What Is the Purpose of a Power Module

Discover the purpose of a power module with HIITIO’s guide highlighting efficient power conversion, high power density, and advanced thermal management.

A power module is a compact electronic unit designed to efficiently manage and convert electrical energy in various applications. At its core, it combines multiple power semiconductor devices, such as insulated-gate bipolar transistors (IGBTs) or silicon carbide (SiC) diodes, into a single, integrated package. This integration reduces space and improves performance compared to using separate discrete components.

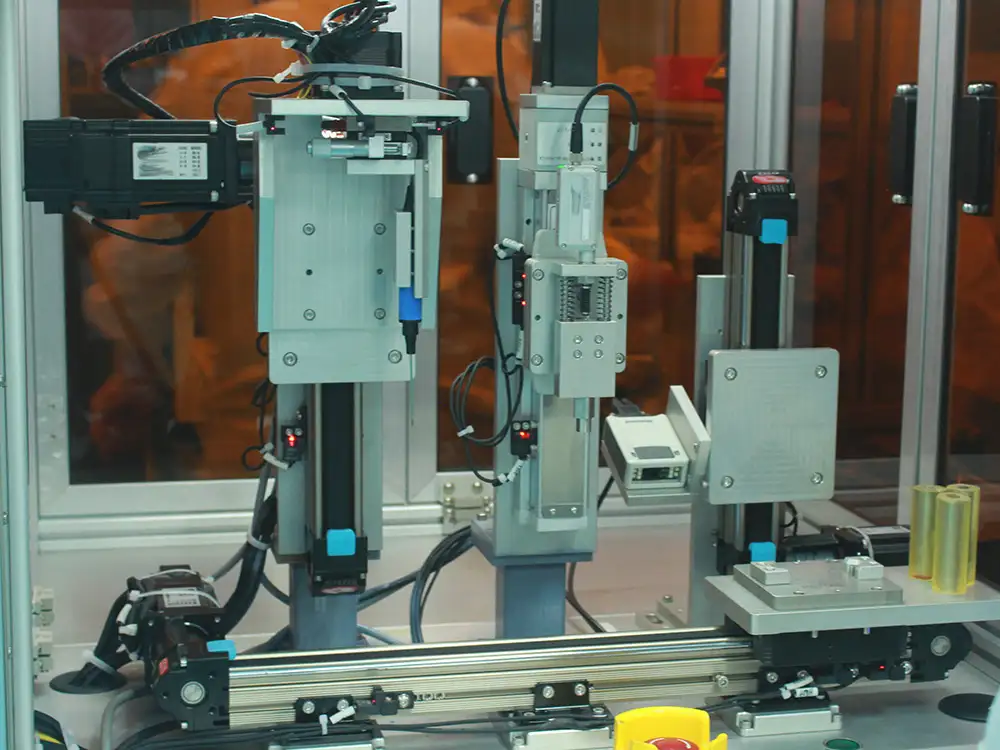

The construction of a power module typically includes:

- Power semiconductors like IGBT chips or GaN (gallium nitride) transistors that handle high-power switching

- A thermal management baseplate to dissipate heat effectively and maintain optimum operating temperatures

- Electrical connections and substrates that provide reliable current paths and mechanical support

- Encapsulation materials that protect components from environmental factors and electrical interference

By combining these elements, power modules offer compact, reliable solutions for converting and controlling power. Their design allows for efficient energy conversion with reduced losses, making them essential in high-power electronics.

How Power Modules Differ from Discrete Components or Full PSUs

Power modules stand out because they combine several key components—like IGBT power modules, SiC diodes, or GaN semiconductor modules—into a single, compact package. Unlike discrete components, which are individual parts you have to connect yourself, power modules are pre-assembled and designed to work together efficiently. This means less wiring hassle, improved reliability, and better thermal management thanks to features like integrated baseplates that help dissipate heat.

Compared to full power supply units (PSUs), power modules focus specifically on the power conversion and control part rather than providing a complete power solution with all the supporting electronics. This makes them ideal for applications needing high-power switching devices, like motor drive inverters or DC-DC converter modules, where space and efficiency matter.

In short, power modules strike a balance between the simplicity of discrete components and the all-in-one nature of PSUs, offering streamlined integration and better performance for complex, high-power uses—especially in industries like EV traction applications and industrial UPS rectifiers.

The Primary Purpose: Power Conversion and Control at Scale

At its core, the power module’s main job is to efficiently convert and control electrical energy on a large scale. Whether it’s stepping voltage up or down or switching power between circuits, power modules handle these tasks with precision and reliability.

These modules use components like IGBT power modules and SiC diode integration to manage high-power switching without wasting energy. This efficient energy transformation is key in systems like DC-DC converter modules and motor drive inverters, where maintaining performance and minimizing heat is critical.

In practical terms, power modules help keep the flow of electricity smooth and stable, enabling everything from EV traction applications to industrial UPS rectifiers to run efficiently. Their ability to manage large currents and voltages cleanly makes them indispensable for any application that demands high power control without compromising on size or efficiency.

Why Integration Matters: Tackling High-Power Challenges

When dealing with high-power applications, integration in a power module is a game-changer. Instead of using separate components like IGBT power modules, SiC diode integration, or GaN semiconductor modules scattered on a board, everything is packed into one compact unit. This tight integration helps handle high currents and voltages more reliably.

Here’s why this matters:

Better Heat Management: Integrated power modules often use a thermal management baseplate, which spreads and removes heat much more effectively than discrete parts. This means they run cooler and last longer.

Reduced Size and Wiring: Combining multiple components into one module cuts down on space and wiring complexity. That’s a big plus in compact setups like EV traction applications or industrial UPS rectifiers where space is at a premium.

Improved Efficiency: With integrated DC-DC converter modules and motor drive inverters designed to work seamlessly together, energy losses drop. Efficient power conversion saves money and reduces the heat you have to deal with.

Simplified Design and Maintenance: Instead of managing multiple separate devices, engineers get a ready-to-go solution. This not only speeds up development but also makes troubleshooting easier.

By integrating components like the IGBT power module, SiC diodes, and GaN technology inside one smart package, power modules can meet the high-power demands in ways that discrete parts simply can’t. That’s why integration is central to pushing the limits of power electronics today.

Real-World Applications: Where Power Modules Shine

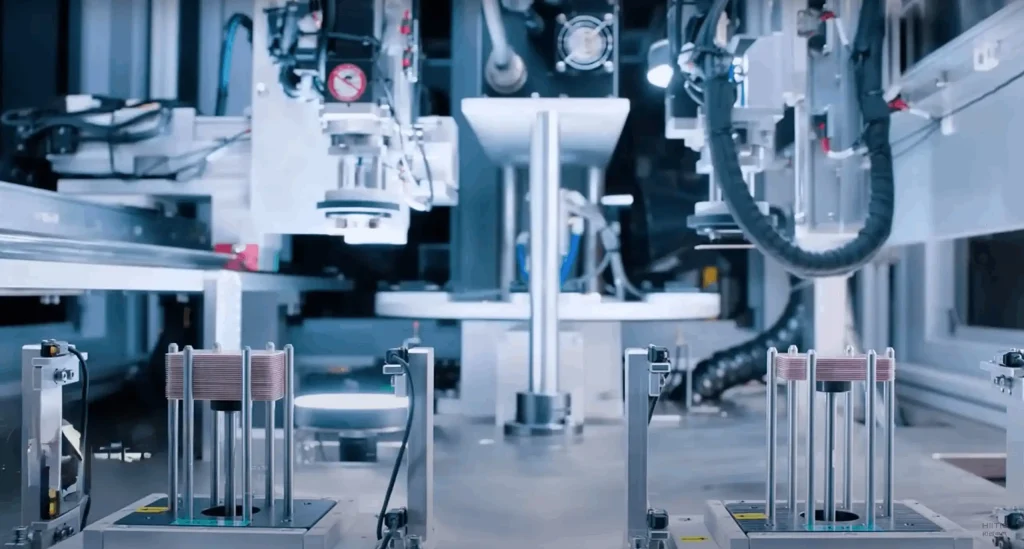

Power modules play a crucial role across many key industries in the U.S., especially where efficient power conversion and control are non-negotiable. One of the biggest areas is electric vehicles (EVs). Here, IGBT power modules and SiC diode integration help drive motor inverters for smooth, reliable EV traction applications. These modules manage high-power switching devices efficiently, enabling better range and performance.

In renewable energy, power modules are also essential. Solar inverters and wind turbine controllers use DC-DC converter modules and thermal management baseplates to handle fluctuating energy flows while keeping systems stable and efficient. Industrial UPS rectifiers benefit too by ensuring a consistent, clean power supply during outages.

Other industries like manufacturing, aerospace, and data centers rely on power modules for high-density computing and motor drives. Emerging tech such as GaN semiconductor modules promises even higher efficiency and power density, meeting the growing demand for compact, reliable power electronics.

In short, power modules are at the heart of modern electrical systems—from EVs and renewables to industrial and computing applications—making them indispensable for advancing energy efficiency and power management in the U.S. market.

Emerging Uses in AI and High-Density Computing

Power modules are becoming crucial in AI and high-density computing, where efficient power delivery and thermal management are key. These systems demand high-power switching devices like IGBT power modules and GaN semiconductor modules that can handle heavy loads without overheating.

In AI data centers and edge computing setups, power modules help maintain stable voltage and current levels in dense server racks, improving reliability and performance. The integration of SiC diode technology and advanced DC-DC converter modules also enhances efficiency, reducing energy loss and cooling needs.

For U.S.-based businesses investing in AI infrastructure or HPC, using advanced power modules means supporting higher processing speeds while controlling power consumption. This translates into cost savings and a lower environmental footprint—two priorities for companies managing large-scale computing resources.

The future will likely see even greater adoption of power modules in AI hardware as the demand for faster, smarter computing grows.

Key Benefits and Specifications: Why Choose Power Modules

Power modules offer clear advantages for engineers and designers working on high-power electronics. They combine important components like IGBT power modules, SiC diode integration, and motor drive inverters into a single, easy-to-use package. This integration simplifies design and speeds up development.

Here’s why power modules stand out:

Benefits

- Compact and Efficient: Modules pack multiple high-power switching devices into a small footprint. This saves space and boosts efficiency.

- Improved Thermal Management: Built-in thermal management baseplates help maintain safe operating temperatures, increasing reliability.

- High Reliability: Pre-tested modules reduce the risk of component failure and make quality control easier.

- Simplified Assembly: Less wiring and fewer solder joints mean faster and cleaner production.

- Scalable Performance: Whether it’s a DC-DC converter module or an industrial UPS rectifier, power modules handle high-current and high-voltage needs smoothly.

Key Specifications to Look For

| Specification | Typical Range/Features | Why It Matters |

|---|---|---|

| Voltage Rating | 600V to 1700V | Supports various power levels |

| Current Rating | 10A to 600A | Manages heavy loads efficiently |

| Switching Frequency | Up to 100 kHz | Controls power conversion speed |

| Thermal Resistance | Low (with integrated baseplate) | Ensures stable operation under load |

| Semiconductor Type | IGBT, SiC, GaN | Affects efficiency and switching speed |

| Packaging | Module with heat sink or baseplate | Simplifies cooling and installation |

For U.S.-based applications like EV traction systems, renewable energy setups, or industrial motor drives, these benefits translate into better product performance and faster time to market. Choosing the right power module means focusing on reliability, efficiency, and ease of integration — all essential for modern power electronics challenges.

Trade Offs and Selection Tips

Choosing the right power module means balancing a few important factors to fit your specific needs. Here’s what I keep in mind when helping customers pick the best option:

Efficiency vs. Cost

Higher efficiency modules like those with SiC diode integration or GaN semiconductor technology often cost more upfront but save money over time through lower energy loss. If your project runs continuously or deals with high power, investing in efficiency pays off.

Power Rating and Size

Make sure the power module matches your system’s voltage and current requirements. Oversizing adds unnecessary cost and space, while undersizing risks failure and overheating. Pay close attention to the thermal management baseplate to handle heat effectively.

Switching Speed and Frequency

Modules featuring high-power switching devices like IGBT power modules or GaN-based modules switch faster, supporting better performance in applications like motor drive inverters or DC-DC converter modules. Higher speed may increase complexity and cost, so evaluate your application’s needs carefully.

Thermal Management

Good heat dissipation is critical for reliability. Look for designs with robust thermal management solutions, especially if your application involves continuous heavy load like EV traction applications or industrial UPS rectifiers.

Integration Level

Integrated modules can simplify design and reduce assembly time. However, fully integrated options sometimes limit customization or flexibility. Consider how much control you want versus the ease of use.

Selection Tips

- Start by listing your key application needs: power level, environment, efficiency targets, and budget.

- Compare IGBT power modules with newer SiC and GaN options to see which aligns best with your goals.

- Review datasheets for thermal specs to avoid overheating problems down the road.

- Consider supplier support and proven success—HIITIO, for example, leads with reliable solutions tailored for the US market.

Keep these trade-offs and tips in mind to confidently choose a power module that fits your project perfectly, without surprises.

HIITIO’s Role Leading Innovation in Power Modules

Why Partner with HIITIO China’s Power Module Pioneer

When it comes to power modules, HIITIO stands out as a leader, especially in the U.S. market looking for reliable, high-performance solutions. As one of China’s top power module manufacturers, HIITIO combines advanced technology with practical designs that meet the demanding needs of industries like EV traction applications, industrial UPS rectifiers, and motor drive inverters.

Here’s why HIITIO is a smart choice:

- Cutting-Edge Integration: HIITIO uses the latest in SiC diode integration and GaN semiconductor modules to boost efficiency and reduce heat, addressing common challenges in high-power switching devices.

- Robust Thermal Management: Their power modules feature optimized thermal management baseplates, which keep devices cooler and running longer, a key concern for U.S. engineering teams working in tough environments.

- Wide Range of Applications: Whether you need DC-DC converter modules for renewable energy systems or reliable IGBT power modules for industrial settings, HIITIO offers versatile, proven solutions.

- Innovation and Quality: HIITIO invests heavily in research and development, ensuring its products meet global standards with consistent performance and durability.

- Responsive Support: For U.S. customers, HIITIO provides strong technical support and quick turnaround times, making integration smoother and minimizing downtime.

Partnering with HIITIO means you leverage a company that understands the complexities of modern power electronics while delivering power modules suited for the high demands of the American market. Their leadership in innovation helps us keep pace with the best in efficiency and reliability, crucial for today’s fast-evolving industries.

Ready to Upgrade Your Power Electronics with HIITIO?

Whether you’re designing next-generation EV traction systems, industrial motor drives, or high-density computing solutions, HIITIO’s semiconductor power modules deliver the efficiency, reliability, and thermal performance your projects demand. Our advanced IGBT, SiC, and GaN power modules are engineered specifically for the U.S. market, combining cutting-edge technology with proven durability. Don’t settle for off-the-shelf solutions that don’t quite fit—partner with a leader in power module innovation. Contact HIITIO today to discuss your specific requirements, request technical specifications, or get a customized quote.