Cost vs Performance Analysis Are SiC Modules Worth the Investment

Explore if SiC power modules justify their cost with superior efficiency reliability and performance versus silicon IGBTs in key applications.

If you’re weighing the cost vs performance of power modules, the rise of silicon carbide (SiC) technology is impossible to ignore. SiC modules come with a higher upfront price compared to traditional silicon IGBTs, but their game-changing efficiency, thermal management, and power density can unlock significant system-level savings and longer-term value. So, are these advances worth the investment? In this post, we’ll cut through the noise with clear insights into where SiC modules really make an impact—and when sticking with silicon might still make sense. Let’s dive in.

Understanding SiC Power Modules: Basics and Key Advantages

If you’ve heard about SiC power modules and wondered what sets them apart from traditional silicon IGBTs, you’re not alone. Simply put, Silicon Carbide (SiC) modules are a newer breed of power devices, mostly MOSFET-based, designed to handle higher voltages and switch faster than conventional silicon IGBT modules.

What Are SiC Modules?

- SiC MOSFETs replace silicon IGBTs in many applications, offering faster switching and better efficiency.

- Unlike IGBTs which rely on silicon, SiC modules use a wide bandgap semiconductor material—silicon carbide.

- This difference in core material brings several key benefits in power electronics.

Core Material Benefits

- Wider bandgap: SiC’s bandgap is about three times wider than silicon’s, which translates to improved electrical performance and ability to operate at higher voltages.

- Higher thermal conductivity: SiC efficiently conducts heat, which means devices can handle higher operating temperatures with less cooling.

- Faster switching speeds: SiC MOSFETs switch much faster than traditional IGBTs, reducing switching losses and enabling higher frequency operation.

- Higher voltage handling: SiC modules excel at handling voltages of 600V to over 1200V without sacrificing performance.

Performance Highlights

- Reduced switching and conduction losses: SiC modules minimize both switching losses (at turn-on and turn-off) and conduction losses, boosting overall device efficiency.

- Higher operating temperatures: Thanks to better thermal characteristics, SiC modules run hotter without damage, simplifying thermal management.

- Greater power density: Faster switching allows designs to shrink in size, packing more power into smaller modules with fewer passive components.

In , SiC power module efficiency and thermal advantages make them a compelling choice where performance and reliability matter. But how do these benefits stack up against traditional silicon in terms of cost? Let’s dig into the SiC vs Si IGBT comparison next.

Direct Cost Comparison: SiC vs. Silicon IGBT Modules

When it comes to upfront costs, SiC power modules currently carry a premium. Typically, they cost 2 to 3 times more per ampere than traditional silicon IGBT modules. This price gap largely comes down to challenges in substrate quality and more complex manufacturing processes unique to silicon carbide.

| Cost Factor | SiC Modules | Silicon IGBT Modules |

|---|---|---|

| Price per Ampere | 2-3x higher | Standard |

| Substrate Material | Expensive, complex | Mature, cost-effective |

| Manufacturing Complexity | High | Lower |

| Wafer Size | Smaller, growing | Large and mature |

However, trends are promising. As manufacturers scale to larger wafers and improve production yields, SiC module costs are expected to drop steadily through 2030. This makes the investment increasingly attractive over time, especially for high-performance applications.

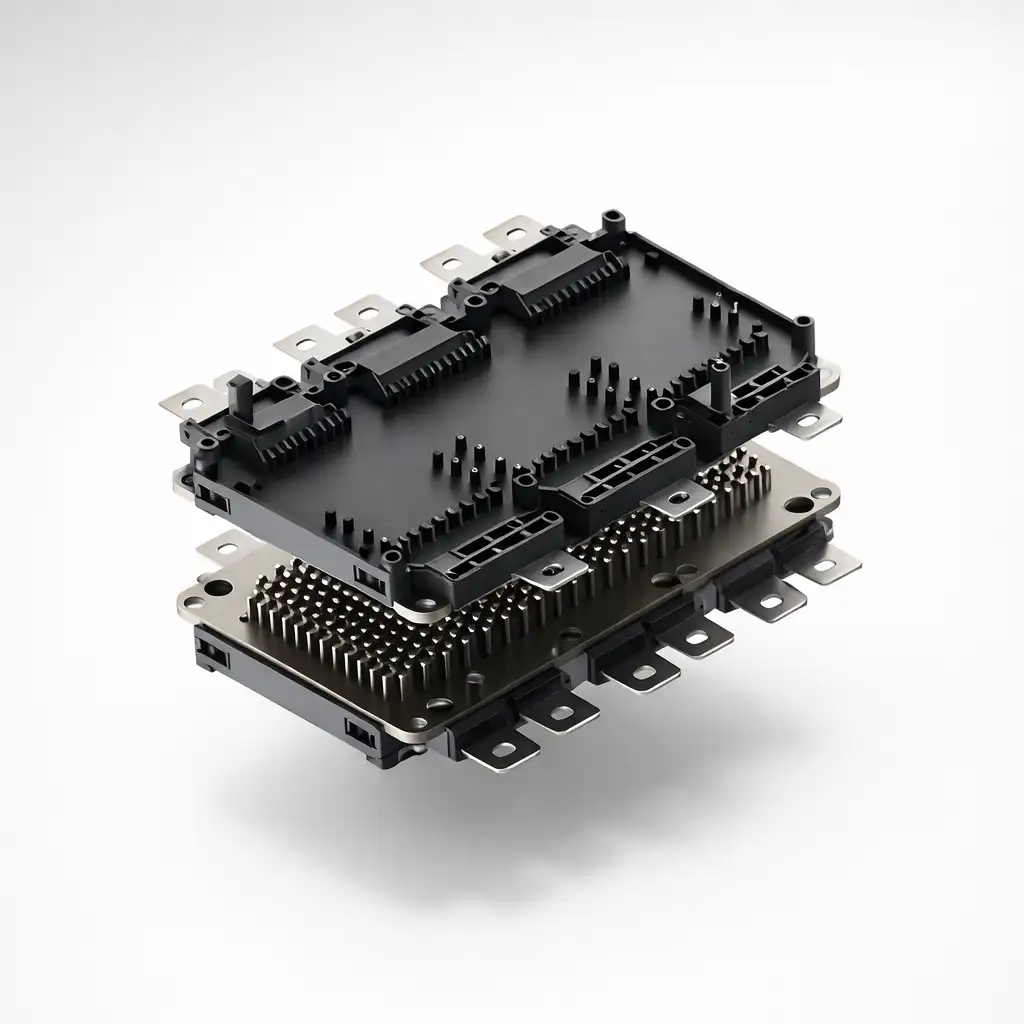

For example, HIITIO’s 1200V 200A SiC power module showcases how advanced manufacturing helps balance cost and performance in today’s market.

In , while SiC modules start with a higher price, ongoing technological progress is narrowing the gap versus silicon IGBT modules, positioning SiC as a smart long-term investment for US industries focused on cutting-edge efficiency and reliability.

Performance Breakdown: Where SiC Excels

Silicon carbide (SiC) power modules stand out for their impressive performance benefits compared to traditional silicon IGBT modules. Here’s where SiC really shines:

- Efficiency Gains: SiC modules reduce switching and conduction losses, boosting overall system efficiency by 2-5%. This means less energy wasted as heat and more power delivered where it’s needed.

- Thermal Management: Thanks to higher thermal conductivity, SiC modules run cooler and tolerate higher operating temperatures. This cuts down on cooling requirements and allows for smaller, lighter heatsinks, simplifying system design and reducing costs.

- Power Density and Size: The ability to switch faster and operate at higher voltages means systems can be designed with fewer and smaller passive components. This results in a much more compact footprint and lighter modules—key advantages for applications like electric vehicles and renewable energy inverters.

- Reliability Features: SiC’s superior power cycling capability and high-temperature stability contribute to longer service life and lower failure rates. This translates to less downtime and maintenance, making SiC a dependable choice for demanding industrial motor drives and other critical applications.

If you’re searching for a robust option with cutting-edge thermal resistance and high voltage handling, SiC modules clearly outperform traditional silicon-based modules. For example, high-performance modules like the 2400V 1700A high-voltage IGBT power module can be compared against their SiC counterparts to evaluate specific application fits.

Total Cost of Ownership (TCO) Analysis

When considering SiC power modules, it’s important to look beyond the upfront price and focus on the total cost of ownership. SiC delivers significant system-level savings thanks to reduced energy consumption, which means lower electricity bills over time. Its higher efficiency also allows for smaller passive components like inductors and capacitors, trimming both size and weight. This leads to lighter, more compact designs that lower installation and operational costs.

In real-world scenarios, the ROI for SiC modules often becomes clear in high-utilization applications. For example, electric vehicles benefit from extended driving range and faster charging, directly translating into customer value and cost savings. Similarly, renewable energy inverters reduce energy losses and cut energy bills, helping users recover the initial SiC investment faster.

However, the break-even point depends heavily on the application. SiC justifies its premium in systems where efficiency and reliability bring clear savings—like EVs, industrial drives, or solar inverters. For low-power, cost-sensitive setups, traditional silicon IGBT modules may still be more economical over the product lifecycle.

For a closer look at top-tier SiC modules designed for long-term value, check out the advanced 1200V 600A SiC power module from HIITIO. Its optimized design highlights how investing in SiC can lower total cost of ownership while improving overall system performance.

Application-Specific Evaluation: Is SiC Worth It?

When deciding if SiC power modules are worth the investment, it really depends on the application. For electric vehicles and charging, SiC shines by extending driving range, enabling faster charging times, and allowing for more compact onboard power systems. These benefits come from SiC’s higher efficiency and thermal performance, which directly translate to better battery utilization and smaller cooling setups.

In the renewable energy sector, particularly solar and wind inverters, SiC modules offer higher efficiency and a smaller system footprint. This means more power output for the same size and less heat to manage, which can lower both initial and operational costs. For industrial motor drives and uninterruptible power supplies (UPS), SiC’s reliability and thermal stability improve longevity and reduce maintenance expenses, making it a smart long-term choice.

However, silicon IGBT modules still hold strong in some areas. For low-power, cost-sensitive, or low-frequency applications, traditional silicon IGBTs often remain the more economical option. These applications usually don’t benefit noticeably from SiC’s advanced advantages, so the higher upfront cost doesn’t justify switching.

For projects needing robust power modules at standard efficiency, HIITIO’s 1100V 600A Easy 3B IGBT Power Modules provide a balanced solution. But for high-performance needs, especially in EV or renewable energy systems, SiC modules deliver clear value that offsets their premium price.

Overall, the choice between SiC and silicon modules boils down to balancing performance gains against cost, considering the specific demands of your application.

Reliability and Long-Term Value from HIITIO SiC Modules

When it comes to power module reliability, HIITIO SiC modules stand out thanks to advanced features like superior high-voltage insulation and low thermal resistance. These allow the modules to handle high voltage power demands while efficiently managing heat, which is crucial for long-term stable operation.

HIITIO’s SiC power modules also offer excellent power cycling capability and robust high-temperature stability. This means they can endure frequent on-off cycling and harsh thermal conditions without degrading quickly, supporting a longer service life compared to traditional silicon modules.

Designed with durability in mind, HIITIO prioritizes consistent performance even under demanding industrial or EV conditions. This focus results in real-world benefits like minimized downtime and extended system longevity, making their SiC modules a smart investment for applications where reliability is non-negotiable. Check out options like the E0 1200V 150A SiC Power Module to see how HIITIO’s designs translate to lasting value.

Future Outlook: SiC Adoption and Price Trajectory

The future of Silicon Carbide (SiC) power modules looks promising, especially as key market drivers push adoption higher. The electric vehicle (EV) boom is a major catalyst, with more automakers relying on SiC MOSFET advantages to improve range, charging speed, and overall efficiency. At the same time, renewable energy expansion—think solar and wind inverters—is driving demand for higher-efficiency, smaller-footprint power modules.

Regulatory pressure for better energy efficiency across industries is another important growth factor. Stricter efficiency standards encourage switching from traditional silicon IGBT modules to wide bandgap semiconductors like SiC that offer superior performance and thermal management.

Price trends also support wider SiC adoption. While SiC modules currently cost about 2-3 times more per ampere than silicon counterparts, ongoing improvements in substrate manufacturing, scaling to larger wafers, and better yields are steadily driving costs down. Experts project that SiC modules could reach near cost parity with silicon IGBTs before 2030, making them accessible to a broader range of applications.

For businesses in the U.S. market, the strategic choice is clear: adopting SiC today can future-proof designs, improve system efficiency, and deliver a solid return on investment as SiC price trends continue improving. Companies ready to upgrade power modules will benefit from staying ahead of the curve in power module reliability and thermal performance, helping them meet evolving efficiency regulations now and in the future.

For those exploring SiC options, reviewing advanced modules like HIITIO’s reliable 1200V power modules (1200V 300A IGBT power module) can provide a smart starting point for understanding current market capabilities.