for modern grid infrastructure.

The press pack IGBT’s bond-wire-free technology and double-sided cooling design allow for better heat dissipation and higher power densities, which directly improve the MMC’s performance. This means less energy loss and more stable power delivery during voltage conversion, boosting overall transmission efficiency.

Using press-pack power semiconductor devices in series-connected IGBT stacks also helps reduce stray inductance, essential for smooth switching in VSC-HVDC systems. This directly supports grid stability and faster response times, which are critical in large-scale power transfers.

For those developing or upgrading high-power semiconductors in this field, options like HIITIO’s 1200V 300A Easy 3B IGBT power module provide a reliable, high-performance package tailored to VSC-HVDC requirements, including robust thermal cycling reliability and short circuit failure mode (SCFM) protection.

In the press pack IGBTs enable MMC-based VSC-HVDC systems to deliver higher efficiency, greater scalability, and improved durability—key factors for the evolving U.S. energy grid.

Applications in FACTS (Flexible AC Transmission Systems)

Press pack IGBTs play a crucial role in FACTS technologies like STATCOM (Static Synchronous Compensator) and SVC (Static Var Compensator) modernization. These systems are fundamental for grid stabilization technologies, helping balance voltage and improve power quality in transmission networks.

STATCOM and SVC Modernization

- STATCOMs rely on fast-switching, reliable press pack power semiconductor devices to provide dynamic reactive power compensation. The bond-wire-free IGBT technology in press pack modules ensures excellent thermal cycling reliability and reduces stray inductance, which directly improves switching performance for rapid voltage regulation.

- SVC systems, traditionally using thyristors, now benefit from modernized press pack IGBT stacks offering enhanced controllability and higher power density packaging. This upgrade supports active power filtering and leads to more efficient voltage regulation under heavy load conditions.

The double-sided cooling efficiency of press pack IGBTs also extends component life and performance in these high-power applications. The clamping force semiconductor design typical of press pack IGBT modules ensures secure, stable assembly in series-connected IGBT devices, vital for the high-voltage demands of FACTS.

For U.S. grid operators seeking to improve power quality and reliability, integrating advanced press pack IGBTs—such as HIITIO’s robust 62mm 1700V 300A SIC power modules—can enhance FACTS installations with proven durability and supply chain stability. Their customization and rigorous testing meet the stiff demands of the American power transmission landscape.

VIEW HIITIO PRESS PACK IGBT LABORATORY

Engineering Considerations for Press Pack Integration

When integrating press pack IGBTs into high-power systems like HVDC and FACTS, careful attention to engineering details makes all the difference in reliability and performance. Two critical factors are clamping force management and explosion protection.

Clamping Force Management

Since press pack power semiconductor devices rely on uniform pressure to maintain optimal contact and electrical connection, managing the clamping force correctly is essential. Too little force can cause increased resistance and hotspots, while too much force risks damaging the semiconductor stack assembly. Proper clamping ensures consistent performance and thermal cycling reliability, especially in series-connected IGBT devices used for high-voltage applications.

Explosion Protection

Given the extreme power densities and fault conditions in HVDC and FACTS systems, press pack IGBTs must be housed in explosion-proof enclosures. This protects both the device and surrounding equipment from catastrophic failure, particularly in short circuit failure mode (SCFM) scenarios. Designing an effective explosion-proof housing minimizes safety risks and supports grid stabilization technologies by ensuring fault containment.

By addressing these engineering challenges, the press pack IGBT integration guarantees robust operation in demanding environments, making it an ideal choice for modern grid solutions. For advanced clamping and packaging options, consider tailored solutions like HIITIO’s high-power semiconductor devices that focus on durable design and performance under stress.

HIITIO PRESS PACK IGBT APPLICATION

HIITIO’s Approach to High-Power Semiconductors

HIITIO takes a hands-on approach to delivering reliable press pack IGBTs tailored for the demanding needs of HVDC and FACTS systems in the U.S. market. Their focus on customization and rigorous testing ensures each high power semiconductor device meets precise performance standards, especially for applications requiring series-connected IGBT devices and high-power density packaging. This customization extends to optimizing the clamping force semiconductor design, guaranteeing durability and stability under heavy electrical and thermal cycling loads.

Moreover, HIITIO stresses supply chain stability, a critical factor for U.S. utility companies and contractors relying on steady deliveries of cutting-edge press pack power semiconductors. This reliability minimizes project delays and ensures that large-scale deployments such as Voltage Source Converter (VSC-HVDC) and Modular Multilevel Converter (MMC) projects maintain momentum.

By combining tailored solutions with robust supply management, HIITIO supports the integration of advanced power modules—like the reliable 6500V 250A high voltage IGBT power module—that demonstrate excellent bond-wire-free technology and double-sided cooling efficiency. This makes HIITIO an ideal partner when implementing next-gen grid stabilization technologies such as STATCOM and SVC modernizations across North America.