Press Pack IGBTs for Reliable Wind Power and Grid Converters

Discover HIITIO Press Pack IGBTs offering superior thermal cycling reliability, double-side cooling, and fail-short safety for wind power and grid converters.

The Reliability Challenge in Modern Wind Energy Conversion

Modern wind turbine power converters face extreme operational demands that challenge the reliability of semiconductor components. Wind farms, especially offshore and remote installations, operate under harsh conditions—wide temperature fluctuations, high humidity, salt corrosion, and mechanical vibrations—that accelerate thermal cycling and mechanical stress on power modules. This environment exposes the weak link in standard wire-bonded IGBTs, where bond-wire fatigue and coefficient of thermal expansion (CTE) mismatches lead to premature failures.

Standard modules often struggle with stray inductance reduction and uneven current distribution in high-power semiconductor stacks, limiting their reliability in demanding grid-connected converters. Moreover, the growing complexity of grid codes and renewable integration mandates strict grid compliance for harmonics, fault ride-through, and switching performance. Semiconductor devices must support these stringent electrical and mechanical requirements without sacrificing operational uptime.

In this context, addressing the reliability challenge requires a shift from traditional high voltage IGBTs toward more robust solutions engineered to withstand harsh wind farm realities and ensure sustained performance for advanced HVDC transmission components and Modular Multilevel Converters (MMC) used in modern wind energy systems.

What Sets Press Pack IGBTs (PPI) Apart?

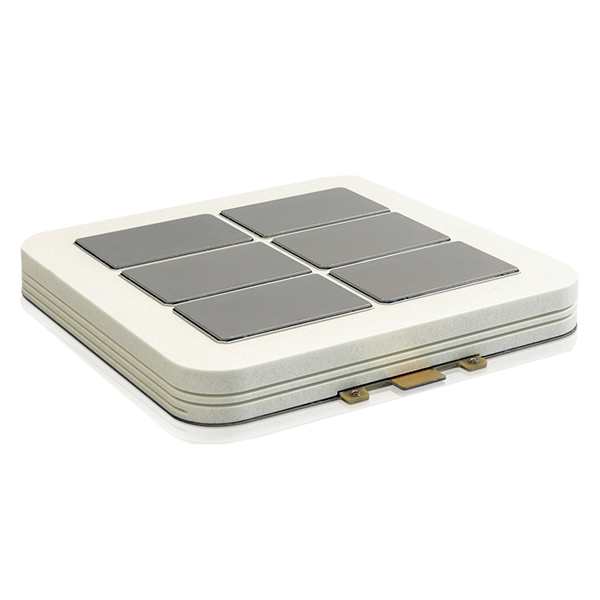

Press pack IGBTs stand out because of their unique bond-wire-free IGBT design. Unlike traditional modules that rely on fragile bond wires to connect semiconductor chips, PPIs use direct pressure contact technology. This means the semiconductor dies are clamped under uniform pressure, eliminating bond wires that can fail under mechanical stress or thermal cycling. This design drastically improves thermal cycling reliability and reduces the risk of failure caused by CTE mismatch (Coefficient of Thermal Expansion).

Another key advantage is double-sided cooling heat dissipation. By allowing cooling on both the top and bottom surfaces of the IGBT, press pack modules efficiently manage heat, enabling higher power density and longer lifetime in demanding environments like wind turbines and grid converters.

Together, these features make press pack IGBTs a robust choice for high-power semiconductor devices, especially in applications requiring series-connected IGBT devices with superior reliability. For those looking into scalable, high-voltage solutions, models like the 3300V 1000A high-voltage IGBT power module demonstrate the power and resilience of this technology.

Critical Advantages for Grid-Connected Converters & HVDC

Press Pack IGBTs (PPI) offer key benefits that make them ideal for wind turbine power converters and HVDC transmission components. One standout feature is the short-circuit failure mode (SCFM), also known as the “fail-short” characteristic. Unlike traditional wire-bonded modules, if a fault occurs, PPIs fail safely by shorting rather than opening, which prevents catastrophic damage and allows the rest of the system to keep running. This boosts overall reliability, especially in critical grid-connected applications.

Another major advantage is the series connection capability. Because PPIs use bond-wire-free construction with direct pressure contact technology, they handle higher voltages reliably when stacked in series for high-power semiconductor stacks. This reduces stray inductance and improves the performance of Modular Multilevel Converters (MMC) and FACTS devices. The result is a more robust and efficient design that simplifies HVDC and wind farm power electronics.

PPIs also feature explosion-proof housing, often with hermetic ceramic housing, which offers superior protection against environmental stresses like humidity, dust, and thermal cycling. This rugged packaging ensures long-lasting performance under the harsh conditions typical in wind farms.

For those interested in high voltage IGBT solutions combining these benefits, exploring our 3300V 1600A high voltage IGBT power module reveals the cutting edge in press pack power semiconductors designed for grid-tied applications.

HIITIO’s Approach to High-Power Semiconductor Manufacturing

At HIITIO, we focus on delivering reliable, high-power semiconductor devices that meet the tough demands of wind turbine power converters and grid-connected systems. Our expertise lies in precision clamping engineering, which ensures consistent active clamping force across the entire press pack power semiconductor stack. This key factor preserves the direct pressure contact technology that guarantees stable operation without the risk of bond-wire failures common in traditional modules.

We also tailor our bond-wire-free IGBTs and other high voltage IGBT devices to fit specific converter topologies like Modular Multilevel Converters (MMC) or HVDC transmission components. This customization enhances thermal cycling reliability and reduces CTE mismatch, critical for devices operating under constant thermal and mechanical stress on offshore and onshore wind farms.

Before delivery, every module undergoes rigorous testing designed for the extremes—simulating harsh environments experienced by wind farms, including rapid temperature changes and electrical surges. Such testing ensures the semiconductor’s robustness, especially in terms of the important short-circuit failure mode (SCFM) and thermal management through double-side cooling heat dissipation.

For customers looking for proven, high-power solutions, our range includes advanced modules like the 1000V 600A Easy 3B IGBT power module, designed with these manufacturing standards in mind. We commit to bringing you reliable power semiconductors that perform under pressure—literally.

Comparative Analysis: Press Pack vs. Wire-Bonded Modules

When it comes to high power semiconductor devices for wind turbine power converters, press pack IGBTs stand out against traditional wire-bonded modules. The key difference lies in their bond-wire-free IGBT construction. Unlike wire-bonded modules, where fragile bond wires connect the chip to the terminals, press pack IGBTs use direct pressure contact technology. This design eliminates common failure points caused by CTE mismatch and thermal cycling, improving reliability in harsh wind farm environments.

Here’s a quick comparison:

- Thermal Cycling Reliability: Press pack modules handle thermal stresses much better due to their clamping force semiconductor design, reducing the chances of bond wire lift-off. Wire-bonded modules can suffer from fatigue and eventual failure after repeated temperature changes.

- Stray Inductance Reduction: Press pack IGBTs offer significantly lower stray inductance since their design minimizes internal lead lengths, benefiting dynamic switching performance. This advantage is critical for Modular Multilevel Converter (MMC) topologies and HVDC transmission components where efficiency and fast response matter.

- Short-Circuit Failure Mode (SCFM): Press pack technology naturally supports a fail-short mode, meaning the device will fail safely without causing catastrophic damage to the converter. Wire-bonded devices tend to fail open, potentially leading to more severe system damage.

- Cooling Efficiency: Thanks to double-side cooling heat dissipation, press pack IGBTs handle higher power densities and maintain stable junction temperatures under heavy loads better than wire-bonded counterparts.

Overall, press pack power semiconductor devices provide enhanced durability, easier scalability for series-connected IGBT devices, and better performance for grid-connected wind power systems than wire-bonded modules. For those interested in exploring high voltage IGBTs, consider our 2400V 1700A high-voltage IGBT power module that delivers robust performance using press pack technology, ideal for demanding wind power applications.

VIEW HIITIO PRESS PACK IGBTs

Future Outlook: The Role of PPIs in Offshore Wind

Offshore wind farms are expanding rapidly in the U.S. market, and the demands on power semiconductors like press pack IGBTs (PPIs) are only growing. PPIs offer unmatched reliability thanks to their bond-wire-free IGBT design and robust direct pressure contact technology. This makes them ideal for handling the harsh offshore environment, where extreme temperature swings and rough operational conditions challenge conventional modules.

Key benefits driving PPI adoption offshore include:

- Superior thermal cycling reliability through double-sided cooling heat dissipation

- Reduced stray inductance that improves efficiency in high-power semiconductor stacks

- Proven short-circuit failure mode (SCFM) guarantees fail-short behavior, critical for grid-connected converters in wind turbine power converters and HVDC transmission components

- Their hermetic ceramic housing ensures protection from saltwater corrosion and humidity

- Easy integration into Modular Multilevel Converter (MMC) setups used in FACTS and HVDC systems

As offshore wind farms grow in scale and capacity, incorporating N+1 redundancy designs with series-connected IGBT devices becomes easier using PPIs. The clamping force semiconductor construction helps maintain long-term operational stability with minimal CTE mismatch issues, key for maintaining uptime.

For U.S. operators, this means lower maintenance costs and improved grid compliance, ensuring reliable renewable energy deliveries. To explore high-power PPIs suitable for such applications, check out our precision-engineered 1700V 450A IGBT module designed to meet these tough demands.

In sum, press-pack power semiconductors are set to become the backbone of offshore wind power converters, boosting both performance and reliability in America’s push toward sustainable energy.