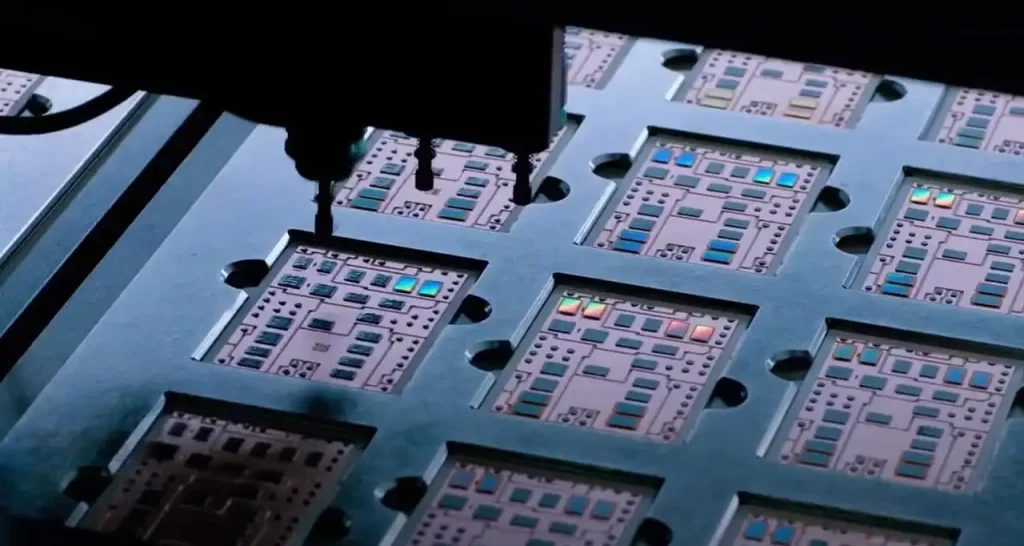

Reliability and Lifetime Testing of Power Modules for Long-Term Performance

Explore reliability and lifetime testing of power modules including power cycling thermal stress and lifetime prediction models for durable high-performance solutions.

Key Failure Mechanisms in Power Modules

Understanding the main failure mechanisms in power modules is essential for improving power module reliability and extending device lifetime. Several critical stress factors impact performance and durability:

Thermo-Mechanical Fatigue

- Bond wire lift-off: Repeated thermal cycles cause bond wires to weaken and detach from the die surface.

- Heel cracking: Stress concentration near wire bonding areas results in cracking at the bond “heel” region.

- Aluminum wire degradation: Prolonged thermal and mechanical stress leads to microstructural changes and increased resistance in aluminum bond wires.

Solder Fatigue

- Cracks develop in die-attach and baseplate solder layers due to the coefficient of Thermal Expansion (CTE) mismatch between different materials.

- These cracks impair heat dissipation and mechanical integrity, accelerating module degradation over time.

Other Common Failure Modes

- Delamination: Separation of layers inside the power module due to thermal and mechanical stress.

- Gate oxide breakdown: High voltage stress causes deterioration of gate oxides in insulation layers.

- Electromigration: Under high voltage and current density, atoms in metal lines migrate, leading to open circuits or shorts.

Application-Specific Stress Influences

- Electric Vehicles (EVs): Frequent power cycling and rapid thermal changes cause aggressive thermo-mechanical fatigue and solder layer degradation.

- Renewable Energy Systems: More stable load profiles lead to steadier thermal stresses, but long-term fatigue from environmental factors still applies.

Key failure mechanisms like bond wire fatigue, solder layer degradation, and electrical stress damage differ notably depending on the application. Recognizing these helps shape targeted accelerated lifetime testing and design improvements focused on real-world mission profiles.

Core Testing Methods for Reliability Assessment

To gauge power module reliability, testing methods focus on simulating real-world stresses and identifying failure points early. The Power Cycling Test, also known as Active Thermal Cycling, is central here. It subjects the module to repeated temperature swings—either controlled by constant junction temperature change (ΔTj) or constant case temperature change (ΔTc). This helps reveal issues like bond wire fatigue or solder layer cracks by stressing the module during operation. Control strategies monitor parameters such as collector-emitter voltage (VCE(on)) rise or increases in thermal resistance to mark end-of-life.

Passive Thermal Cycling differs by applying temperature swings without electrical load, mainly used for qualification rather than lifespan prediction. High Temperature Reverse Bias (HTRB) and High Temperature Gate Bias (HTGB) tests introduce electrical stress at elevated temperatures, accelerating key failure modes like gate oxide breakdown and electromigration.

Accelerated testing protocols combine factors such as temperature, voltage, and cycle frequency to speed up failure occurrence. These tests rely on statistically significant sample sizes and analysis techniques like the Weibull distribution to reliably estimate power module lifetime.

For practical applications requiring robust power electronics, exploring products like the 62mm 1200V 800A IGBT power module can offer insights into tested, high-reliability solutions designed with these stress factors in mind.

Lifetime Prediction Models and Analysis

Predicting the lifetime of power modules is essential for reliable operation, especially in demanding applications like electric vehicles and renewable energy systems. Common lifetime models include Coffin-Manson, CIPS08, and Bayerer, each focusing on factors such as junction temperature swing (ΔTj), maximum junction temperature (Tjm), on-time duration (ton), and bond wire current. These parameters help estimate how thermal and electrical stresses cause fatigue over time.

Using mission profile-based lifetime estimation, we translate real-world duty cycles into cumulative damage through Miner’s rule. This approach accounts for how various operating modes—like frequent cycling or steady loads—impact overall device durability. Simulation tools play a big role here, combining electro-thermal modeling with finite element stress analysis to predict mechanical stress and thermal hotspots accurately.

Lifetime models are not just theoretical—they’re validated with real field data to ensure accuracy. Additionally, there’s growing interest in second-life applications, such as repurposing electric vehicle traction inverters for stationary storage, requiring adjusted lifetime assessments based on new usage patterns.

For high-reliability needs, consider power modules like the 4500V 1200A high-voltage IGBT power module designed to withstand rigorous cycling and thermal stresses common in heavy-duty environments.

Industry Standards and Qualification Requirements for Power Modules

Meeting industry standards is critical for ensuring power module reliability and long-term performance, especially in demanding applications like automotive and industrial sectors. Here’s a quick breakdown of key standards and qualification approaches.

| Standard | Scope | Notes |

|---|---|---|

| AEC-Q101 | Automotive discrete semiconductors & modules | Most referenced for qualifying power modules in EVs and automotive systems |

| JEDEC JESD22 series | Industrial testing methods | Includes thermal cycling, power cycling, and other stress tests |

| IEC standards (e.g., IEC 60747) | International electronics testing | Broad acceptance, covers power module reliability and safety |

| AQG 324 | Robustness validation & test-to-failure | Emerging test protocols that emphasize durability beyond pass/fail |

Automotive Qualification for High-Voltage Modules and IPMs

As electric vehicles (EVs) and hybrid systems grow, compliance with automotive qualification requirements becomes even more important. High-voltage power modules, including Intelligent Power Modules (IPMs), must undergo rigorous testing to ensure they withstand harsh operating conditions and cycling stresses.

This includes:

- Thermal cycling and power cycling tests tailored for high voltage environments

- Electrical stress testing like High-Temperature Reverse Bias (HTRB)

- Verification of gate driver performance and integrated protection features in IPMs

For example, the 62mm 1200V 150A IGBT power module meets key automotive standards, providing reliable performance under high power and thermal cycles.

Staying aligned with these standards helps manufacturers create power modules that meet both safety and longevity requirements in automotive, industrial, and renewable energy applications.

Factors Influencing Lifetime and Optimization Strategies

Several factors impact the lifetime and reliability of power modules, and optimizing these can extend operational life significantly.

Design Improvements

- Advanced Packaging: Choosing between epoxy and silicone molding compounds affects stress tolerance and moisture resistance. Silicone often offers better thermal cycling durability.

- Baseplate Materials: Materials like copper or DBC (Direct Bonded Copper) influence heat dissipation and mechanical stability.

- Module Integration: More integrated designs reduce interconnections and improve mechanical integrity, lowering failure risk.

Operational Factors

- Thermal Management: Efficient cooling reduces junction temperature swings (ΔTj), directly lowering thermal fatigue in bond wires and solder layers.

- Derating: Operating below maximum ratings, especially voltage and current, reduces stress and extends lifetime.

- Switching Frequency Optimization: Balancing switching speed minimizes both conduction and switching losses, while also reducing electromagnetic interference (EMI), which can otherwise degrade components prematurely.

Material Advancements

- SiC vs. Si Modules: Silicon Carbide (SiC) power modules offer higher efficiency, better heat tolerance, and longer lifetime under harsh cycling compared to traditional silicon (Si). Products like the ED3 2200V 600A SiC power module demonstrate this enhanced durability in demanding applications.

Monitoring Techniques

- Real-time health monitoring through VCE(on) voltage shifts and accurate temperature sensing helps detect early signs of wear. This allows proactive maintenance and prevents unexpected failures.

By focusing on these design and operational factors, manufacturers and users can optimize power module reliability, ensuring longer, more efficient service life in automotive, renewable energy, and industrial applications.

Case Studies and Real-World Applications

When it comes to power module reliability, real-world use cases tell the full story. In electric vehicle (EV) traction inverters and charging systems, modules face harsh conditions with frequent thermal and power cycling. This demands robust design and testing to prevent issues like bond wire fatigue and solder layer degradation. Power modules from HIITIO, such as their high-voltage IGBT modules, have demonstrated extended lifetime performance under these tough cycling conditions, helping EV systems achieve better uptime and efficiency.

Renewable energy inverters also rely heavily on reliable power modules. Unlike EVs, renewable systems often experience steadier loads but must still withstand environmental stresses over long periods. HIITIO’s SiC power modules, designed for high temperature and switching efficiency, show strong durability in industrial drives and solar inverter applications, contributing to stable power conversion and reduced maintenance needs.

For a closer look at reliable solutions in these fields, consider HIITIO’s advanced 1200V IGBT power modules like the Econo Dual 3H 1200V 450A IGBT module, ideal for EV inverter applications, or the ED3S 1200V 400A SiC power module that supports renewable energy systems needing high efficiency and long-term reliability.

These case studies highlight how carefully engineered power modules with proven reliability testing can meet the unique demands of today’s power electronics—from fast-changing EV environments to steady, heavy-duty industrial drives—ensuring longer system lifetimes and better performance.

Future Trends in Power Module Reliability

The future of power module reliability is shaped by advances in wide-bandgap devices like SiC and GaN, which offer higher efficiency, better thermal performance, and greater durability compared to traditional silicon modules. These devices enable power modules to handle higher voltages and temperatures while reducing losses, pushing the limits of power electronics reliability.

Another key trend is the rise of Intelligent Power Modules (IPM) that come with built-in protection and diagnostic features. IPMs enhance system safety and uptime by actively monitoring parameters like junction temperature and current, providing real-time health data crucial for predictive maintenance.

Prognostics and health management (PHM) techniques will be more widely adopted, using data analytics and simulation to predict failures before they happen. This shift helps to schedule maintenance more effectively, minimizing downtime and extending the overall lifetime of power modules.

Sustainability is also becoming a top priority. Longer-lasting power modules reduce electronic waste and improve the environmental footprint of green technologies like electric vehicles and renewable energy systems. By combining higher reliability with eco-friendly design, power electronics can support a more sustainable energy future.

For applications demanding cutting-edge reliability, consider advanced options such as the 1000V 600A Easy 3B IGBT Power Module or the robust 650V 150A IGBT Power Module, which integrate these latest trends to meet stringent performance and lifetime requirements.