Trends in Intelligent Power Modules IPMs SiC GaN Efficiency Advances 2026

Discover key trends in Intelligent Power Modules IPMs including SiC and GaN technologies for higher efficiency in EVs renewable energy and industrial drives.

Market Overview and Growth Drivers

The Intelligent Power Module (IPM) market is experiencing robust growth as power electronics become essential across multiple industries. Currently valued in the several hundred million USD range, this market is projected to grow at a compound annual growth rate (CAGR) between 8% and 12% over the next five years. This steady expansion reflects rising demand for power module efficiency improvements and advanced IPM integration.

Key Growth Drivers

- Electric Vehicle Adoption: The surge in electric vehicle (EV) production is a dominant force driving IPM demand. Intelligent power modules are critical components in EV inverters and traction systems, offering enhanced power efficiency and switching loss reduction—vital for extending range and performance.

- Renewable Energy Expansion: The shift to cleaner energy sources like solar and wind power relies heavily on reliable renewable energy inverters. IPMs enable high-frequency operation and improved thermal management, helping maintain system reliability and reduce electromagnetic interference (EMI) in these applications.

- Industrial Automation: As factories and industrial settings invest more heavily in automation and robotics, industrial motor drives and IPMs are becoming essential. These modules support precise control, power density, and long-term reliability necessary in automated processes and HVAC systems.

Regional Market Insights

- Asia-Pacific (APAC): APAC leads the Intelligent Power Module market, driven by rapid EV adoption in China, expanding renewable energy projects, and strong industrial growth in Japan, South Korea, and India. The region’s focus on wide bandgap semiconductors like SiC and GaN also propels technological advancements here.

- North America: The U.S. and Canada are key players in IPM innovation, focusing on automotive-qualified IPMs and high-voltage intelligent power modules for EVs and smart grid applications. North America’s investment in charging infrastructure and advanced manufacturing enriches regional market dynamics.

Together, these growth drivers and regional influences position intelligent power modules as a cornerstone in the future of efficient, smart, and sustainable power management.

Technological Advancements in IPM Design

The rise of wide bandgap semiconductors like SiC and GaN is transforming intelligent power modules (IPMs) by offering higher efficiency, faster switching, and better thermal performance compared to traditional silicon-based modules. Integrating SiC IPM trends and GaN intelligent power modules allows for greater power density, enabling more compact and lightweight designs without sacrificing performance.

Miniaturization is another key trend, with manufacturers focusing on shrinking module size while boosting power handling capabilities. This leads to smarter gate driver configurations and on-chip intelligence, improving control precision and reducing system complexity. Advanced packaging and substrate technologies also play a critical role by supporting higher voltage and current levels, enhancing reliability and long-term durability in demanding applications.

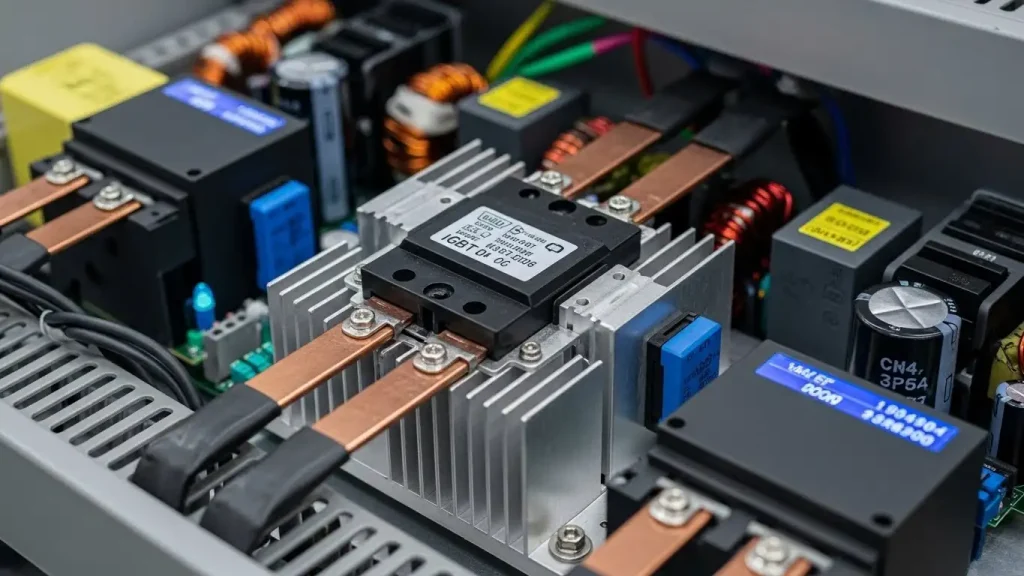

For example, solutions like our 1200V 450A IGBT module with integrated features showcase how advanced packaging helps meet modern high-voltage IPM demands, striking the right balance between size, power, and thermal management.

These technological leaps contribute directly to improved power module efficiency, making IPMs a better fit for high-frequency power modules across automotive, renewable energy, and industrial motor drives.

Key Performance Trends in Intelligent Power Modules (IPMs)

Intelligent Power Modules (IPMs) are evolving to deliver better power efficiency by reducing both conduction and switching losses. These improvements help lower energy waste and heat generation, which is critical for applications like electric vehicle inverters and industrial motor drives. High-frequency operation is another key trend, allowing IPMs to shrink the overall system size while maintaining performance, making devices more compact and lightweight.

Managing electromagnetic interference (EMI) is increasingly important as IPMs operate at higher speeds. Advanced EMI mitigation strategies are being integrated into IPM designs to ensure stable operation without disrupting surrounding electronics. On top of that, thermal management is receiving attention with enhanced cooling solutions and materials that boost reliability, extending the lifespan of modules under demanding conditions.

These combined advances support power module efficiency improvements and high-frequency power modules that meet the demanding requirements of today’s markets, ensuring robust, reliable performance in automotive qualified IPMs and industrial motor drives. For example, HIITIO’s 1200V SiC power modules showcase these performance trends with optimized low-loss switching and effective thermal handling.

Application-Specific Trends in Intelligent Power Modules (IPMs)

Intelligent Power Modules are adapting rapidly to meet the demands of key application areas. In electric vehicles, IPMs power inverters and traction systems, helping improve efficiency and reliability crucial for EV performance. These modules are designed to handle high power and fast switching, making them perfect for automotive qualified IPMs supporting traction motors.

In renewable energy, IPMs are central to inverters used in solar, wind, and energy storage systems. They help maximize power module efficiency improvements while managing harsh environments and variable loads typical in renewable setups. This ensures stable energy conversion and grid integration.

Industrial motor drives remain a major application, with IPMs used extensively in automation, robotics, and HVAC systems. They offer precise control and switching loss reduction, supporting smarter, more energy-efficient industrial processes.

Emerging trends include IPMs designed for charging infrastructure and smart grid technologies. These roles demand ultra-reliable and high-voltage intelligent power modules that can withstand frequent cycling and high-frequency operation, critical for fast EV charging and grid stability.

HIITIO’s focus on automotive-qualified and high voltage power modules ensures solutions that fit these evolving application needs, including their advanced 1200V IGBT power modules tailored for high-performance EV and industrial uses (Econo Dual 3H 1200V 450A IGBT Power Module).

Future Outlook and Emerging Directions in Intelligent Power Modules

Looking ahead, the future of intelligent power modules (IPMs) is being shaped by several exciting trends. Integration of AI and predictive maintenance features is set to enhance device reliability and reduce downtime by enabling real-time fault detection and adaptive control. This smart capability is especially valuable in critical applications like electric vehicle inverters and renewable energy inverters.

We’re also seeing a strong push toward ultra-compact designs combined with higher voltage ratings—1200V and above—to meet demands for smaller, more powerful power modules. This trend is driven by advances in wide bandgap semiconductors like SiC and GaN, which allow IPMs to handle higher voltages with greater efficiency and better thermal performance.

Sustainability plays a big role in future IPM development, focusing on energy-efficient materials and manufacturing processes that reduce environmental impact. Manufacturers are balancing these eco-friendly goals while ensuring high reliability and performance standards.

Of course, challenges remain. Designers must carefully balance integration complexity, cost, and system performance. Achieving advanced features without driving up costs or compromising reliability is a key hurdle for scaling these next-generation power modules.

Products like the EconoPIM3 1200V 50A IGBT Power Module exemplify this future direction—combining automotive-qualified designs with high voltage and compact form factors to meet evolving application demands in EVs, renewables, and industrial drives.

How HIITIO is Addressing These Trends

HIITIO stands out with its expertise in developing high-performance semiconductor power modules tailored for today’s demanding applications. By focusing on advanced wide bandgap semiconductors, including SiC IPM trends, HIITIO is driving innovations that meet the rigorous needs of electric vehicle IPM and renewable energy inverters IPM sectors. Their commitment to automotive-qualified IPM designs ensures modules meet stringent reliability and efficiency standards critical for traction systems and industrial motor drives IPM.

View HIITIO IPMs SiC GaN Modules

HIITIO’s solutions specifically target key industry challenges, such as switching loss reduction IPM and high-frequency power modules operation. This approach supports customers looking for power efficiency improvements and EMI mitigation while maintaining thermal management and robust system integration. Their product lineup, featuring options like the 1200V 450A IGBT module with integrated FWD and NTC, highlights a commitment to high-voltage intelligent power modules that deliver reliable performance in electric vehicle inverters and renewable energy setups.

By combining advanced packaging technologies with intelligent gate drivers, HIITIO enables ultra-compact designs and supports emerging trends in charging infrastructure and smart grid applications. Their efforts align perfectly with future power electronics trends, balancing cost, integration complexity, and performance to meet U.S. market demands for sustainable, efficient, and powerful IPM solutions across multiple industries.